Numerical Management of Press BehaviorIL Series

Manage the stroke amount and speed of a press as numerical data and use them for analysis or improvement of equipment.

The quality of metal processed products is greatly affected by temperature, pressure and other conditions of manufacturing processes. Importance is placed on the provision of optimum conditions as well as on process management. The introduction of IoT is an extremely important technology in the metal processing industry because of its ability to manage every piece of data on manufacturing sites.

Manage the stroke amount and speed of a press as numerical data and use them for analysis or improvement of equipment.

Quickly set the optimum conditions during mold replacement.

Record and manage height, processing time, and other data for each product type to save time during changeovers.

Keep a record of processing.

Measure flatness from the values measured at multiple points and record the result.

Mark 2D codes or characters expressing lot numbers and dates to ensure traceability.

Monitor a drill bit continuously for inclination or wear.

Monitor flow tendency and visualize amount used.

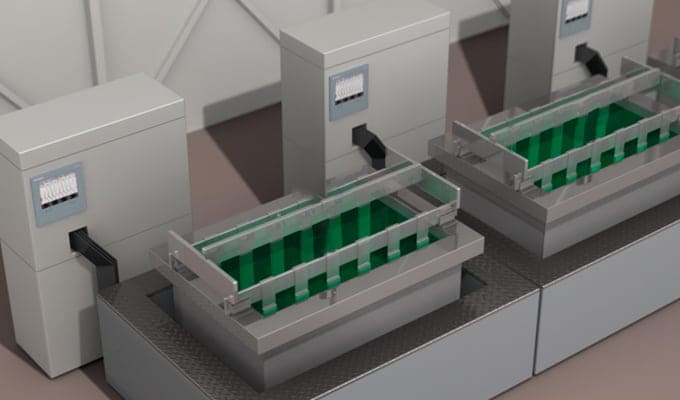

Monitor the solution level in a plating bath continuously.

Check the temperature of each part after hardening and compare/analyze the difference from the expected value.

Manage the assembly work of all products based on different criteria for each product type.

Acquire traceability information for each product type and manage the product information for each part.