Measurement Sensors

Dimension Measurement

Displacement Measurement

Bead Inspection in Automotive Manufacturing

Applying sealant (sealer, primer) such as liquid gaskets (CIPG, FIPG, etc.) or urethane foam is an indispensable step in the process of assembling engine parts and ECU cases, sealing chassis parts, and securing glass panes onto car bodies.

Currently, dispenser robots are commonly used to apply sealant in a bead shape with a high aspect ratio along the shape of the target automatically. Achieving highly airtight seals, however, requires continuous and stable sealant coating. This section introduces inspection solutions to ensure high-quality automatic sealant dispensing.

Get detailed information on our products by downloading our catalog.

View Catalog

Bead Shape Inspection

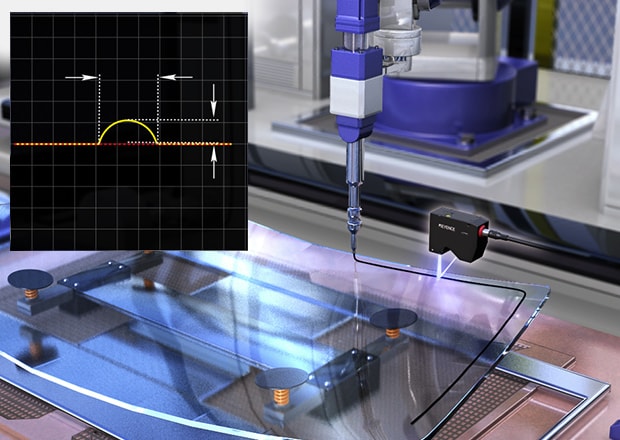

In the manufacturing of automotive parts like sunroofs and windows, the use of a bead inspection device is crucial to ensuring the presence of adhesive beads along the entire designated path without any breaks or gaps. Instead of relying on manual inspection applications that can be time-consuming and error-prone, automated sealant bead inspection systems are desired. The deployed solution should easily be integrated into the existing bead dispenser and configurable for both pedestal and robot mounting.

Our high-performance laser profiling sensors can be used to track the movement of a dispenser robot to achieve stable inspection of bead shape immediately after coating.

2D Cross-Sectional Shape Inspection of Sealant (Sealer, Primer) During Glass Pane Assembly

The process of mounting glass windshield panes onto car bodies requires preventing defective sealant (sealer, primer) coating that may cause rust, stiffness, or degredation due to the ingress of water.

Adopting the LJ-X8000 Series into the process of automatic coating of urethane foam onto the glass panes with a dispenser robot enables inspection of the entire circumference immediately after coating by tracking the robot. Ultra-high-speed sampling in fine pitches is used to inspect the cross-sectional shape immediately after coating to monitor for defects.

The system ensures stable measurement even on targets with vastly different heights and reflectivity, such as curved glass panes and sealant for which stable measurement is difficult when using conventional cameras.

3D Shape Inspection of Sealant (Sealer, Primer) on Engine Parts

-

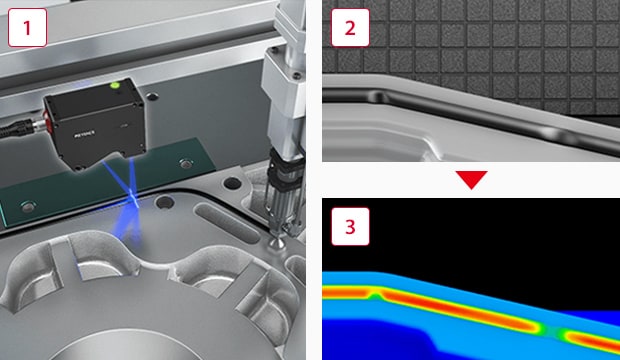

1Example measurement setup

-

2Enlarged view of measured section

-

33D image processing (Example of unacceptable product: An insufficient or interrupted bead is detected.)

For automotive components, the prevention of ingress and leakage of oil and water is required. To achieve this, it is important to ensure airtight joining and sealing through stable coating of sealant (sealer, primer) or liquid gaskets.

Get detailed information on our products by downloading our catalog.

View Catalog

3D Bead Inspection for High-Precision Applications

Checking for the presence and continuity of sealant beads is one automotive manufacturing process requiring high precision. Inspections need to be carried out inline to allow operators and managers to monitor the performance of dispensing equipment and sealant distribution quality.

Accurate bead inspection results require the use of 3D inspection equipment. 3D-based solutions can inspect the width, height, volume, and shape of dispensed beads. They work by capturing three-dimensional profiles of inspection targets, including depth data. Full profile imaging means accurate detection of gaps, breaks, excess sealant, and insufficient sealants.

Non-contact measurement inspection and speed are other benefits offered by 3D bead inspection technologies.

Importance of Sealant Bead Inspection

Here are some areas where sealant bead inspection is important:

Product Quality and Reliability

Inspecting bead sealant for presence and continuity is crucial to product quality and reliability. Beads properly added around automotive windows and sunroofs, for example, ensure these sections of a vehicle are watertight, preventing water intrusion.

Vibrations and Noise

These are eliminated or significantly lowered when gaps, for instance, between the door and the door frame are properly sealed. In addition, spaces in the underbody panels must be tightly sealed to prevent water from entering the auto interior.

Safety

This is another reason why inspecting sealants is essential. Without proper seals in place, heat can get into the wrong chamber, igniting and spreading fire. Ensuring accurate bead dispensing also helps avoid recalls or returns from defects caused by improper seals.

We’re here to provide you with more details.

Reach out today!

Weld Bead Measurement in Automotive and Industrial Applications

Inspecting for weld beads is required in many automotive and industrial manufacturing processes.

Automotive

The body-in-white (BIW) stage, where the vehicle’s body frame is joined together, requires adequate inspection of integrated parts. Issues during this stage could impact the structural integrity of car bodies. Situations like this not only pose safety risks to the field user but also can be damaging to the manufacturer’s reputation for product reliability.

Industrial Applications

Inspecting for quality weld seams in pressure vessels holding fluids and gasses ensures that contained materials don’t leak or evaporate. Any hit to the structural integrity of weld beads can lead to serious consequences, such as the escape of hazardous substances and fire explosions.

Using suitable weld bead measurement equipment lends safety to industrial applications and products.

Laser Displacement Sensors for Accurate Bead Shape Inspection

Laser displacement solutions such as laser profilers are reliable equipment for accurate bead inspection. With fast-speed capability and advanced imaging techniques, laser sensors can perform inline inspections and communicate results to downstream systems.

KEYENCE offers different laser-based inspections for automotive and industrial applications.

Our high-speed 2D/3D laser profiler LJ-X8000 Series allows real-time measurement of the cross-sectional shape of a continuous sealant bead immediately after coating by tracking the fast movements of the dispenser robot. This system ensures stable inspection for defects such as height variations, insufficient coatings, or unevenness of the sealant without being affected by the color, shape, or material of the target or sealant, or by reflections from metal parts.

Moreover, using an image processing system to process the cross-sectional shape profile obtained with the LJ-X8000 Series enables 3D shape inspection for more precise shape, height, width, volume, and other aspects.

For more information about our laser displacement sensors for precision-based glue bead inspections, contact us today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity