Measurement Sensors

Dimension Measurement

Displacement Measurement

2D Profile Measurement

When looking for the best way to perform profile measurements, there are several important factors to consider, including the type of measurement system and the installation environment. Selecting equipment that doesn't adequately meet your needs can lead to insufficient precision and increased man-hours during production.

This site is designed to help users determine the best way to perform measurements with confidence regarding a 2D profile measurement system.

Choose Case of 2D Profile Measurement

Applications of Laser Snapshot Sensors in Profile Measurement

2D profile measurement is essential for measuring shapes, dimensions, and surface profiles with high precision in industry applications. This type of measurement is widely used in quality control, assembly verification, and machining, where detailed dimensional analysis is critical. More recently, laser snapshot sensors like KEYENCE’s LJ-S8000 Series have become increasingly popular in profile measurement applications due to their high speed and ease of use.

While they also take 3D profiles, laser profilers like KEYENCE’s LJ-X8000 Series have emerged as a leading technology for 2D profile measurement, offering reliable and accurate assessments that improve efficiency in various manufacturing processes.

2D Profile Measurement: How to Measure 2D Shapes

2D profile measurement relies on capturing the shape's dimensions, contours, 2D measurements, and other physical properties—such as flatness—in two-dimensional space using 1D or 2D laser displacement sensors in a single scan. Using displacement laser technology allows for exceptionally efficient dimensional mapping of complex shapes or instances that require real-time 2 dimensional profiling. Accurate measuring starts with a clear understanding of the process, which includes selecting an adequate measuring system, adequate calibration of measuring tools, positioning, data capture, and data analysis.

For this guide, we'll focus solely on the selection of the appropriate measuring systems, which depend on the specific requirements of your project—or, in other words, which type of laser displacement sensor you should use.

We’re here to provide you with more details.

Reach out today!

2D Measurements of Shapes Using 1D Laser Displacement Sensors

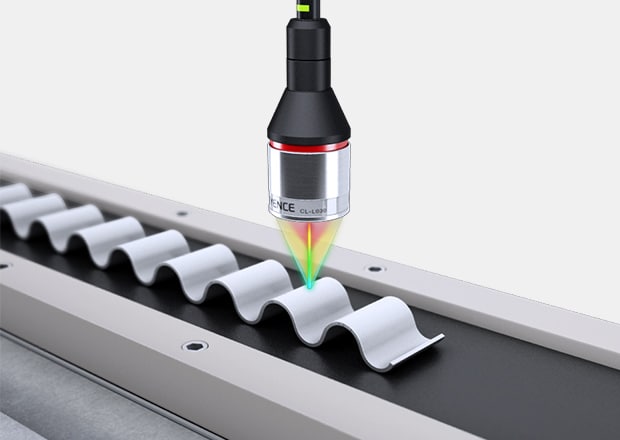

1D laser displacement sensors are specifically designed to measure the distance from the sensor to the target surface. In their most basic setup, 1D laser displacement sensors work by creating a series of 1D measurements, which are then compiled into a 2D profile.

During scanning, the sensor projects a laser beam towards the target surface, which then reflects the light back to the sensor. The sensor calculates the distance based on the angle of reflection or properties of the light returned to the sensor, based on sensor used. As stated above, measuring a 2D profile is done either by moving the sensor or the object being measured. This allows the laser sensor to take a series of 1D measurements and form a 2D profile of the object.

Their ability to measure the distance between the sensor and the surface makes them perfect for gauging changes in height or detecting surface irregularity. So, if your primary concern lies in measuring variations in flat or slightly curved surfaces, a 1D sensor might be sufficient. An example application would be measuring a 2D profile of aluminum fins.

- Shapes can be measured at a higher precision with 1D laser displacement sensors than with 2D laser displacement sensors.

- A mechanism for moving the sensor head and/or target is required.

- Vibrations from when the sensor head or target is moved cause measurement errors.

High-Speed Measurements with Laser Snapshot Sensors

The high-speed capabilities of laser profilers like KEYENCE’s LJ-X8000 Series for 2D profile measurement enable them to handle the fast-paced demands of modern production lines. These sensors can capture 3200 points of data per profile, allowing for continuous, non-stop inspection without slowing down production. Multiple 2D laser profilers can also be combined for larger targets. This capability minimizes downtime and increases inspection efficiency, making laser profilers for 2D profile measurement a practical solution for high-throughput environments.

Alternatively, a 3D Snapshot sensor like KEYENCE’s LJ-S8000 Series captures a full 3D image of an object in a single scan, enabling the measurement of multiple dimensions, angles, and profiles simultaneously. This technology is ideal for inspecting complex shapes or objects that are stationary. The high-resolution images provided by 3D snapshot sensors allow for precise measurements and detailed analysis of surface features.

2D Profile Measurement of Shapes Using a 2D Laser Displacement Sensor

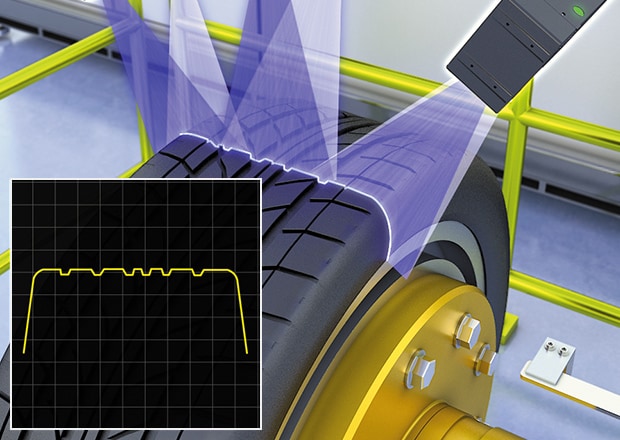

Things aren't as simple when it comes to capturing and measuring objects with intricate details or complex contours. And that's where 2D Laser Displacement Sensors come in. Instead of emitting a single point like 1D laser displacement sensors do, 2D laser displacement sensors project a line onto the target surface.

The laser line is reflected off the surface and picked up by the built-in receiver system, which then processes the shape of the reflected line to the object's 2D profile by using cutting-edge algorithms. This allows the 2D displacement laser sensor to capture an entire 2D profile of an object in a single scan, without movement. A good example of this would be profile-measuring tire tread grooves.

The cross-sectional shape of locations where the laser hits can be obtained. High-speed sampling makes it possible to achieve stable detection even if the workpiece moves.

- Shapes can be measured without moving the sensor head and target.

- The shape of large targets can be measured by installing multiple sensor heads.

What is 2D Profile Management?

Both 1D and 2D laser displacement sensors use various software tools to analyze the collected data and present it as a coherent 2D profile of a target surface. Not only that, but the softwares also provide detailed information that can be used to identify potential issues and anomalies.

And that's where 2D and 3D profile management comes into play, as it centers on harnessing the said data's potential. This involves storing the analyzed data about a particular 2D profile, setting benchmarks that are compared to future scans and 2D measurements, and allowing easier quality control and maintenance—including calibrations and maintenance of the measuring system itself.

Precision in Shape Measurement with Laser Snapshot Sensors

Profilers and snapshot sensors for 2D/3D laser profile measurement applications are invaluable, including edge profiling, gap and flush measurements, and flatness inspections. By providing clear, high-resolution 2D and 3D images, these sensors are especially useful in sectors where fine details matter. Their ability to capture profiles in real time allows manufacturers to inspect each product’s dimensions and ensure compliance with strict specifications.

Precision in 2D shape measurement is vital for industries that require precise two-dimensional measurement and quality control of components. Laser profilers, like the LJ-X8000 Series, are a cutting-edge solution for this need, providing highly precise measurements of 2D shapes and profiles through laser triangulation technology. These sensors capture accurate cross-sectional profiles of objects in an instant, making them invaluable for applications where even the smallest discrepancies in shape or alignment can affect functionality or assembly.

The LJ-S8000 Series 3D Laser Profile Sensors from KEYENCE, offer high-speed imaging and precision for accurate profiling of even the smallest features. These sensors also offer imaging speeds down to 0.2 seconds and repeatability of 0.3 µm, so they are ideal for high-speed inspection applications requiring both accuracy and speed.

We’re here to provide you with more details.

Reach out today!

Related Downloads

![Key Technology and Application [Profile measurement]](/img/asset/AS_108927_L.jpg)

Conventionally, profile measurement and 3D measurement have been difficult to perform inline. This guide uses practical examples to explain how accurate, high-definition measurement and inspection can be easily achieved with the latest laser profilers.

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity