Numerical Management of Press BehaviorIL Series

Use numerical analysis to manage the stroke distance and speed of a press and use it for improvements.

It is said that a car consists of over 30,000 parts, including tiny bolts. The number of parts is still increasing due to the shift to global production and multifunctionalization of products. As demands for higher efficiency and competitive power increase, including process optimization and cost reduction, the introduction of IoT is becoming essential.

Use numerical analysis to manage the stroke distance and speed of a press and use it for improvements.

Collect the data of the number of shots and the status of hydraulic pressure and use it for predictive maintenance.

Implement traceability management of all cars by checking which battery is used in which car body.

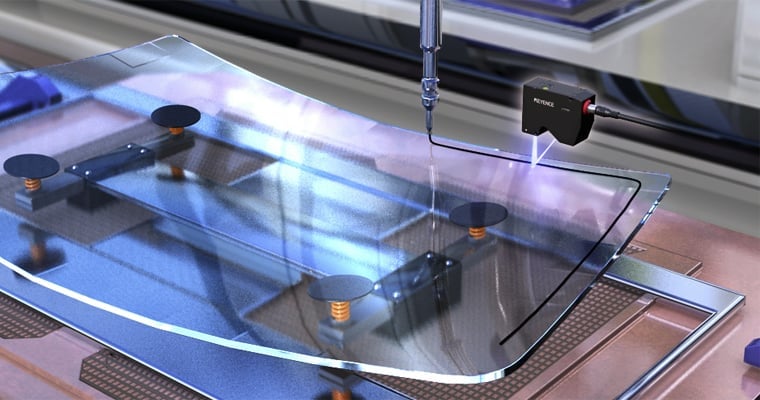

Measure discontinuities, height, width, cross sectional area, and position of urethane foam applied on a glass plate to prevent the outflow of defective products.

Measure and record the position of the torch tip to perform comparative management with programmed values.

Store the condition of the nuts, the wear on the welding tip, and the number of welding operations together.

Collect data for each assembly type to use for analysis or improvement of equipment.

Perform continuous judgment of the status of the conveyor chain for hanging body parts to prevent damage caused by wear.

Store the result of the type judgment of assembly parts together with the time, part number and other information.

Keep a record of the assembly's accuracy for critical components.

Keep a record of the status of the components on a PCB.