Measurement Sensors

Dimension Measurement

Displacement Measurement

Measurement Sensors for the Medical and Pharmaceutical Industry

The integration of advanced measurement sensors and systems into the medical and pharmaceutical industry ensures the safety, efficiency, and quality of healthcare tools and devices. The fact that even the most minute deviation in medical devices can often mean the difference between life and a fatal outcome only underscores the importance of precise measurement.

To ensure high levels of precision and accuracy, the medical and pharmaceutical industries rely on precise measurement sensors for various inspections and quality control checks. A high level of precision significantly affects the reliability of both medical equipment and pharmaceutical products, which in turn improves patient outcomes.

Get detailed information on our products by downloading our catalog.

View Catalog![Automated Measurement and Inspection Examples [Medical Devices]](/img/asset/AS_119876_L.jpg)

Importance of Precision Measurements in the Medical and Pharmaceutical Industry

As stated, precision is crucial in the medical and pharmaceutical industries, and even the slightest deviation in the dimensions or composition of equipment and drugs can lead to disastrous results. Because of that, the industry demands adherence to strict standards and protocols that ensure that each product is of the highest possible quality and safety specification.

Measuring sensors, such as thrubeam sensors and 2D/3D profilers, are therefore necessary to achieve higher levels of precision. They allow manufacturers to control the production process and ensure unparalleled quality control of their products.

We’re here to provide you with more details.

Reach out today!

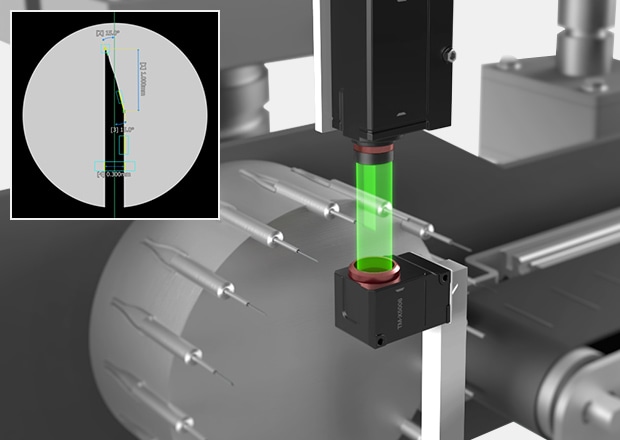

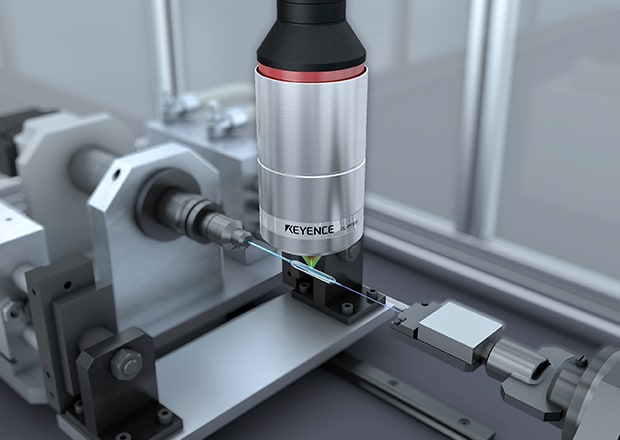

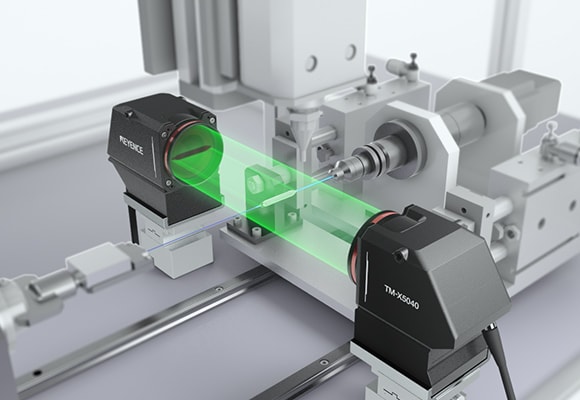

Injection Needle Tip Inspection

Accurately inspect needle tips inline. The TM-X5000 Series is a calibrated and traceable 2D measurement sensor that can be used for reliable inspection of medical components.

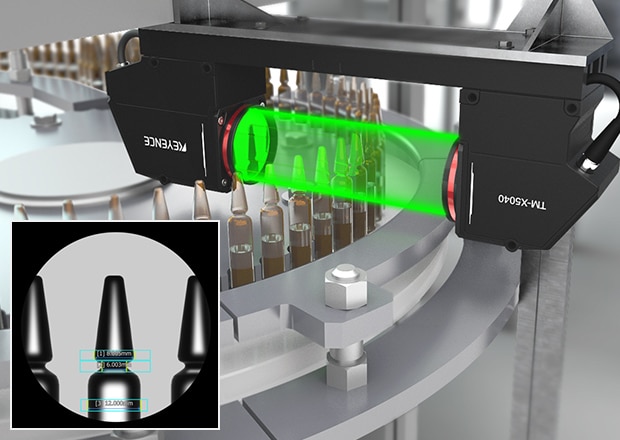

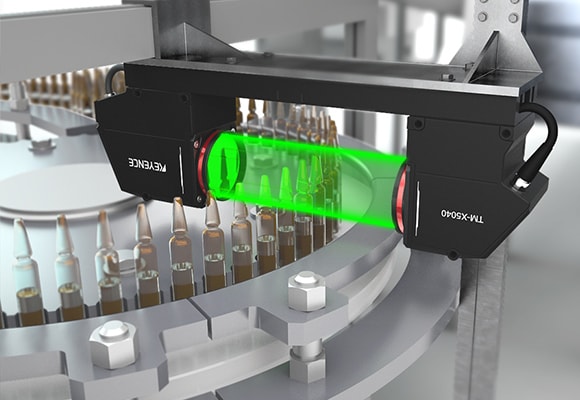

Ampoule and Vial Dimensional Inspection

Historically, it's been difficult to inspect dimensions of transparent objects, but the TM-X5000 Series makes it easy. The factory calibrated, backlit sensor greatly reduces the man-hours required to accurately measure transparent ampoules or vials.

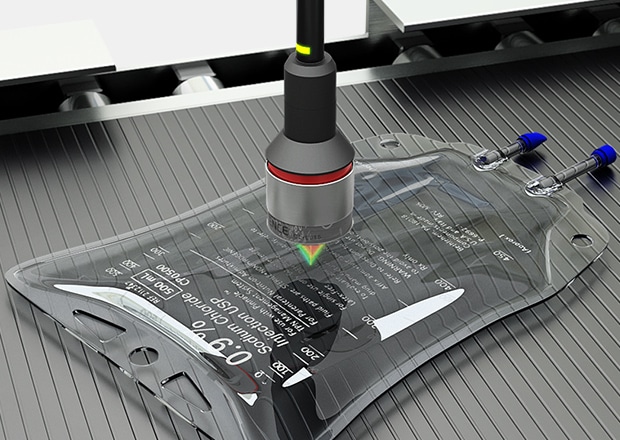

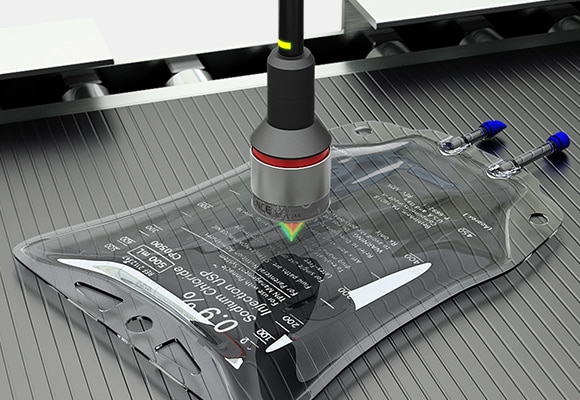

IV Bag Thickness Measurement

Bag thickness can be measured without contact. The CL-3000 Series receives reflections from the top and back surfaces of transparent targets simultaneously. The controller can calculate the distance between the two reflections to measure thickness. This system enables quick and reliable inline thickness inspection of transparent targets.

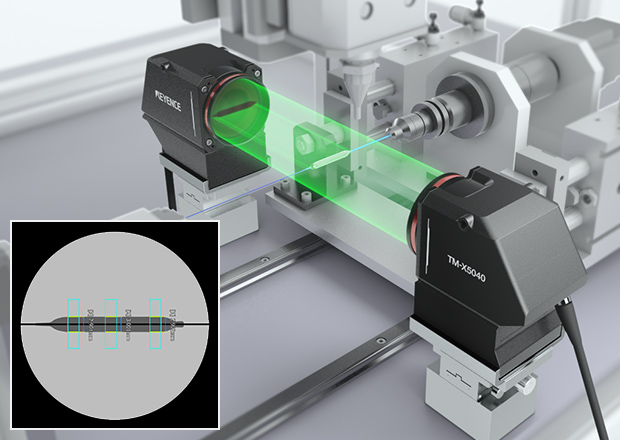

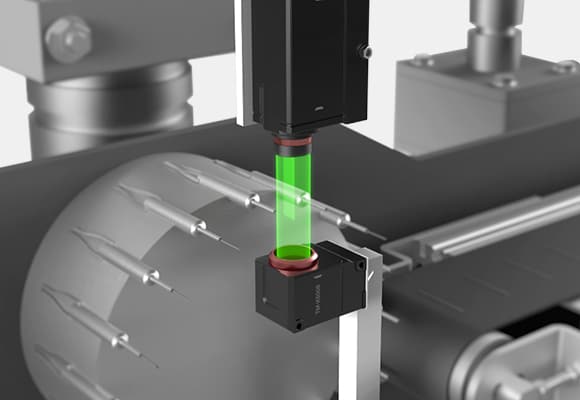

Balloon Shape and Maximum Diameter Measurement

Balloon shapes can be measured during inflation using the TM-X5000 Series. Previously, balloon shapes, such as outer diameter and angles, could only be measured offline using an optical comparator. The TM-X5000 Series offers high-speed measurement, providing access to real-time process data for testing or 100% inline inspection.

Thickness Measurement During Balloon Expansion

The thickness distribution of a balloon is important information to guarantee its strength. The CL-3000 Series measures the thickness of each part of the balloon when it is expanded. The non-contact method allows for highly accurate measurement without the risk of deforming or contaminating the target.

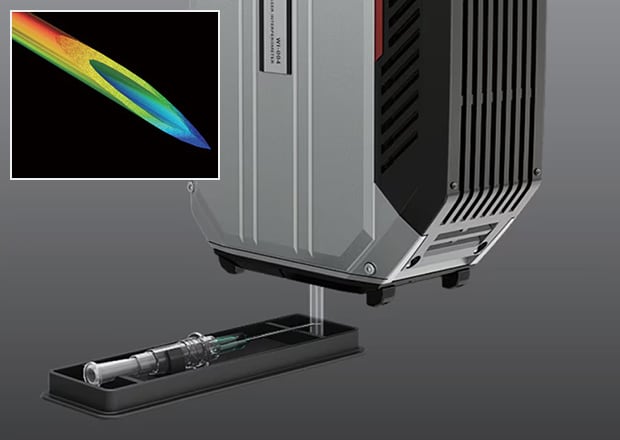

Surface Profile Measurement of Drip Infusion Needles

The WI-5000 Series uses a 3D white light interference method to enable measurements that are not affected by materials, colors, or blind spots. It can also perform batch measurements of surfaces up to 10 × 10 mm 0.39″ × 0.39″ in size, allowing for instantaneous, accurate measurements of the shapes of needle tips.

3D Snapshot Sensors for High-Precision Pharmaceutical Packaging Inspection

KEYENCE 3D Snapshot sensors deliver best-in-class 3D inline measurement for different pharmaceutical application needs. Manufacturers must check for proper sealing in packaging to avoid deterioration and alteration of active product ingredients. It's also important to ensure containers have no holes or cuts so that moisture or gases don't get inside the packaging, which could cause oxidation and product damage.

Our 3D laser snapshot sensors for medical industry solutions can capture a wide inspection area in a single shot with fast imaging in as little as 0.2 seconds, allowing production lines to carry out measurement and inspection tasks rapidly.

Discover more about this product.

Click here to book your demo.

Non-Contact Measurement Solutions with Snapshot Sensors in Medical Manufacturing

Manufacturing of medical products and supplies requires no physical contact measurements to retain the quality and integrity of products under measurement/inspection. Physical contact with many medical products can contaminate the targets, altering their characteristics. As a laser-based technology, 3D snapshot laser systems offer non-contact and precision measurement for dimension analysis, surface profiling, and many other applications.

Another benefit of using laser-based systems like 3D snapshot sensors is the ultra-high imaging speed. Plus, the 3D data captured helps provide the depth or height data required to accurately determine the dimensions, appearance, shape, and other features of packaging materials.

Medical Device and Syringe Inspection

The production of medical devices — such as needles, syringes, scalpels, and precision tweezers — often involves intricate designs that demand precision. Measurement sensors are often used for quality control purposes, such as measuring the dimensional accuracy of syringes, the shape and dimensions of injection needle tips, and the shape and dimensions of other devices.

These sensors ensure that the defective products get redirected on the production line long before they reach the packaging stage. Ampoule and vial dimensional inspection is also performed using sensors such as an optical micrometer.

Pill and Tablet Inspection

In pharmaceuticals, precision measurement sensors inspect several different aspects of pills and tablets—most notably their size, weight, and composition standards. These ensure the chemical uniformity and consistency of the product; laser sensors and machine vision are particularly useful in discerning misshaped, discolored, and inadequately coated pills and tablets.

Medical Equipment and Component Inspection

Medical equipment, ranging from mere tools to complex machines, also undergo thorough inspections. These inspections rely on precise measurement sensors, which ensure that all the equipment and components meet specified requirements and tolerances necessary for the proper functioning of said equipment.

We’re here to provide you with more details.

Reach out today!

Applications and Examples

Integrating Measurement Sensors into Medical and Pharmaceutical Inspection Processes

Integrating measurement sensors into the medical and pharmaceutical inspection process ensures that the products adhere to strict industry standards and are thus safe to use.

If you’re looking to integrate measurement sensors, KEYENCE has you covered. The TM-X5000 Series of thrubeam micrometer sensors is capable of providing fast and accurate measurements by capturing the silhouette of a target object, which is particularly useful in ampoule integrity verification and needle quality control.

Other sensors, such as the LK-G5000 Series, are often used to measure the uniform thickness of IV bags, while the LJ-X8000 Series often finds its use in pharmaceutical industries, where it inspects blister packaging for tears of missing tablets.

Boosting Production Efficiency with 3D Laser Snapshot Sensors in the Medical and Pharmaceutical Industry

Use laser snapshot sensors to enhance inspection efforts. Laser snapshot sensors for the medical and pharmaceutical industries, such as the LJ-S8000 Series, come with standard and proprietary functions that make measurement and inspection tasks faster, more accurate, and easier.

For example, our LJ-S Series is the first in the world to utilize a motor-driven scanning detection method. This design eliminates the need for an external lighting unit, lensing, a stage, or an encoder. With an imaging speed of 0.2 seconds and repeatability of 0.3 µm, the system can be installed in different medical and pharmaceutical lines for ultra-high-speed and ultra-high-accuracy inline inspections.

Streamline Your Inspection Process with KEYENCE

Interested in streamlining your medical and pharmaceutical inspection processes? Contact us today about how our 3D snapshot sensors can be utilized in your pharmaceutical packaging applications. From thrubeam micrometers to laser displacement sensors, we have the perfect solution for you!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity

![TM-X5000 Series Application Guide [Medical Devices]](/img/asset/AS_126582_L.jpg)