Height Management of Assembled Targets

- CASE

- Metal Processing

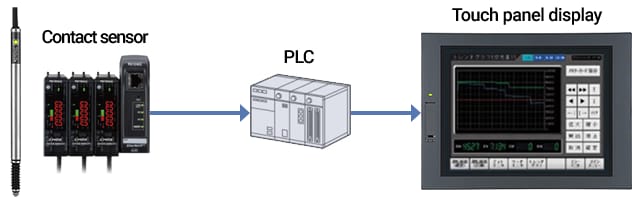

Check the differences in the height of assembled targets and record the result for each product type.

Connect to IoT

When there are many product types and pieces of equipment, setting each item manually is troublesome and may cause errors. This trouble and these errors can be eliminated with a system that uses a PLC to differentiate product types based on the information read from bar codes or other media and automatically switches differentiation and recording conditions.

If a sensor breaks and has to be replaced, the use of setting data stored in the PLC saves time during recovery.

Related productGT2 Series

The following data can be obtained.

| Process data | Height of target, number of shots, alarm output, and control signal |

|---|---|

| Diagnosis service data | Self-diagnosis status of the measurement system (errors, etc.) |

Related pages

- Numerical Management of Press Behavior

- Centralized Management of Processing Conditions

- Management of Solidification Temperatures

- Checking Mold Conditions

- Inspection of Metal Processing

- Level Detection of Plating Bath Solution

- Dimension Inspection of Processed Parts

- Laser Marking on Metal Parts

- Measurement of Drill Bit Outer Diameter

- Recognition of Marked Characters

- Coolant Flow Management