Measurement Sensors

Dimension Measurement

Displacement Measurement

Lead Frame Inspection and Measurement

A lead frame is a thin metal layer used in the semiconductor industry for device assembly processes. It's most commonly used as part of broader integrated circuitry to connect integrated circuits to their boards and motherboards. In other words, it bridges the tiny etched electrical terminals of a CPU, for example, with its contacts on the motherboard.

Lead frames are used to create most kinds of integrated circuit packaging. For example, a silicon chip is placed on a lead frame, which is then bonded to the chip and covered with plastic. This leaves only the end contacts of the IC exposed.

With the ongoing miniaturization of electronics and the ICs entering the nanometer range, the need for accurate and precise inspection and measurement methods grows.

Get detailed information on our products by downloading our catalog.

View Catalog![Automated Measurement and Inspection Examples [Semiconductors]](/img/asset/AS_119841_L.jpg)

Principles of Lead Frame Inspection

Lead frames are typically stamped or photo-etched on strips of metal. Due to their miniature nature, traditional measurement and inspection methods are time consuming, susceptible to error or simply impossible due to physical constrictions.

Still, detecting faulty lead frames as early in the manufacturing process as possible is extremely important, as it prevents the waste of valuable production resources and unveils any potential issues with the production process.

Advanced Technologies in Lead Frame Measurement

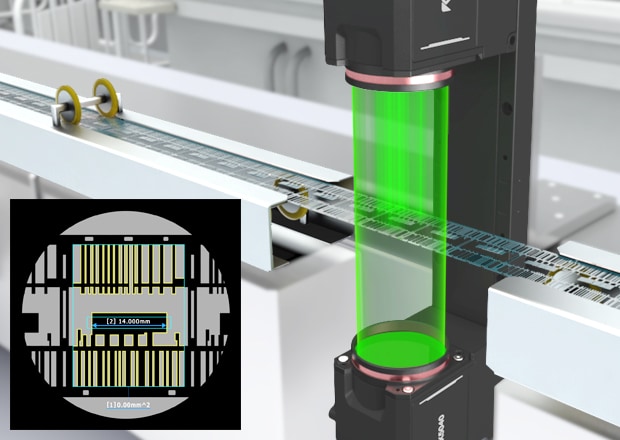

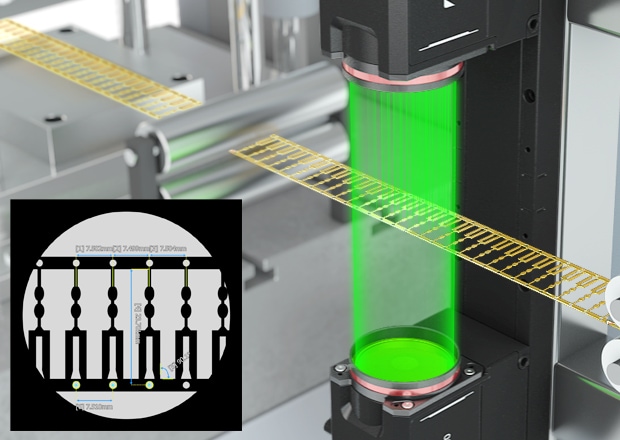

KEYENCE TM-X5000 Series Optical Micrometers perform multiple inspections simultaneously, enabling reliable defect detection on complex lead frames.

Fortunately, laser profilers and inline optical micrometers can scan lead frames to detect any surface defects such as scratches or strains. However, given their operational principles, these devices can also detect bent pins, missing components, cracked solder, and incorrect component orientation.

These inspection systems are capable of identifying any deviations from specifications, moderating the production process, and generating a detailed report regarding any defect they find in a specific lead frame. This reduces the potential for human error while enhancing the reliability of the inspection process.

Get detailed information on our products by downloading our catalog.

View Catalog

Critical Parameters to Monitor During Lead Frame Inspection

The most important parameters associated with lead frame inspection are alignment, flatness, and surface quality of the lead frame, all of which can be derived from height measurements provided by KEYENCE's laser profilers.

This allows the quality assurance automation to derive other important information, such as width, length, thickness, and spacing. These are crucial parameters that ensure that the lead frame fits correctly within the IC package.

Benefits of Automated Inspection Systems for Lead Frames

Automated inspection systems offer numerous benefits for lead frame inspection, including enhanced accuracy, efficiency, and consistency. By automating the inspection process, semiconductor manufacturers can achieve higher throughputs while reducing quality issues.

Accordingly, one of the primary benefits of an automated system is the ability to perform quality control at high speeds while still maintaining high precision. These systems can quickly scan lead frames to identify defects and deviations in real time to provide consistent and repeatable results.

Integrating Lead Frame Inspection Into Manufacturing Lines

KEYENCE’s TM-X5000 Series performing inline lead frame measurements.

Most laser profilers and measurement sensors are installed as in-line inspection systems, which allow for real-time monitoring and detection of defects while the product is still moving onto the production line.

Furthermore, the system is designed to flag the defective lead frame within a single metal strip. That flagged lead isn't cut out from the rest of the strip. Instead, it simply isn't used in any of the subsequent production steps.

Why Choose KEYENCE?

KEYENCE is the world's leading provider of precision measurement technologies used in many industries for industry-specific applications. If you're looking to enhance your quality control capabilities, don't hesitate to contact KEYENCE and inquire about the possible integrations of our equipment with your existing production lines.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity