Measurement Sensors

Dimension Measurement

Displacement Measurement

Measurement Sensors for the Electric Vehicle Industry

In the increasingly competitive world of e-mobility, efficient production of high-quality components for electric vehicles (EVs) and their batteries is critical. KEYENCE sensors are playing a large role in helping suppliers and manufacturers achieve their goals for process improvement and component reliability. Below we explore how KEYENCE's measurement sensors are essential tools for the electronics industry in meeting these new demands.

Thanks to the massive jumps in innovation and high-tech solutions, the EV — once an object of science fiction — has become a reality for many. The electric vehicle industry is evolving at an unprecedented rate, and it uses measurement sensors to ensure the quality and reliability of its products.

Get detailed information on our products by downloading our catalog.

View Catalog

Importance of Precision Measurements in the Electric Vehicle Industry

As with the rest of the automotive industry, precision in the electric vehicle industry is not a matter of quality alone. It’s also a matter of vehicle performance and passenger safety. With more and more EVs cruising through urban areas, ensuring the precision and accuracy of every component — from batteries to ECUs — has become crucial. This is especially true with the rise of self-driving cars, which rely on advanced sensors and complex vision systems.

Precision measurement results in precision manufacturing, which in turn guarantees that the EVs meet the strict, rigorous standards of the automotive industry and perform efficiently and reliably.

We’re here to provide you with more details.

Reach out today!

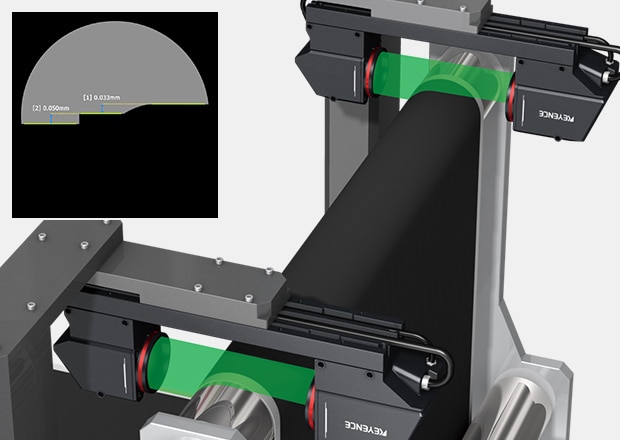

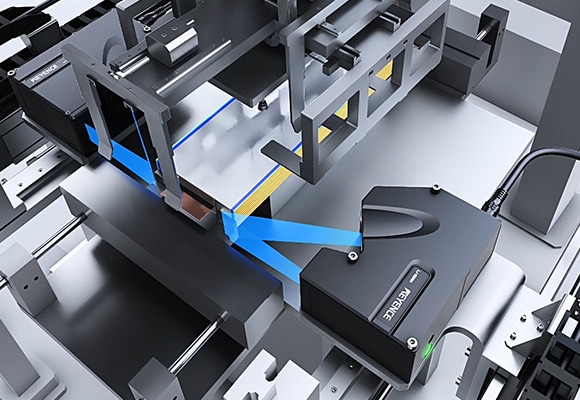

Thickness Measurement after Roll Pressing

The TM-X5000 Series projects the 2D shape of a web's edge to measure thickness with high accuracy. By capturing the surrounding area, the TM Series can account for web decentering or roll runout to correctly measure the material thickness regardless of surface condition.

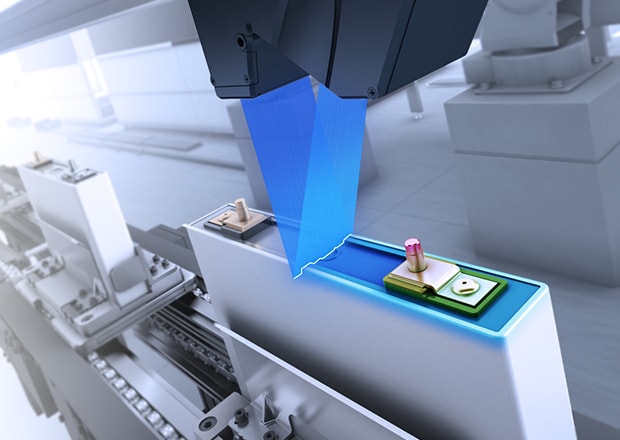

Laser Welding Bead Shape Inspection

Detect chipping or dents in laser welded beads using 3D laser profilers. The measurement is unaffected by color or gloss of the weld, making inspection results stable through glare or bead shape variation.

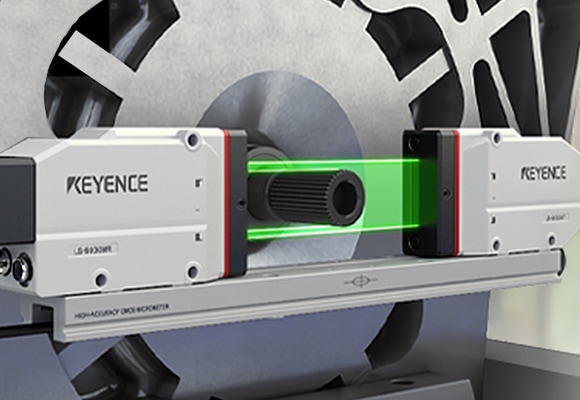

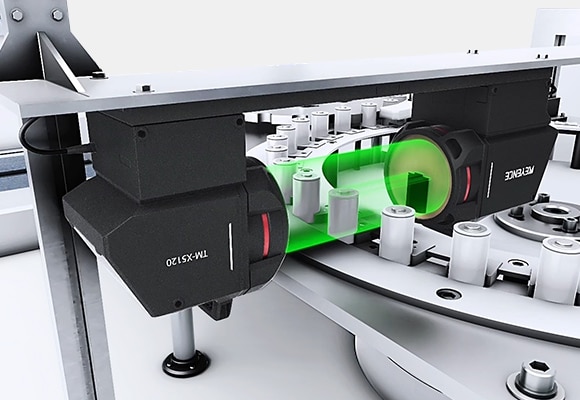

Rotor Runout Measurement

Measure core eccentricity without touching the part. The high-speed sampling of the LS-9000 Series enables accurate measurement of the core position and diameter during rotation and eliminates operator error.

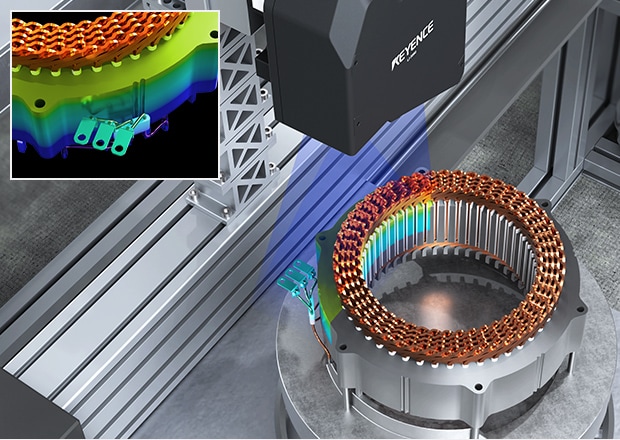

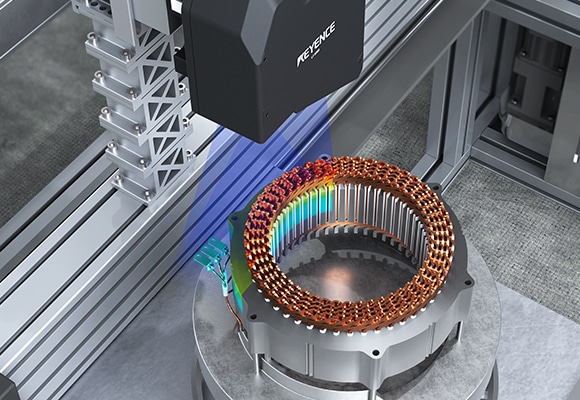

3-Phase Stator Terminal Height and Position Measurement

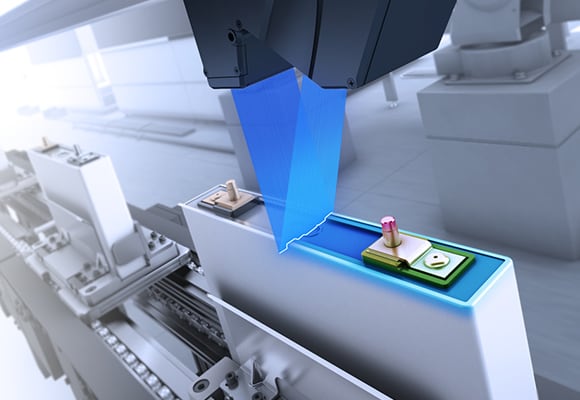

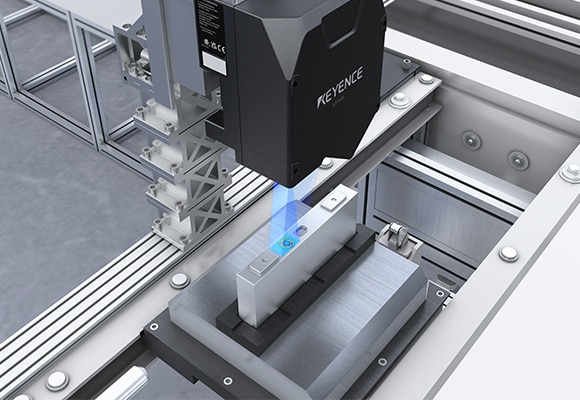

The LJ-S8000 Series 3D Laser Snapshot Sensor uses a line laser to scan the target surface, inspecting both the height and position of stator terminals at the same time. In addition, the LJ-S8000 Series’ built-in scanner eliminates the need for auxiliary parts, such as stages and encoders, therefore eliminating the time otherwise needed for specifying and implementing those additional devices. Inspections are possible simply by attaching the LJ-S8000 Series to the equipment.

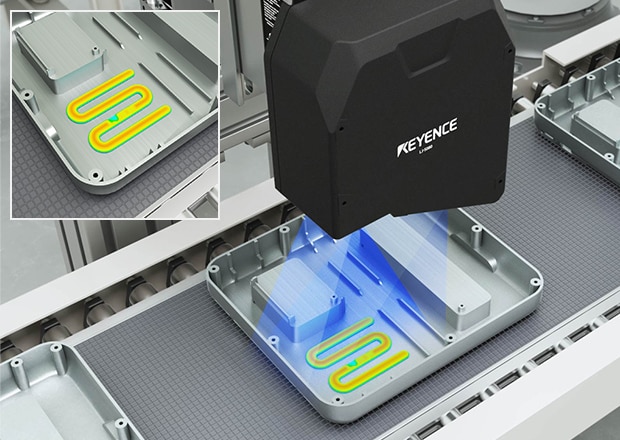

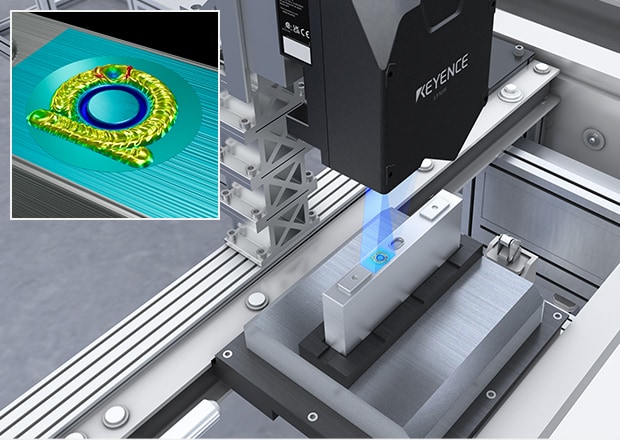

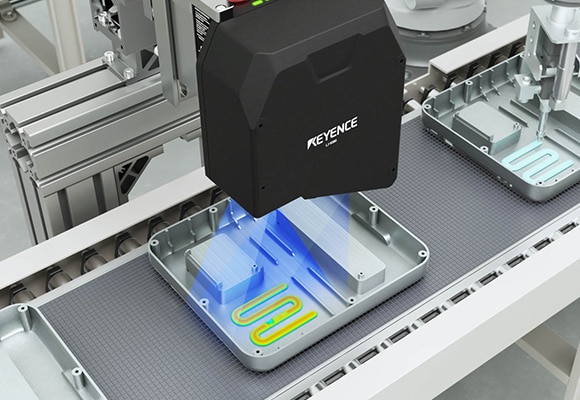

Heat Dissipation Material (Gap Filler) Width, Height, and Volume Inspection

The LJ-S8000 Series 3D Laser Snapshot Sensor can inspect the heat dissipation material applied by a dispenser. Although simultaneous inspection of width and height is difficult with grayscale images from conventional vision sensors, the LJ-S8000 Series scans the target surface shape to obtain height information that can be used for inspecting height, width, and volume of heat dissipation materials. Since the scanner is built into the sensor head itself, no additional resources or time are required for auxiliary parts, such as stages and encoders. Inline inspections with the LJ-S8000 Series are as simple as attaching the device to existing equipment.

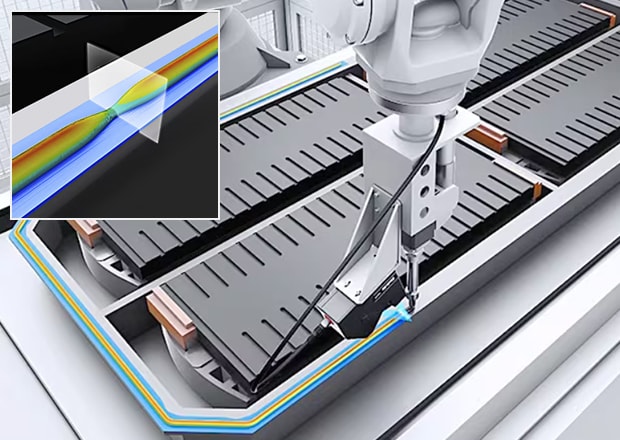

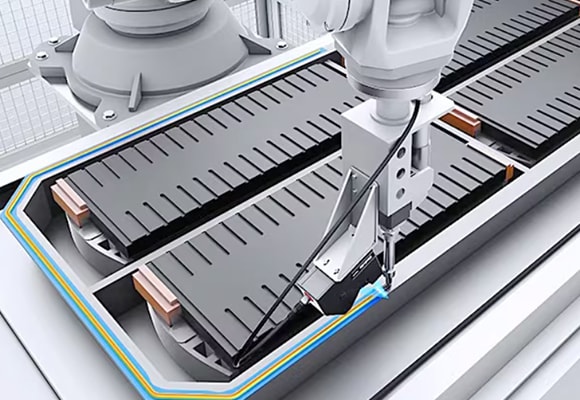

FIPG Coating Inspection for Battery Case

Since the battery on an EV is situated under the floor, the battery case must be airtight to prevent water and foreign matter from entering it. The LJ-X8000 Series features a wide dynamic range with high sensitivity, allowing for stable and reliable inspections.

Inlet Weld Appearance Inspection

Appearance inspections of targets with variations in surface color or gloss, such as welding beads, are not stable with conventional grayscale images. With 3D appearance inspection, however, height measurement data makes it possible to detect uneven surfaces without being affected by the target surface condition. In addition, the LJ-S8000 Series 3D Laser Snapshot Sensor’s built-in scanner eliminates the need for auxiliary parts such as stages and encoders, and therefore also eliminates the time otherwise needed for specifying and implementing those additional devices. Inspections are possible simply by attaching the LJ-S8000 Series to the equipment.

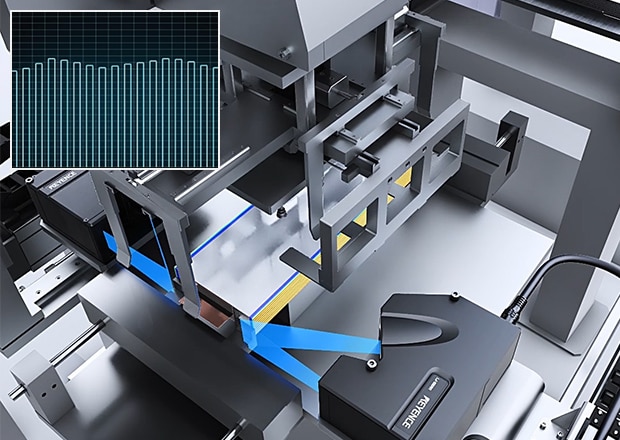

Electrode Thickness after Coating

Measure electrode thickness. To ensure proper coating application, the thickness must be determined accurately. This is achieved by calculating the thickness of the electrode and the foil itself after coating.

The special jig assists in properly aligning the sensor heads, which reduces measurement error and makes it easy to acquire high accuracy measurements.

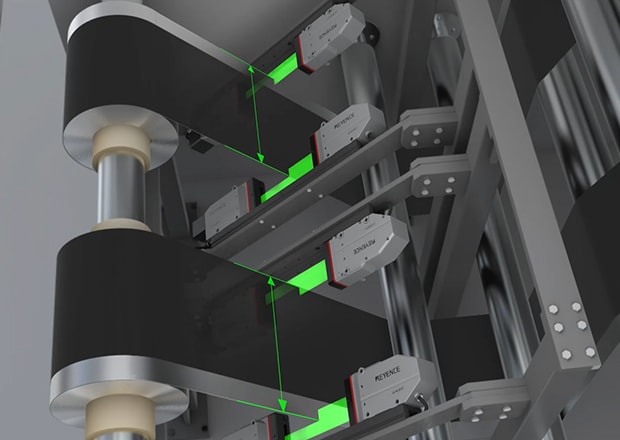

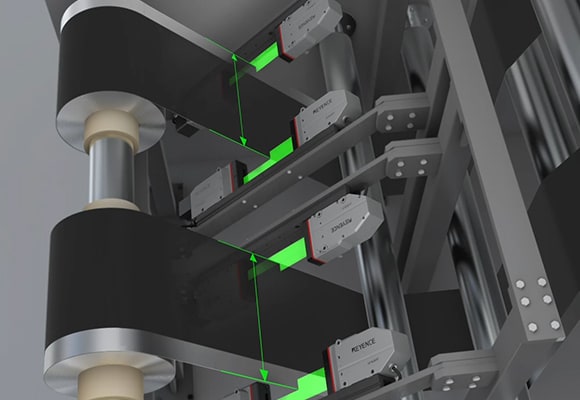

Electrode Width Measurement

Inline width measurement of battery parts cut by slitting machines. The dimensions can be managed without being affected by ambient light or electrode tilting during conveyance.

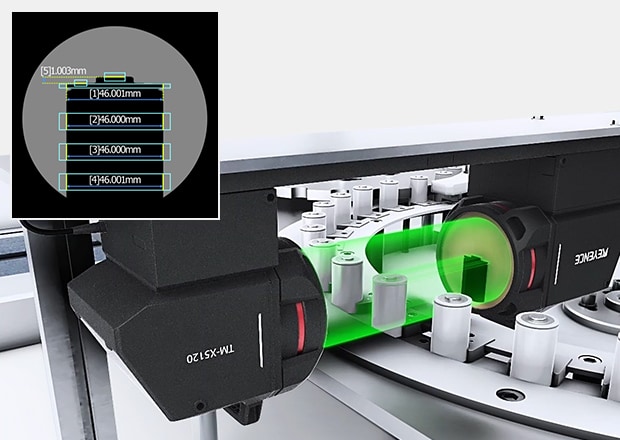

Outer Can Crimping Inspection (Cylindrical)

The outer diameter is instantly measured at multiple locations after the cover is staked and bonded to the can. High-speed exposure and a large depth of field of up to ±20 mm ±0.79″ allows for stable inline inspection.

Electrode Thickness Measurement Inside a Vacuum Chamber (Vacuum Deposition)

The anode of lithium metal batteries, which are a type of solid-state battery, is formed inside a vacuum chamber. The vacuum- compatible CL-S015 can provide vacuum evaporation conditions and improve yield rates by measuring thickness inside the chamber.

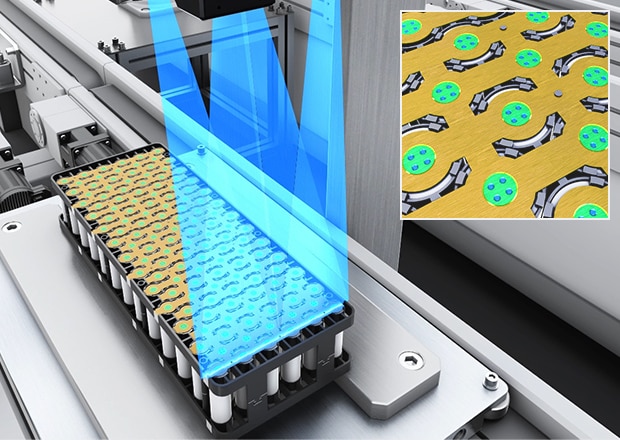

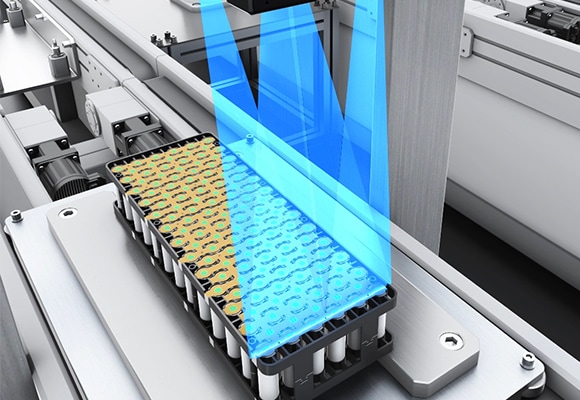

Laminated Electrodes Misalignment Inspection (Pouch)

The presence of lamination misalignment is checked after the lamination process. The LJ-X8000 Series can obtain profiles at a minimum pitch of 2.5 µm 0.000098″, ensuring that every electrode profile is accurately measured even during conveyance.

Measurement of Bus Bar Height and Position (Cylindrical)

The height inspection of bus bars before welding and the inspection of XY positions after welding can be performed with a single system. Although the inspection of X and Y positions can be performed by conventional vision systems, with the 3D data of the LJ-X8000 Series, XY position as well as Z-height data can be inspected simultaneously.

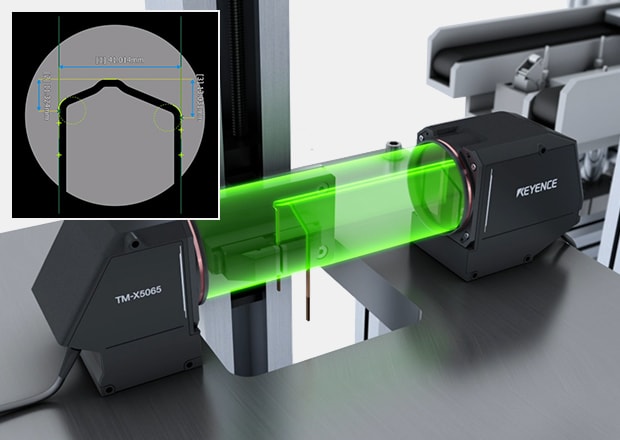

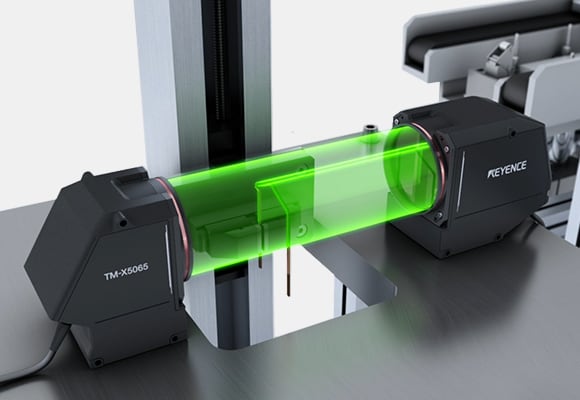

Measurement of Hairpin Vertex Height and Shoulder Width

The TM-X5065 measures the hairpin profile after forming.

The TM-X5000 Series can measure widths, angles, and height differences simultaneously, preventing improper assembly of the stator and improving production yield.

EV Battery Component and Assembly Inspection

Batteries are at the very heart of the EV, and a large chunk of research and development in the electric vehicle industry is dedicated to battery development. Batteries are manufactured in stages, implying that the individual batteries are aligned and packed into designated cells, they’re welded together, and the electrodes are precisely positioned to ensure the correct polarity of further assembly.

All of these operations demand dimensional accuracy and precise measurement using laser profilers or displacement sensors, such as KEYENCE’s LJ-X8000 Series laser profiler and CL-3000 Series laser displacement sensor. This allows the battery assembling robots to position the batteries correctly and weld them together properly. Once assembled, these batteries are spent for subsequent visual and electrical inspections.

EV Motor Component Inspection

Any misalignment in the electric motor’s windings affects their uniformity, mechanical balance, and electrical performance, which ultimately leads to other performance issues and increased wear over time.

To minimize the chance of that happening, the EV industry relies on the aforementioned sensors to analyze the uniformity of the windings and inspect various other aspects that comprise the electric motor. This includes the motor’s shaft, stators, rotors, and housing.

EV ECU Assembly Inspection

The electric control unit is the brain of many vehicles, not just electric ones. They control engine operation, fuel consumption, and several other factors. Since they’re mostly electronics, ECUs are assembled onto circuit boards, with connectors and various other components checked for defects and proper assembly, which ultimately results in a more reliable operation.

Types of Measurement Sensors for the Electric Vehicle Industry

Making an electric vehicle is rather complex, and the majority of the process is mostly done by robots. These robots often rely on complex vision systems comprised of several seeing sensors and cameras to guide them and enhance their precision capabilities.

Machine vision systems, such as KEYENCE’s IV3 Series, paired with other 2D/3D profilers and measurement sensors, ensure that the entire production process goes as smoothly as possible without having to sacrifice the aforementioned reliability and safety of the end product.

Integrating Measurement Sensors Into Electric Vehicle Inspection Processes

Integrating measurement sensors into electric vehicle inspection helps the electric vehicle industry remain compliant with stringent industry standards and various laws and regulations. Ultimately, these integrations effectively raise the quality of the end product while also minimizing downtime and addressing production errors in a much more precise and reliable way.

Interested in improving the production process of your electric vehicle assembly? Contact KEYENCE to learn more about our advanced machine vision systems and measurement sensors, designed specifically for the electric vehicle industry.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity

![Industry Trends New Measurement Solutions [Automotive Electronic Components/Automobiles]](/img/asset/AS_52282_L.jpg)