Checking Welding Torch Position

- CASE

- Automotive Body Assembly

Optimize the position of the torch tip according to the product type and welding conditions.

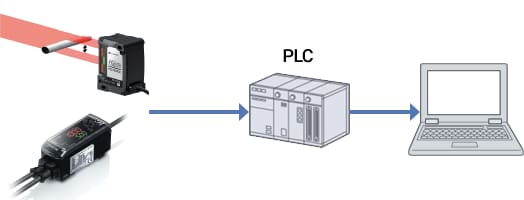

Connect to IoT

The best spot to apply the torch varies depending on the shape of the target, the welding current, and other conditions.

Managing these measured values on the same platform as the robot data makes it easier to implement improvements to the program.

Related productIG Series

The following data can be obtained.

| Process data | Torch position, judgment output (High, Low, Go), alarm output, and control signal |

|---|---|

| Diagnosis service data | Self-diagnosis status of the measurement system (errors, etc.) |

Related pages

- Numerical Management of Press Behavior

- Predictive Maintenance Through Management of Press Hydraulic Pressure

- Differentiation of Rotor Types

- Stem Oil Seal

- Front/Back and Presence/Absence Detection of Weld Nuts

- Checking for Different Components during PCB Assembly

- Continuous Measurement of Chain Elongation

- Batch Reading of Individual Identification Codes on an EV Battery Pack

- Inspection of Urethane Foam Applied on Glass

- Body Assembly Accuracy Inspection and Data Collection