Measurement Sensors

Dimension Measurement

Displacement Measurement

Measurement Sensors for the Metal and Steel Industry

Efficiently converting iron ore into usable pieces of steel requires precision at each stage in the process. KEYENCE sensors provide measurement and inspection solutions to every facet of the steel industry—including red hot metal, cold rolling, and forming. Check out some of the solutions our sensors provide below.

The metal and steel industry has many sub-branches with different requirements for their respective manufacturing processes. For example, steel smelters need reliable temperature regulation, roller mills rely on infrared and laser displacement sensors, and steel component factories rely on ultrasonic sensors.

Get detailed information on our products by downloading our catalog.

View Catalog

Importance of Precision Measurements in the Metal and Steel Industry

Measuring temperature is a crucial part of metal and steel processing, as changes in temperature affect a metal’s mechanical properties. The metal and steel industry relies on other measurements too — such as length, weight, deflection, thickness, and width — all of which affect material properties and end-product quality.

We’re here to provide you with more details.

Reach out today!

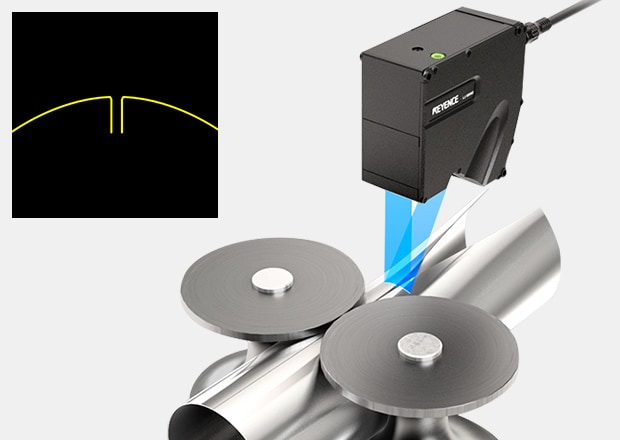

Pre-welding Groove Position

Tracking the position and height of each edge prior to welding helps to minimize defects that could negatively impact weld performance.

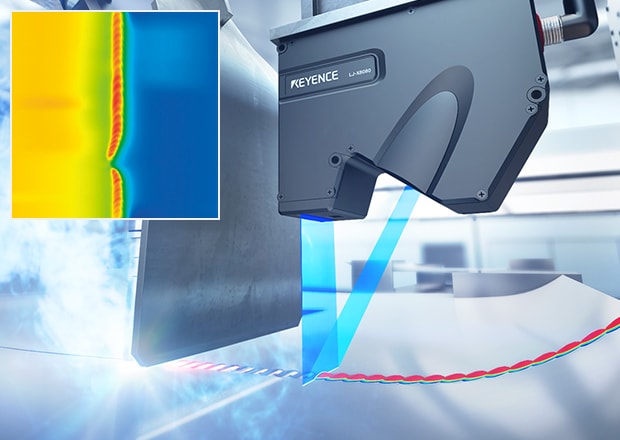

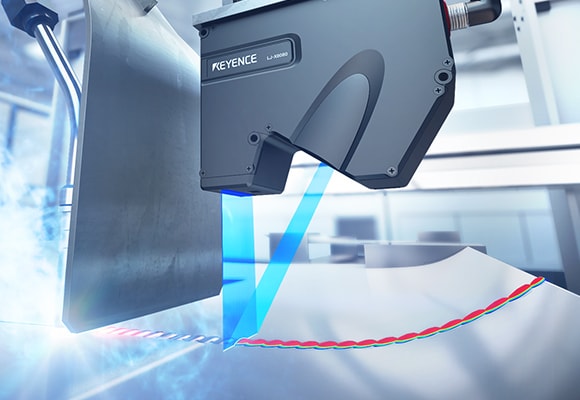

Weld Bead Inspection

Catch welding defects such as pits, melting, or spatter with 2D or 3D inspection using laser profilers. The LJ-X8000 Series is unaffected by the color of the weld, so it can reliably inspect any weld.

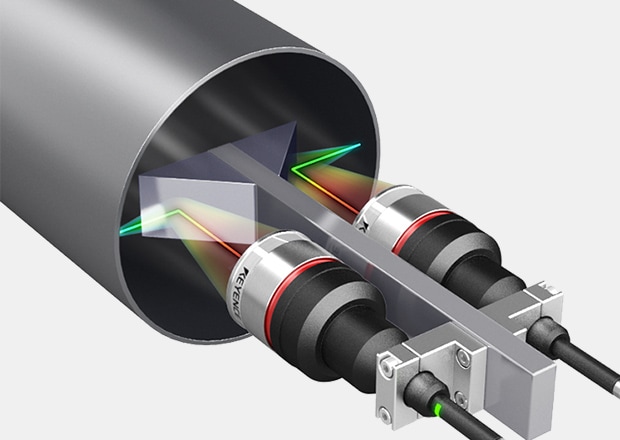

Roll Crown Inspection

Measure the top of rolls accurately, even those with mirrored surfaces. The confocal CL-3000 Series makes it easy to profile the top of a roll by recording displacement while scanning over the length.

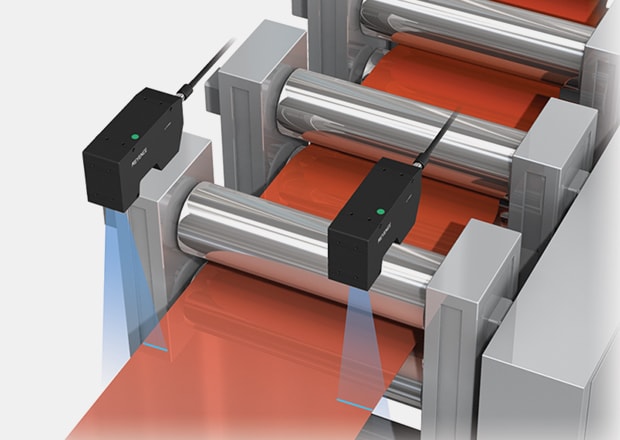

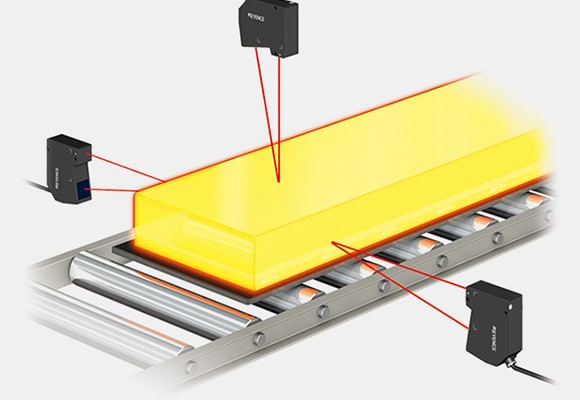

Cold Rolled Steel Sheet Thickness

The dedicated jig and alignment tools of the CL-3000 Series reduce setup time and improve accuracy of in-process thickness measurements. The non-contact thickness measurement method can ignore the influence of vibration for reliable inline inspection.

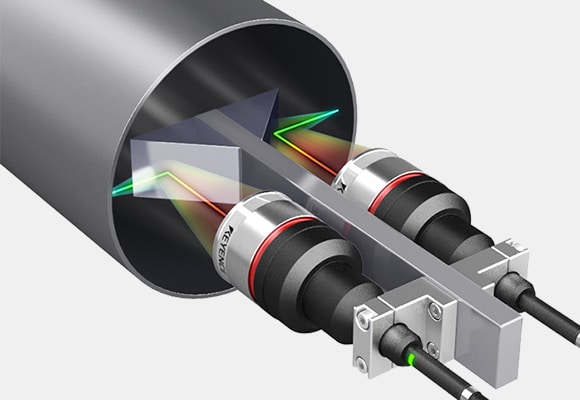

Steel Pipe Inner Diameter

Non-contact measurement of the inner diameter of a pipe is possible using compact sensors and right angle mirrors.

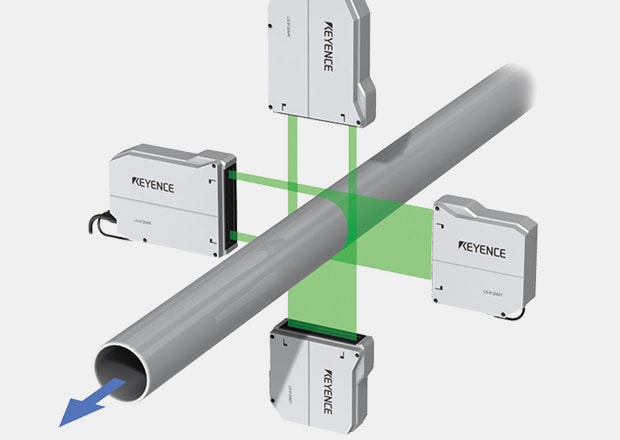

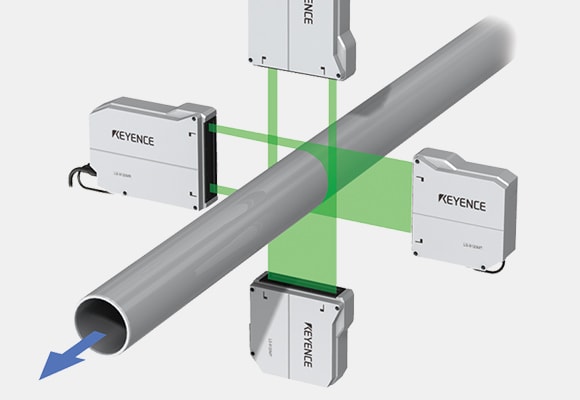

Steel Pipe Outer Diameter

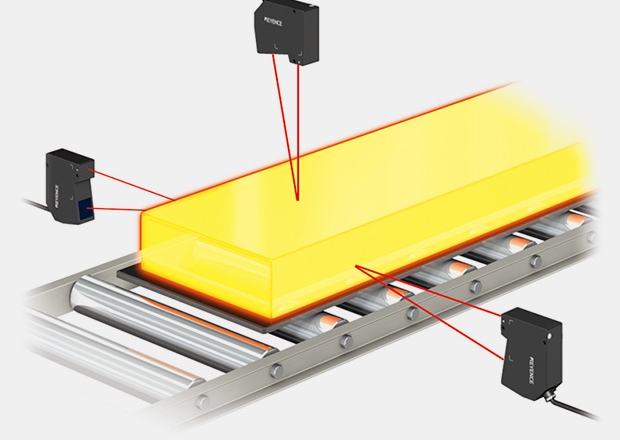

Inspect pipe outer diameter or ovality using single or multi-axis optical micrometers. The micrometer's static LED design maintains high accuracy over its lifespan with minimal maintenance required.

Slab Width and Shape Measurement

Red hot slabs can be measured during processing to minimize rework. The LK-G3000 Series’ long range enables you to place the sensor up to 1 m away from the heat source while maintaining accurate measurements.

Edge Position After Hot Rolling

Stably detect the edge position of red hot steel plates using a blue laser profiler. Easily detect defects without touching the sheet.

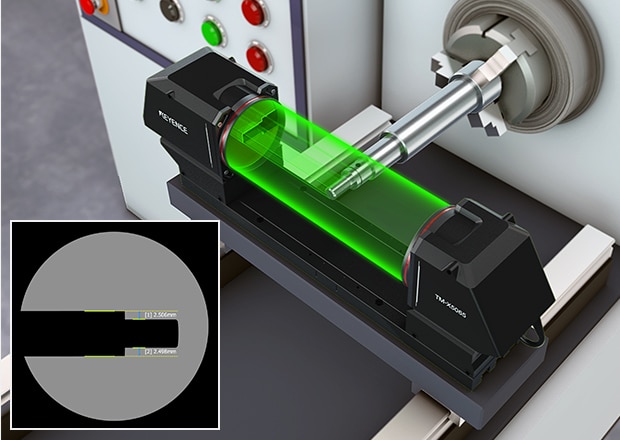

Measurement of H-Cut Shaft Dimensions

Measurement can be performed to determine whether the H-cut is in alignment with the shaft axis.

The distance to the surface of the shaft is measured when the H-cut is at its smallest on the top and bottom, and the difference between these two measurements is used to calculate alignment with the shaft.

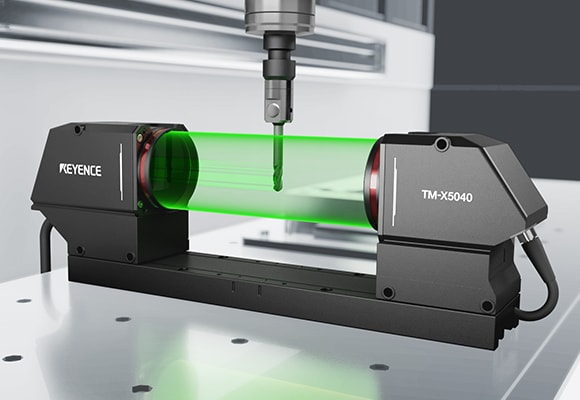

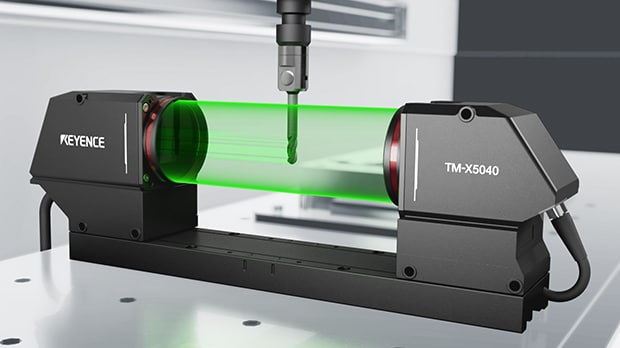

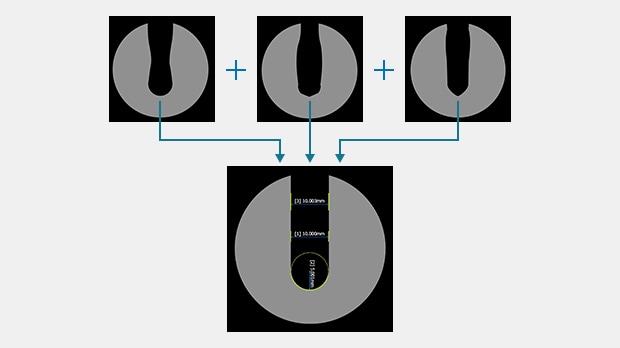

Outer and Tip Diameter Measurement of Ball End Mills

The image composition function combines multiple projected images into a single image. The resulting image can be inspected for outer diameter, tip diameter, tool length or chip inspection.

3D Snapshot Sensors for Metal and Steel Industry Applications

Laser snapshot sensors for the metal and steel industry are used in the processing and production of metallic materials. For example, 3D snapshot sensors are used to measure and inspect the metal sheets and slabs. This includes measuring different dimensions, checking the flatness, and identifying defects on the surface.

Discover more about this product.

Click here to book your demo.

Improving Quality Control with Snapshot Sensors in the Metal and Steel Industry

In the rolling mix process, as the ingot gets pressed down into thinner sheets of aluminum, it's important to verify the thickness of the sheet to determine the correct size. Using traditional measurement tools is not only unsafe and inefficient but can also lead to inaccurate measurement, affecting the quality of finished products.

3D laser snapshot sensors for metal and steel industry solutions like the KEYENCE LJ-S8000 Series are designed for use in various factory lines for metal sheet measurement and other applications.

Steel Processing and Manufacturing Inspection

Precise measurements at every stage of production are vital for steel manufacturing. When sorting the iron ore clumps delivered to the processing plant (smelter), the volume of each ore is calculated using 3D measurements of each profile.

This ore is then separated based on its volume for easier processing. During smelting, the ore is mixed with carbon and alloying elements to create steel, which is then shaped through rolling, forging, or extrusion. KEYENCE's LJ-X8000 Series sensors are typically used to measure slab width and warpage while measuring the workpiece's flatness.

The same applies to measuring the outer diameter of steel pipes, which can be measured while still glowing hot (does necessitate the use of a water jacket), along with sheet crown measurements and measuring the thickness of cold rolled steel sheets.

When cold rolled steel is made into various beams, the manufacturer relies on various types of laser profilers, such as KEYENCE’s LJ-X8000 Series 2D/3D laser profilers, to measure the physical dimensions of the rolled steel and ensure optimal properties and adherence to standardized measurements.

This level of control is necessary to ensure that the desired mechanical properties and surface finish are achieved.

Steel Component Quality Inspection

Measuring sensors—such as 2D and 3D laser displacement sensors and profilers—are often used to inspect the surface and structural integrity of steel components.

Why? Microcracks can become massive cracks once a steel beam is loaded with several tons of concrete. Fortunately, the aforementioned LJ-X8000 Series 2D/3D laser profilers are great for scanning various steel components for surface defects since their level of accuracy measures surface imperfections down to a single-digit µm range.

We’re here to provide you with more details.

Reach out today!

Types of Measurement Sensors for the Metal and Steel Industry

The metal and steel industry relies on several different sensor types to maintain the production process and ensure adequate quality control. For example, laser profilers (such as the LJ-X8000 Series) are ideal for measuring the width of the finished product, as well as the length and speed in the rolling mills.

Likewise, confocal laser sensors (such as CL-3000 Series) could be used to measure thickness of sheets and roll crowns.

Integrating Measurement Sensors into Steel Inspection Processes

Ultimately, the metal and steel industry relies on a wide range of different sensor types necessary to keep the production running. If you’re unsure about the implementation of sensing technology in your production process, don’t hesitate to ask KEYENCE—the industry leader’s team of experienced personnel will answer all the questions you might have about precise measurement sensors in the metal and steel industry.

Optimize Your Metal Production with LJ-S8000 Series Laser Snapshot Sensors

Many production lines optimize their metal and other product manufacturing with our LJ-S8000 Series of 3D snapshot laser sensors. These products can perform accurate 3D profile measurements to capture the full data of targets during manufacturing. Snapshot sensors' contactless measurements make them suitable for different applications where no physical contact is required.

With imaging in 0.2 seconds and repeatability of 0.3 µm, the LJ-S8000 Series is made for ultra-high-speed and accurate measurement and inspections for dimensions and appearance shape, and other product features.

Also, the one-of-its-kind motor-driven scanning detection mechanisms and internal lighting in the LJ-S8000 Series means zero need for lighting, a moving stage, or an encoder required in traditional systems.

For more information on how our laser snapshot sensors for the metal and steel industry can be used in your applications, contact us today. Our team of experts will guide you in choosing the perfect measurement sensors for your specific needs in the metal and steel industry.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Applications

Dimension Measurement

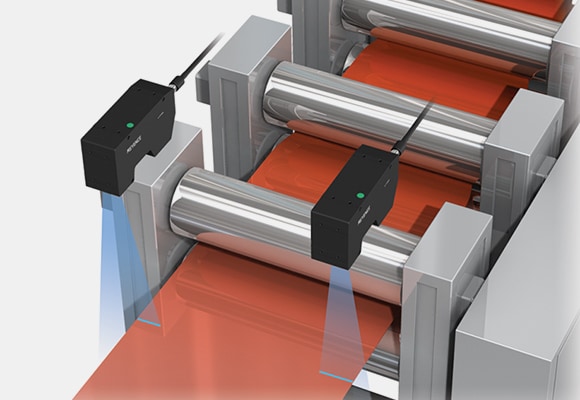

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity

![Expert Solutions [Steel Processing]](/img/asset/AS_55842_L.jpg)