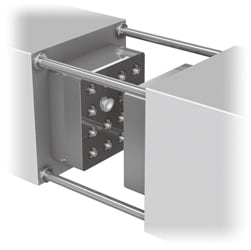

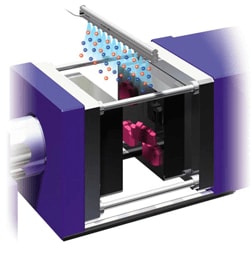

Molded Resin Parts Remaining in Mold

Molded parts sometimes stick to and remain in the mold due to the electrostatic charge generated by friction with the mold.

Due to miniaturization and thinner designs, molded parts are lighter and stick more easily. When the shape is complicated, the amount of surface friction with the mold increases and the parts are charged more easily. Furthermore, high-speed molding machines use faster injection speeds, resulting in a larger electrostatic charge and increasingly higher risk of part remaining in molds.

Conventional countermeasures

Measure against defects caused by foreign particles: provide a cover.

- The effect is small.

Measure against remaining parts: install a sensor.

- The sensor can only detect the occurrence of remaining parts. The parts must be removed manually.

Countermeasures with static eliminators (ionizers)

An ionizer eliminates static electricity to prevent the adhesion of foreign particles and remaining parts. It can reduce waste of material costs and improve the yield rate.

Improvements and Effects

Words from the worksite

Reduced material disposal cost due to defects caused by foreign particles

Material cost: $10 x 200 pieces/month x 12 months = $24,000/year

Since remaining parts may lead to a risk of mold breakage due to double closing, the measure is also effective for reducing the cost of equipment maintenance.