Laser Marking on Metal Parts

- CASE

- Metal Processing

Mark 2D codes or characters showing lot numbers and dates to achieve traceability.

Connect to IoT

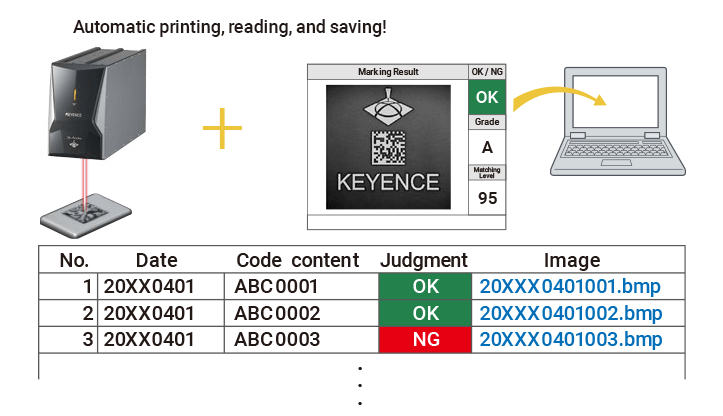

Some laser markers are multifunctional so that they can not only mark products but also acquire data or images of marking with a built-in camera for history recording or output.

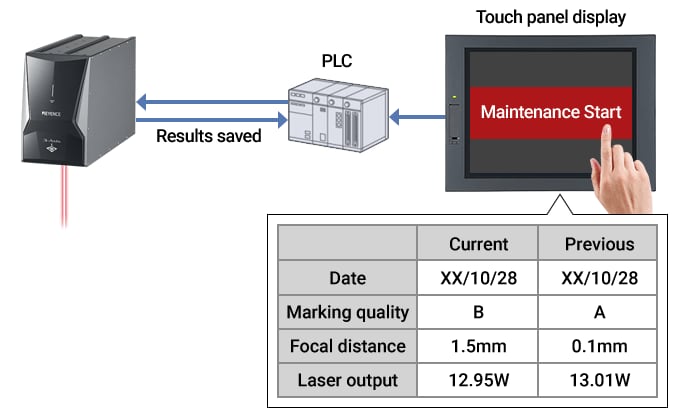

The volume of information that needs to be collected to achieve stable operation is increasing due to the growth of IoT. The importance of acquiring data and selecting equipment with management functionality is ever-increasing.

Related productMD-X Series

The MD-X Series is characterized by its process improving system based on ActiveX.

ActiveX technology allows for direct control of the laser marker using other software (such as Excel).

| Automatic history management of marking details | The MD-X Series has a built-in camera in its head. When marking is complete, the history can be recorded automatically, including the date, marked data, OK/NG, grade, and marking image. In case a problem occurs, you can solve it quickly by reviewing the previous results. |

|---|---|

| Visualization of laser marker status | The work required for predictive maintenance of the laser marker can be completed with a single click. The laser's power output, marking quality, and distance between targets can be measured, and all of this data can be output. It is also possible to show the change in inspection results as a graph, which enables visual checking of the condition of or changes in the facility. |

Related pages

- Numerical Management of Press Behavior

- Centralized Management of Processing Conditions

- Management of Solidification Temperatures

- Height Management of Assembled Targets

- Checking Mold Conditions

- Inspection of Metal Processing

- Level Detection of Plating Bath Solution

- Dimension Inspection of Processed Parts

- Measurement of Drill Bit Outer Diameter

- Recognition of Marked Characters

- Coolant Flow Management