Dimension Inspection of Processed Parts

- CASE

- Metal Processing

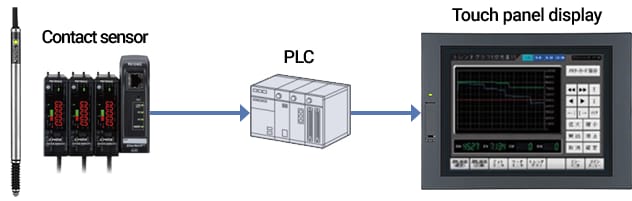

Record data for metal parts after processing.

Connect to IoT

Traceability is mandatory for metal parts used for automobiles. Consequently, the processing data must be as accurate as possible. Digital data does not suffer precision degradation and allows for accurate records of all parts.

Related productGT2 Series

The following data can be obtained.

| Process data | Height of target, drill rotation speed, oil pressure/quantity, alarm output, and control signal |

|---|---|

| Diagnosis service data | Self-diagnosis status of the measurement system (errors, etc.) |

Related pages

- Numerical Management of Press Behavior

- Centralized Management of Processing Conditions

- Management of Solidification Temperatures

- Height Management of Assembled Targets

- Checking Mold Conditions

- Inspection of Metal Processing

- Level Detection of Plating Bath Solution

- Laser Marking on Metal Parts

- Measurement of Drill Bit Outer Diameter

- Recognition of Marked Characters

- Coolant Flow Management