Envelope Requirement

The envelope requirement means that the maximum (or minimum) allowable size for a part must be within the same range (or out of the same range) as the maximum size (or minimum size). It specifies that the surface of a single feature of size (a cylindrical surface or a feature established by two parallel opposite plane surfaces) should not violate the imaginary envelope of perfect (geometrically ideal) form at the maximum material size.

Feature of Size

“Feature of size” is the geometric shape defined by size dimensions such as length and angle. Examples of feature of size include cylindrical and spherical forms as well as two opposing planes. Since the feature is defined by size dimensions, the overall size changes along with the dimensions.

The target parts for geometric tolerance depend on the position where the indication line is drawn. In the following drawings, for example, based on where the indication lines are, the center lines and generatrices for straightness in the same shape may or may not indicate a feature of size.

- a

- Target part for geometric tolerance

- a

- Target part for geometric tolerance

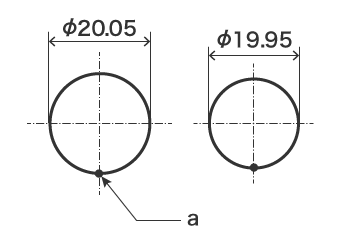

Maximum Material Size (MMS)

This determines a feature’s maximum material condition (MMC). The maximum material condition is a state of the considered extracted feature, where the feature of size is at that limit of size where the material of the feature is at its maximum everywhere, e.g. minimum hole diameter and maximum shaft diameter. In short, the maximum material size is what defines the maximum material condition of a feature.

- Maximum material size (MMS) of a shaft (convex)

- Φ20.1

- Maximum material size (MMS) of a shaft (concave)

- Φ19.9

Envelope of Perfect Form

This means the perfect zone made in the maximum material condition for the size tolerance indicated in a drawing, and the target must exist inside the zone of the maximum material size.

- a

- Φ5.0 (max. material size)

- a

- Φ5.0 (max. material size)

What Is ?

To apply the envelope requirement to a dimension, you write after the size tolerance. “E” stands for “envelope,” and this symbol indicates that if a part conforming to size tolerance is within the envelope of perfect form, which has the maximum material size, the part passes this requirement. If not, the part has failed to fulfill the requirement.