Inspection of Metal Processing

- CASE

- Metal Processing

Record data for metal parts after processing.

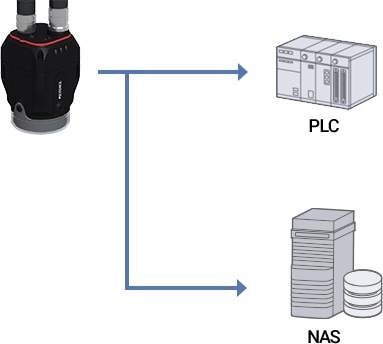

Connect to IoT

The part tags of processed parts can be linked to the actual image data for data storage. When a customer requests manufacturing data, the process can be traced back, which increases their confidence in the product.

Related productIV Series

The following data can be obtained.

| Process data | Completeness of metal processing, degree of similarity, judgment output (High, Low, Go), and alarm output |

|---|---|

| Diagnosis service data | Self-diagnosis status of the measurement system (errors, etc.) |

Related pages

- Numerical Management of Press Behavior

- Centralized Management of Processing Conditions

- Management of Solidification Temperatures

- Height Management of Assembled Targets

- Checking Mold Conditions

- Level Detection of Plating Bath Solution

- Dimension Inspection of Processed Parts

- Laser Marking on Metal Parts

- Measurement of Drill Bit Outer Diameter

- Recognition of Marked Characters

- Coolant Flow Management