Measurement Sensors

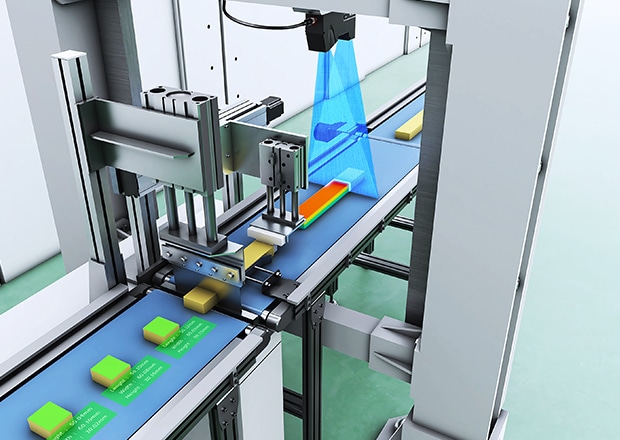

Dimension Measurement

Displacement Measurement

Measurement Sensors for the Food and Beverage Industry

The food and beverage industry faces numerous challenges due to mandatory rules and regulations governing the production of perishable goods. KEYENCE offers precision measurement sensors that inspect food and beverage products and help customers deliver the highest quality goods to end consumers.

Get detailed information on our products by downloading our catalog.

View Catalog![Automated Measurement and Inspection Examples [Food and Containers]](/img/asset/AS_138240_L.jpg)

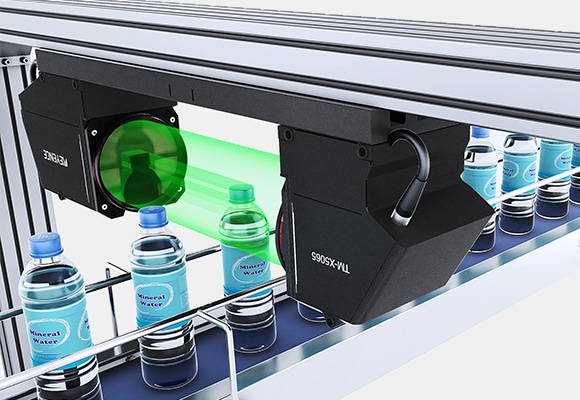

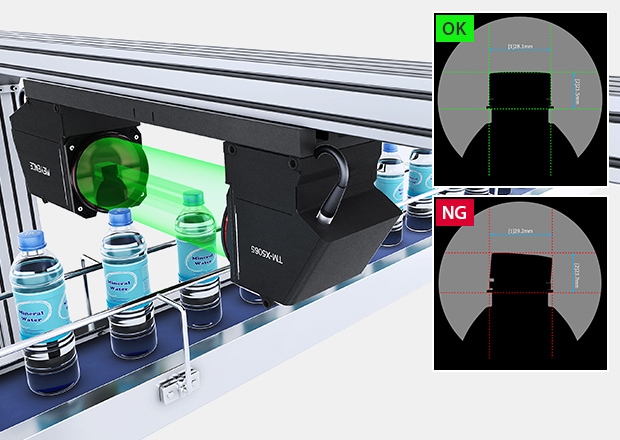

Bottle Cap Inspection

Inline inspection is possible for plastic bottles and bottle caps. The telecentric optical system eliminates the influence from ambient light for guaranteed inspection stability in any environment.

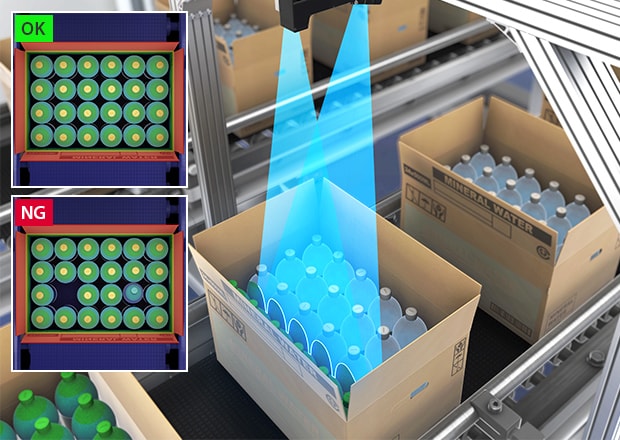

Beverage Bottle Counting

The LJ-X8000 Series can be used to count the number of products being packaged. Acquiring height data makes it possible to detect packaging conditions such as whether different capacity bottles are being packed and if the bottles are buckling.

Beverage Can Buckling Inspection

Inspection of beverage cans for dents and scratches can be performed for a thousand different colors and glosses. Acquiring 3D data ensures stable inspection even for glossy, curved metal surfaces, which are difficult to capture images with conventional cameras.

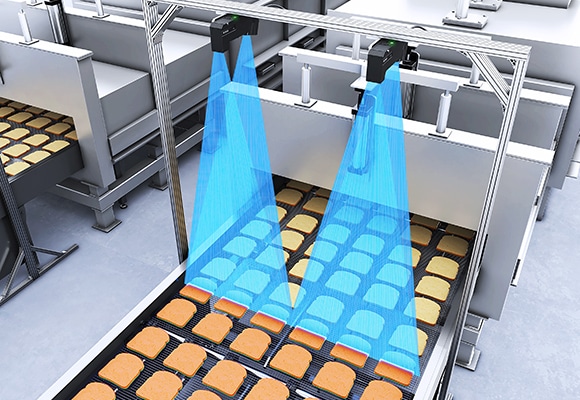

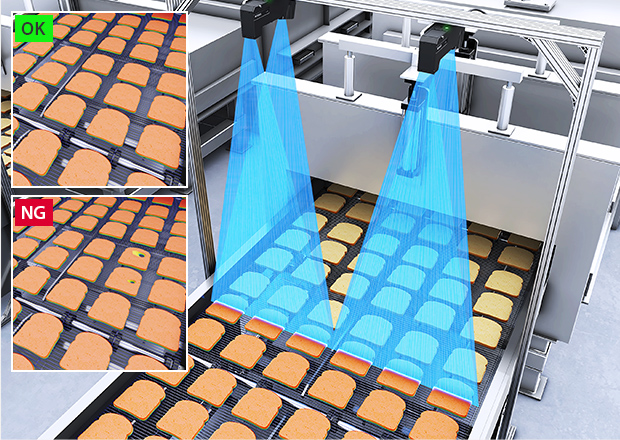

Bread Slice Shape Inspection

Sliced bread must be inspected for correct shape and thickness, as holes in bread can lead to complaints when used for sandwiches. The height-based images captured by the LJ-X8000 Series enable reliable detection of holes and incorrect shapes.

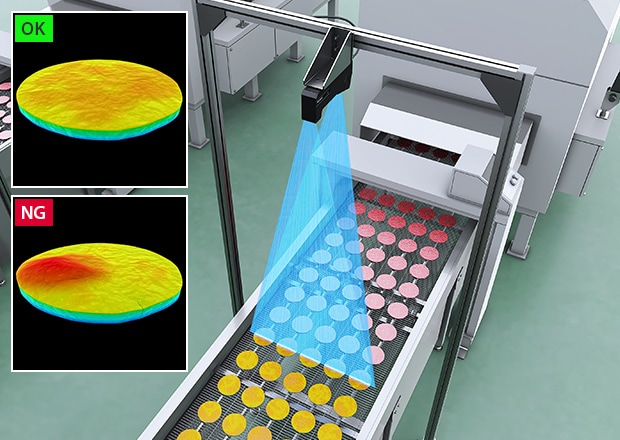

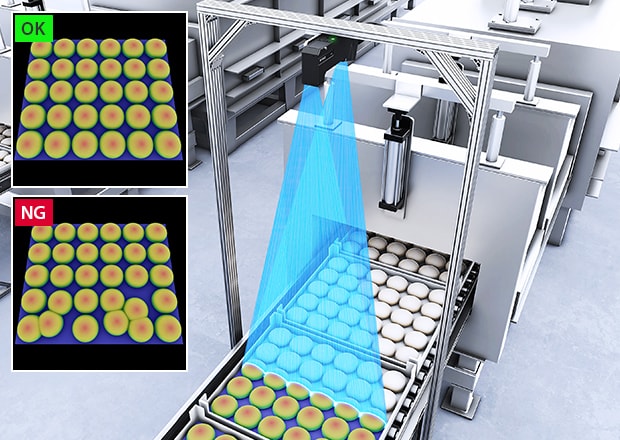

Hamburger Patty Shape Inspection

Hamburger patties used in fast food establishments have a fixed cooking time, and patties that are too thick will not cook properly, and those that are too thin will become overcooked. The height-based images captured by the LJ-X8000 Series enable reliable inspection of the patties thickness.

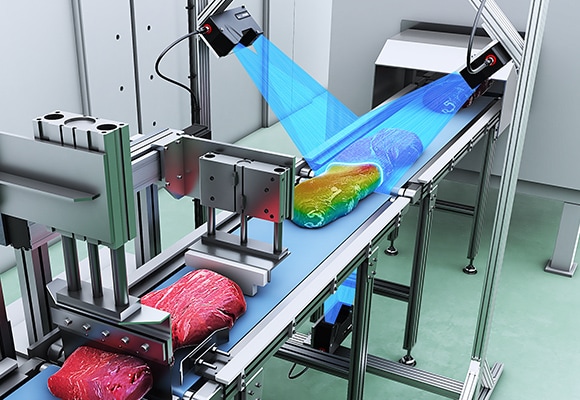

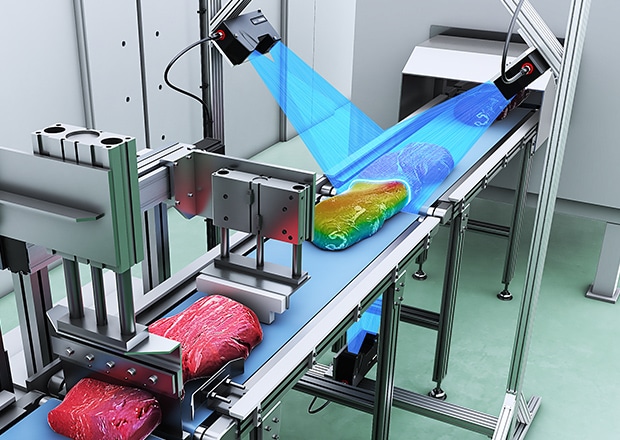

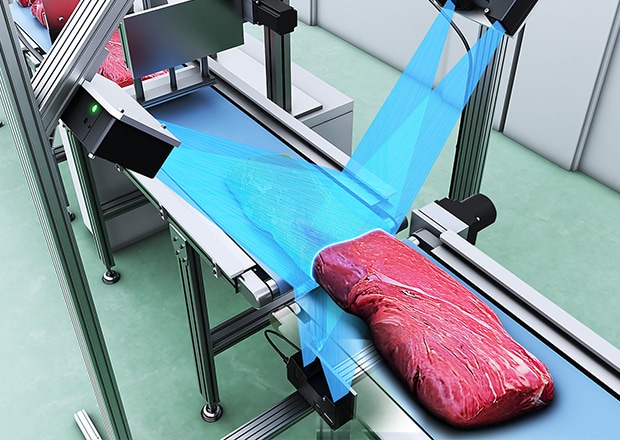

Meat Slicer Position Control

Proper positioning makes it possible to cut fillets into predetermined sizes. Sending length, width, volume, and other information obtained from the profile to the cutting equipment ensures fillets are cut into uniform weights regardless of their shape.

Cheese Volume Measurement

Measurement of the length, width, and cross-sectional area of cheese is performed, and the data is then sent to the sorting device. Cutting products into equal portions helps improve the yield rate and prevent complaints from consumers.

Dough Position Monitoring

By monitoring the conveyor, the system makes it possible to ensure the dough is evenly lined up and not overlapping or unevenly placed on the conveyor. Baking overlapping dough results in uneven baking and the product must be discarded. The dough can also damage the oven itself. Constant monitoring can therefore help reduce overall costs.

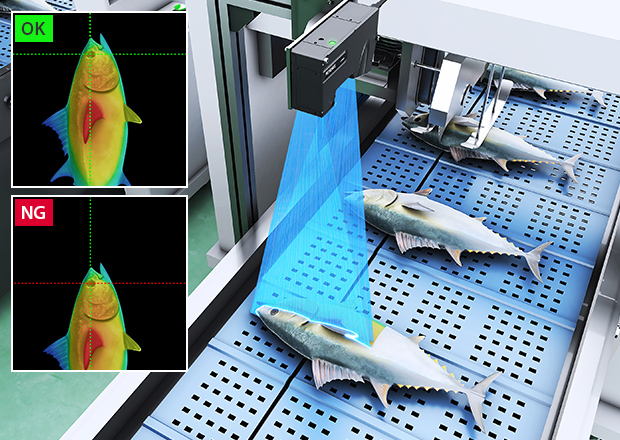

Fresh Fish Processing Equipment Positioning

Easily automate fish processing by sending the size and position data of fresh fish to processing machines such as fresh fillet machines and head-cutting machines. The LJ-X8000 Series ensures stable detection without being affected by color or ambient light.

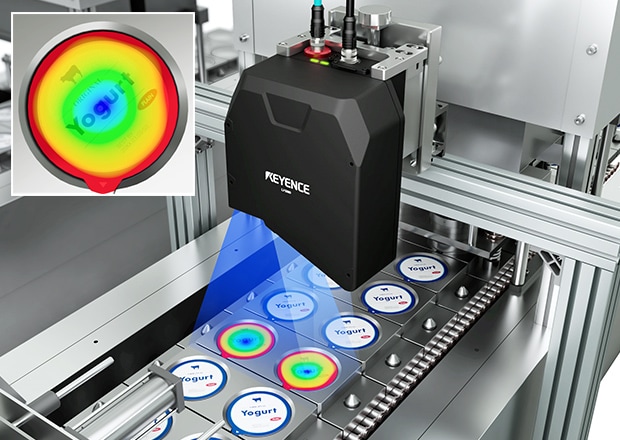

Lid Heat Seal Inspection

A proper heat seal is not only important to the container integrity but also to the overall freshness of whatever is inside the container. The LJ-S8000 Series 3D Laser Profilers can ensure that the heat seal is applied correctly to each container.

Importance of Precision Measurements in the Food and Beverage Industry

Consistent quality is paramount in food production, and precision measurement sensors govern the entire process. Different sensors are used to ensure the right ingredients are added in correct proportions, all temperatures are accurately maintained, and all products are adequately packaged.

However, precise measurement in the food and beverage industry doesn’t relate to product quality alone. The use of precise measurement sensors also optimizes the use of ingredients and resources, leading to waste reduction—overuse of ingredients adds to unnecessary costs, while underuse leads to substandard products.

Thus, measurement systems help optimize the food and beverage production process, minimize waste and associated costs, and ensure the quality and safety of products.

We’re here to provide you with more details.

Reach out today!

3D Snapshot Sensors for Optimizing Food and Beverage Processing Applications

KEYENCE 3D laser snapshot sensors can be used in inline food applications for improved quality and efficiency. Whether for increasing throughput or automating manual processes, our line of laser snapshot sensors delivers easy-to-use, non-contact, and high-performance measurement sensors to all aspects of the food processing industry.

With increasing consumer demands for food and beverage products that meet their changing dietary and lifestyle requirements, manufacturers need measurement/inspection solutions that can support them with speed, accuracy, and reliability.

Snapshot Sensors for Quality Control in Food and Beverage Production

Using snapshot sensors in the food and beverage industry helps with quality control in product manufacturing. The capability to create a three-dimensional profile of the target under inspection allows manufacturers to identify contaminants like stones, metal fragments, and glass in raw materials. These scanning and inspection solutions can also be used to cut meat products into appropriate sizes, ensuring every portion meets quality and dimensional requirements.

Snapshot sensors can also be integrated into existing production lines to verify filling levels in containers. Inspecting for punctures, improper sealings, and other defects in packaging are other uses of 3D snapshot sensors.

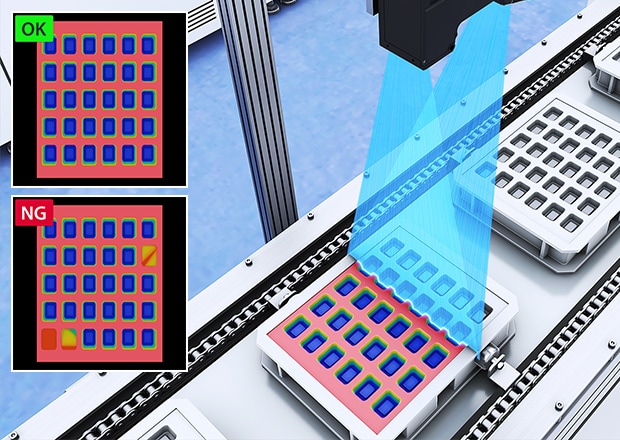

Product Quality Assurance Inspection

The food and beverage industry relies heavily on various non-contact sensors to inspect the quality of its products. However, most systems rely on color contrast to detect defects or missing parts. Because product materials can vary in color, it can make it difficult for various cameras to detect defects and differentiate them from expected patterns.

KEYENCE’s 2D/3D Profilers, such as the LJ-X8000 Series, alleviate these problems. For example, they can detect dimensional differences in case of missing or even misaligned products. These inspection sensors use laser displacement technology to measure the height, width, and other physical properties of a particular product. This makes them more reliable than contrast sensors, as they’re unaffected by color.

Food and Beverage Packaging Inspection

The food and beverage industry often relies on packaging that’s either easily deformed or damaged by physical sensors, which only underlines the importance of precise, non-contact measurements.

Sensor selection mostly depends on the type of packaging. For example, the LJ-X Series measures variance down to the single-digit µm level, making it perfect for inspecting shrink-wrapping tears, lid height differences, and burrs.

Likewise, confocal displacement lasers, such as KEYENCE’s CL-3000 Series, are capable of handling various surface conditions. This guarantees consistent and dependable cap seating inspection, regardless of the material or color of the cap.

Of course, the packaging inspection doesn’t end there. Our sensors offer innovative solutions for almost every type of non-contact packaging inspection. In the end, packaging protects and preserves the food and beverage, and it has to be adequately inspected before it’s dispatched to the end consumer.

Discover more about this product.

Click here to book your demo.

Applications and Examples

- Bottle Inspection Sensors

- Sensors for Food Sorting

- Sensors for Meat Processing

- Sensors for Cheese Portioning and Inspection

- Candy Measurement Sensors

- Automated Poultry Inspection Sensors

- Missing Item Inspection Sensors

- Label Quality Inspection Systems

- Dough Processing Sensors

- 3D Final Product and Packaging Inspection

- Package Seal Inspection

Reduce Scrap with Proper Inspection

Automated inspection with non-contact sensors offer real-time defect detection that’s much faster, more reliable, and consistent compared to manual inspection. These systems can detect various issues in the early stages of production, thereby reducing the number of defective products that reach packaging and shipment.

Improving Safety and Efficiency with 3D Laser Snapshot Sensors in Food Manufacturing

To meet the quality requirements of consumers and regulatory standards, manufacturers need reliable technology to help carry out measurements and inspections of food and beverage products. Our laser snapshot sensors for the food and beverage industry come with features and functions that support safety and efficiency requirements.

The LJ-S8000 Series features an imaging speed of as fast as 0.2 seconds and repeatability of 0.3 µm, making for ultra-high-speed and ultra-high-accuracy inline inspections. The sensor product can be installed onto existing equipment, such as an index table or an industrial robot, without fear of instability through vibration. Our snapshot sensors can also be used as stand-alone inspection solutions.

If you’re looking to enhance the quality of your product, the cost-effectiveness of your manufacturing process, and reduce waste with proper inspection, don’t hesitate to contact KEYENCE. We offer innovative solutions for the food and beverage industry, and our professional staff can answer any inquiries related to integrations and implementations into pre-existing production lines.

Contact us today for more information about our 3D laser snapshot sensors!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity