Blurry Ink in Screen Printing of Electronic PCBs

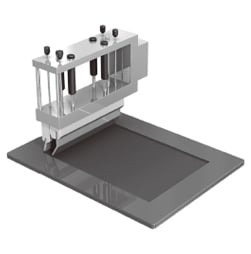

In screen printing, electrostatic charge is generated by the friction between the screen and squeegee or when the screen is removed.

When the screen is separated from the PCB, some ink clings to the screen and makes spots or splashes. As a result, the ink blurs during printing.

Squeegee: a tool that looks like a rubber wiper. It is used to apply the ink evenly so that the ink is pushed through the holes in the screen to print on the board.

Conventional countermeasures

Conventional static eliminator

- The effect is uncertain.

- Maintenance requires a lot of work and managing daily performance is difficult.

Countermeasures with static eliminators (ionizers)

The blower type static eliminator improves the effect of static electricity elimination and reduces defective printing.

Improvements and Effects

Words from the worksite

Reduced disposal cost due to defective printing

Disposal cost due to defective printing: $500/month x 12 months = $6,000/year

The labor cost for installation are much lower compared with the bar type.