Measurement Sensors

Dimension Measurement

Displacement Measurement

Measurement Sensors for the Automotive Manufacturing Industry

Precision is critical in the automotive industry. Everything, from engine components and paneling to the interior, undergoes meticulous design and manufacturing processes to ensure the maximum performance, reliability, and safety of the vehicle.

To help with this, KEYENCE sensors provide the automotive manufacturing industry with reliable solutions for a variety of precise measurement and inspection needs at every stage of production. From component manufacturing to body assembly, our sensors drive quality and process control improvements that help suppliers/manufacturers meet the increasingly high standards for vehicle safety and customer satisfaction.

Choose Case of Measurement Sensors for the Automotive Manufacturing Industry

Importance of Precision Measurements in the Automotive Manufacturing Industry

The automotive industry has a major responsibility, as its products directly impact the safety of its consumers. In fact, anything less than 100% reliability under normal operating conditions can cost lives and massive financial losses in recalls.

That is why the industry can’t afford to overlook precision measurements in every component or part that goes into making a vehicle. That’s where precision measurement sensors come into play—they ensure that every component and part is correctly cut, milled, molded, extruded, and assembled before a vehicle is sent to the next stage of production.

We’re here to provide you with more details.

Reach out today!

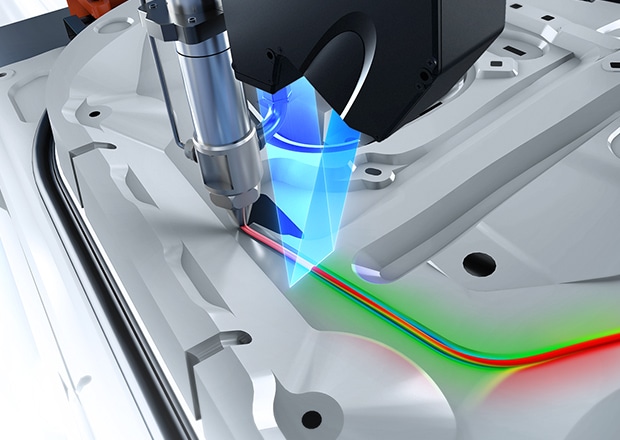

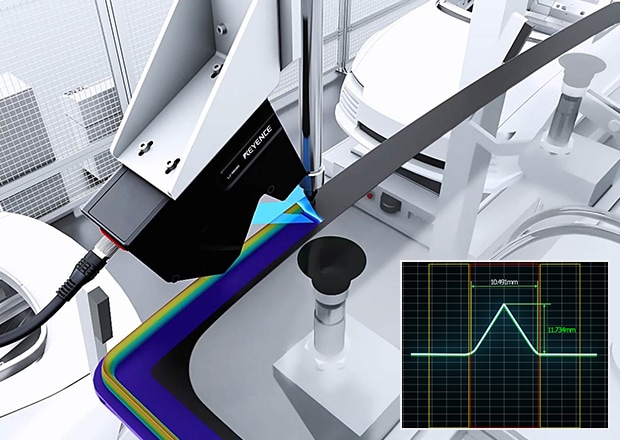

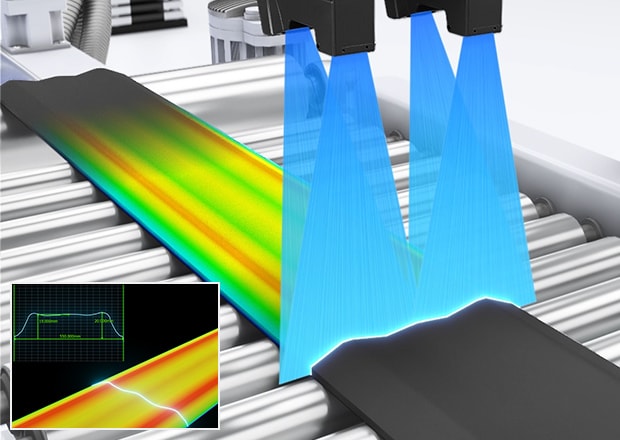

Sealant Shape Inspection

Laser profilers can measure the shape of a sealant bead, in addition to height and width. By checking the shape, you can catch defects (such as bubbles or collapse) prior to installation and improve seal performance.

Weld Inspection

Check weld quality immediately post-welding using a 2D/3D laser profiler. Detect defects such as pits or burn-throughs stably without worrying about glare or material color causing errors.

Door Gap and Flush Measurement

Measure door gap and flush simultaneously with the LJ-X8000 Series laser profiler. The high resolution and imaging capability make it possible to measure curved, glossy surfaces accurately regardless of car color.

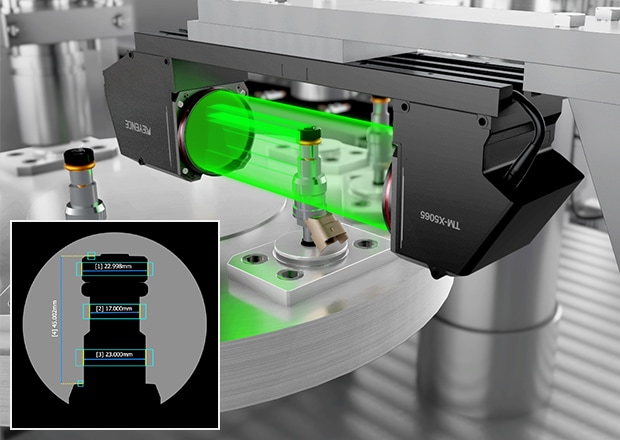

Piston Head Dimensional Measurement

Measurement of piston head outer diameters and clearance can be performed inline. Measure targets with diameters up to 120 mm 4.72″ with a single sensor head.

Multi-Point Diameter and Height Measurement of Injectors

Simultaneous multi-point measurement is possible for a wide variety of injectors. Because there is minimal distortion throughout the entire field of view, targets of any size can be measured accurately, even if they take up the full window.

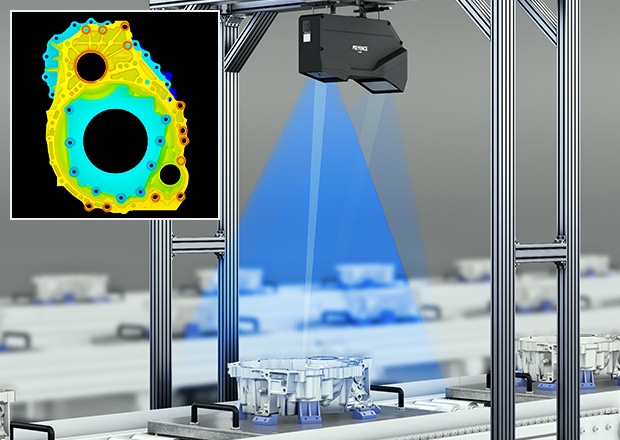

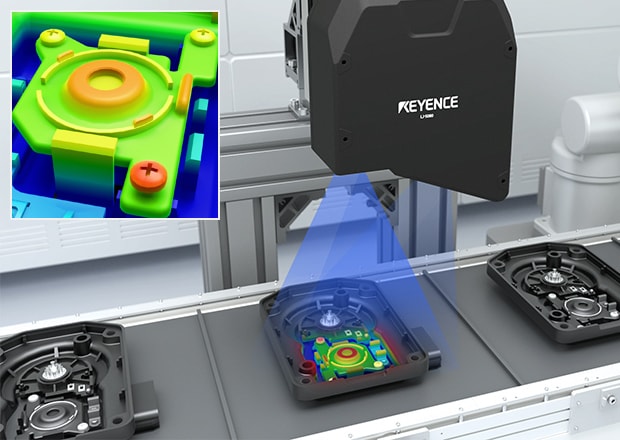

Sealing Inspection on Die-Cast Automotive Components

Proper sealing is key in all types of automotive assembly. Our 3D Laser Snapshot Sensors are able to scan large die-cast components and confirm that proper amounts of sealant or other sealing materials are present before assembly is continued.

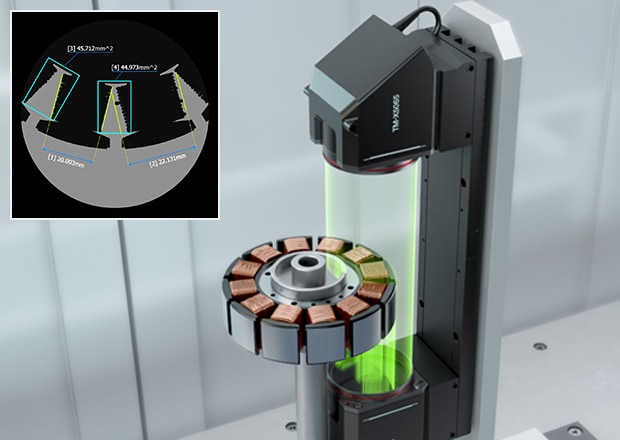

Motor Winding Defect Inspection

The dual telecentric optical system’s large depth of field means inspection can be performed for an entire winding, including the winding width, even for targets that take up the entire field of view.

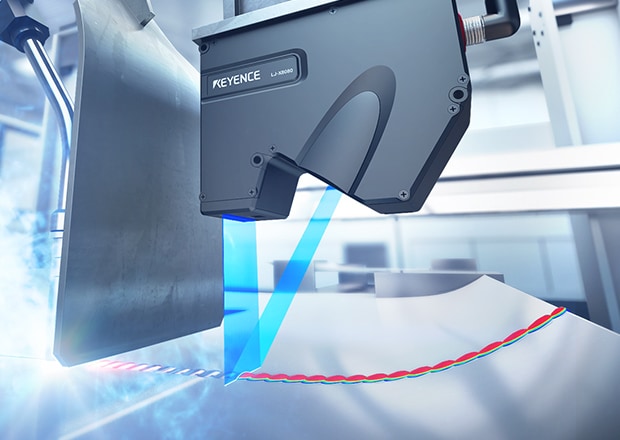

Windshield Coating Inspection

The LJ-X8000 Series inspects any breaks in, the amount of, and the position of urethane foam applied to the glass. The ultra high-speed sampling makes it possible to inspect the whole circumference with a detailed pitch.

Brake-Disk Runout Measurement

The CL-3000 Series can perform accurate, non-contact measurements of brake disks rotating at high speeds.

The CL Series can be reliably used in an inline manner thanks to its exceptional measurement stability.

Screw Seating Inspection for Plastic Molded Products

Screw seating inspections are possible for plastic molded parts with the LJ-S8000 Series 3D Laser Snapshot Sensor. The sensor scans the surface shape of a target and uses the height information for inspection. Since the scanner is built into the sensor head itself, no additional resources or time are required for auxiliary parts, such as stages and encoders. Inline inspections are possible simply by attaching the LJ-S8000 Series to the equipment.

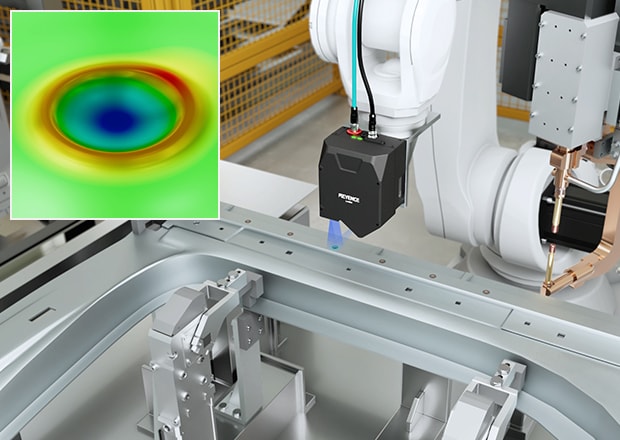

Spot Welding Nugget Inspection

Spot welding nugget shape and appearance inspection are possible with the LJ-S8000 Series 3D Laser Snapshot Sensor. The sensor can be mounted on a robot for inspection at any angle or location. The sensor head also includes a scanner that stabilizes inspections with no need to worry about robot vibrations or linearity.

Thickness and Width of Tread and Sidewall

The LJ-X8400 measures the thickness and width of rubber immediately after extrusion. Inspecting the full profile of the extrusion, rather than a single point, enables users to capture additional insight including the maximum/minimum height or the height at the center.

Stroke Monitoring on Presses

Depending on the behavior of the press stroke, drawing may not be performed correctly and may cause cracks to form. Using a long-range laser displacement sensor makes it possible to shorten the time spent setting conditions.

3D Snapshot Sensors for Automotive Manufacturing Applications

3D snapshot sensors are used for different applications in the automotive manufacturing industry. They help during the inspection of components for defects such as scratches, cracks, and missing parts. Snapshot sensors can also measure and verify dimensional accuracy. When assessing the quality of surface finishes, snapshot sensors are used to create three-dimensional profiles of targets.

Apart from quality control, these sensors are also valuable during component assembly. They help in the measurement of the flushness of surfaces and gaps between body panels. Automotive manufacturers deploy them as reliable measurement sensors to reduce scrap and associated costs.

Overall, snapshot sensors in the automotive industry help manufacturers increase efficiency, improve product quality, and reduce operational costs.

Industrial Snapshot Sensors for Vehicle Inspections

Laser snapshot sensors find use at critical control points, including inspections, in vehicle manufacturing. A single detail missed could mean premature product failure in the field. To avoid these quality issues and comply with different regulatory standards, measurement and inspection systems such as laser snapshot sensors are built with features and functions that guarantee precision-based results. These sensors, including 2D/3D laser profilers, ensure that manufacturers maintain high standards.

Whether for inspecting for scratches or unevenness in body panels, printed circuit boards, or deviations from quality standards, 3D snapshot sensors for automotive manufacturing industry applications help with quality and operational efficiency.

Curious about our pricing?

Click here to find out more.

3D Part Inspection

Every part and component has to be inspected for defects before entering the assembly line. The automotive industry mostly relies on 2D/3D laser profilers, such as LJ-X8000 Series, to scan the part for any defects or deviations from predetermined parameters.

These sensors, often used for quality inspections, can detect defects and deviations down to the micron level, thus ensuring that only high-quality, per-spec products reach the assembly circuit. This way, only high-quality parts and components are installed, further enhancing the quality of the product.

Vehicle Body Inspection

Welding has extensive applications in the automotive industry, particularly when it comes to paneling, brackets, covers, springs, seats, hinges, etc. A typical vehicle has around 5,000 weld spots, and inspecting these by hand in a robot-run and fast-moving production line is impossible.

That’s why welding robots use 2D/3D laser profilers to locate the weld seam, track and guide the process along the seam, and subsequently inspect the weld. This significantly enhances the efficiency of the welding process.

Automotive and Parts Manufacturing

KEYENCE also provides non-contact measurement solutions for quality assurance automation for parts manufacturing. These are typically comprised of vision systems and 2D/3D laser profilers, as well as confocal laser displacement sensors to inspect each part during the manufacturing process and the subsequent quality assurance.

These solutions are often implemented into fully automated control systems and provide inline inspection of manufactured parts, ensuring that only the highest-quality, defect-free parts reach subsequent assembly lines.

Discover more about this product.

Click here to book your demo.

Types of Sensors for the Automotive Manufacturing Industry

As previously stated, the automotive industry relies on a number of different sensors to ensure precision measurement of parts, components, and machine assemblies. These range from using confocal laser displacement sensors, such as CL-3000 Series, to measure rotor runouts to using advanced laser profilers, such as LJ-X8000 Series, to inspect the critical dimensions of connecting rods.

Of course, these aren’t the only measurement sensors the automotive industry relies on. KEYENCE offers other precision measuring sensors aimed at the automotive industry, like laser micrometers, 3D scanners, and various laser displacement sensors.

Applications and Examples

Enhance Automotive Quality and Control with LJ-S8000 Series Snapshot Sensors

The high precision associated with the measurement sensors and quality assurance solutions KEYENCE offers significantly enhances the quality of the end product and thus ensures driver and passenger safety. KEYENCE LJ-S8000 Series of laser snapshot sensors are designed to help automotive manufacturers perform a wide range of inline inspections on different parts and components. With the LJ-S8000 Series there’s no need for external lighting, a stage, or encoder because the system comes with a built-in laser light source and scanning mechanisms.

With quick imaging speeds of 0.2 seconds and repeatability of 0.3 µm, inspections of dimensions, appearance, shape, and other features are super-fast and accurate.

For more information about our laser snapshot sensors for the automotive manufacturing industry, contact us today. Our experienced staff will answer all inquiries you have about integrating KEYENCE solutions into your existing manufacturing and processing lines.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity