CMM (Coordinate Measuring Machine)

How Do Laser Trackers Work?

Laser trackers are sophisticated instruments that have transformed the field of precision measurement. These devices provide reliable accuracy and versatility, making them irreplaceable tools for aerospace, automotive, shipbuilding, and other industries. The following will look at what laser tracking is, how trackers work, and the common applications that fuel the use of this equipment.

What Are Laser Trackers?

Laser trackers are precision measuring devices used for high-accuracy dimensional measuring applications. By combining laser technology, retroreflective targets, and specialized software, these devices can determine the exact coordinate position of a target object in three-dimensional space.

The compact size and portability of laser trackers allow these units to be transported and set up where the large measurement applications reside. This enables engineers and technicians to perform accurate measurements and alignments on-site at different job sites or manufacturing facilities. In addition, it minimizes the need for transporting the objects being measured to a dedicated measurement facility.

Discover more about this product.

Click here to book your demo.

Working Principles of Laser Tracking Systems

Laser trackers, for the most part, are relatively simple in their workings. They are built with a few main parts that help ensure accurate measurements and reliability. These components are the laser itself, the interferometer, the laser tracking software, and the retroreflective target, with the most common being an SMR (Spherically Mounted Retroreflector). The tracker first sends the laser beam to a target that is held against whatever object is being measured. The laser beam’s light then reflects to the tracker.

By measuring the difference between the emitted and received light waves, the laser tracker can precisely calculate the distance and position of the target. The main component that allows for that measurement to take place is the interferometer. This, in addition to the specialized metrology software, interprets the data and establishes the coordinates for the measurement.

We’re here to provide you with more details.

Reach out today!

Components of Laser Trackers

Laser trackers consist of several standard measurement components. These integral parts help operators measure large objects and determine the three-dimensional position of the target. From software to retroreflectors, camera bodies, and more, each plays an important role.

- Computer: The PC serves as the central hub to run the laser tracker operation software, enabling users to control and monitor the measurement process with precision and efficiency.

- Camera Body: When it comes to the actual laser tracker measurements, the camera body is a critical component, integrating both a light-emitting unit and a light-receiving unit. It shoots out the laser beam and captures the reflected light from the retroreflector. In short, the camera makes accurate measurement and tracking of the target object possible.

- Tripod: The tripod supports the camera body and provides stability during the measurement process. Its sturdy construction ensures that the camera body remains stationary and properly aligned. This is important for measurements big and small as it minimizes any potential sources of measurement error.

- Retroreflector (SMR): This component directly contacts the measured object. By reflecting the emitted laser beam to the camera body, the retroreflector can precisely measure the object's dimensions and features. Its design and placement allows for accurate and reliable measurement results.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Best Practices for Laser Tracker Maintenance

Maintaining a laser tracker is essential to ensure accurate and reliable measurement results over time. This helps manufacturers get the most ROI from their equipment. But what is involved in laser tracking maintenance?

Below is a list of best practices and tips to help you extend the life of your tools.

- Cleaning:

-

- Keep the external surfaces clean by wiping them down with a soft, lint-free cloth.

- Remove any dirt, dust, or debris that may accumulate on the tracker's components, including the measurement head, control unit, and portable base.

- Carefully wipe and clean the lenses, mirrors, and other optical components.

- Use approved cleaning solutions and techniques recommended by the manufacturer to avoid damage to sensitive optics.

- Calibrate the reflective targets periodically.

- Inspection:

-

- Inspect the components for signs of wear or damage regularly. Examine the cables, connectors, mounting hardware, and other accessories closely.

- Software:

-

- Keep your laser tracker updated by installing the latest firmware updates and patches as they become available. These updates provide bug fixes, performance improvements, and new features that enhance the tracker's performance.

- Proper Location and Storage:

-

- Store and operate the tracker in a clean, dry, and stable environment whenever possible. You will want to minimize the effects of temperature fluctuations, humidity, and airborne contaminants, like dust particles, on measurement accuracy.

Finally, one last tip that can go a long way is education. Operators must be trained on proper laser tracker inspection techniques, maintenance procedures, and safety precautions. All of the above proactive maintenance can help prolong the lifespan of your equipment.

We’re here to provide you with more details.

Reach out today!

The Proven Benefits of Laser Trackers

Laser tracking is being utilized daily by organizations worldwide for numerous reasons. This technology is advantageous over other measurement methods and will continue to be utilized for its benefits.

For one, laser tracking offers accurate measurements. This is often preferred over tape measures, calipers, and other measuring devices as those are often less accurate and prone to user error. Next, their portability and advancements in technology mean they can be installed and used nearly anywhere. Another benefit is the fact that trackers can offer real-time monitoring capabilities. What this allows is the ability to track the movement of objects over time, which is helpful for machine alignment and other uses.

Discover more about this product.

Click here to book your demo.

Industries and Applications of Laser Tracking Systems

The versatility of laser trackers makes them useful in a wide range of applications. They help with alignment during assembly processes, in-process inspection and final inspection, tool and mold building, calibrations, reverse engineering, and more. Because of this, many industries have realized the importance and benefits of implementing a laser tracking system into their operations.

Here are just a few industries and use cases where laser trackers excel:

- Aerospace Industry: Laser trackers play a crucial role in aerospace manufacturing and assembly processes. They are used for aligning and inspecting large aircraft components, ensuring precise positioning and dimensional accuracy. Laser trackers facilitate the assembly of complex structures such as wings, fuselages, and landing gear, contributing to improved aircraft performance and safety.

- Automotive Industry: In automotive manufacturing, laser trackers are utilized for quality control and dimensional inspection of vehicle components. They enable measurements of critical features, ensuring compliance with design specifications and tolerances. Laser trackers also aid in the alignment of robotic systems used in automotive assembly, optimizing production efficiency.

- Power Generation: Laser tracking is used in the power generation industry to align and maintain turbine components. It is instrumental in positioning rotor blades, shafts, and casings, which directly impacts the efficiency and reliability of power generation systems.

- Shipbuilding: Laser tracking is extensively employed in shipbuilding to support accurate construction and alignment of large ship structures. They assist in the positioning of hull sections, bulkheads, and other components, ensuring proper fit and alignment during assembly. Laser trackers contribute to the efficient construction of ships, reducing rework and enhancing overall productivity.

Besides these, many other industries also use laser tracking to save time and improve operations.

We’re here to provide you with more details.

Reach out today!

Advancements in Laser Tracker Technology

Over the years, laser tracker technology has evolved significantly, leading to enhanced accuracy, improved portability, and expanded measurement capabilities. Here are a few advancements that have helped laser trackers offer even more capabilities:

- Absolute Distance Measurement: Traditional laser trackers relied on interferometry techniques to measure the phase difference and calculate distances. However, recent advancements have introduced absolute distance measurement (ADM) technology. ADM uses a frequency-modulated continuous wave (FMCW) method, which enables direct distance measurements without the need for interference patterns. This technology eliminates the need for environmental compensation and improves measurement speed and accuracy.

- Wireless Connectivity: Another notable development in laser tracker technology is the integration of wireless connectivity. This innovation allows for seamless communication between the laser tracker and external devices such as laptops, tablets, or measurement software. Wireless connectivity eliminates the constraints of cables and enables greater flexibility in data collection and analysis, enhancing workflow efficiency.

As discussed, laser trackers are sophisticated instruments that leverage advanced measurement techniques to achieve amazing accuracy in distance and position measurements. With their ability to precisely capture three-dimensional data, laser trackers have become valuable. As technology continues to advance, we can expect further enhancements in laser tracker capabilities, opening up new possibilities for accurate and efficient measurement applications.

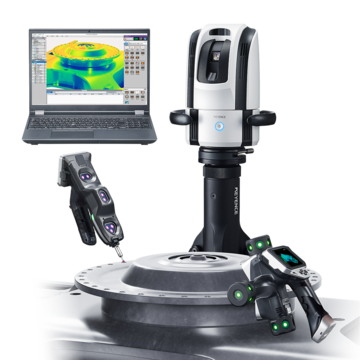

KEYENCE has been at the forefront of laser tracking/CMM machine technology. Our highly accurate, portable, and cost-friendly WM Series, Wide-Area CMM works like a laser tracker without having to overcome the obstacles of conventional laser trackers. Regardless of your industry and required application, our WM Series is sure to get the job done.

Ready to discuss your measurement needs? Reach out online or call us at 1-888-539-3623 today—we are happy to help.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the WM Series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

Related Products

Scroll

![WM Series Measurement / Application Examples [Fabrication Application Examples]](/img/asset/AS_116822_L.jpg)

![WM Series Measurement / Application Examples [In-Machine Measurement Examples]](/img/asset/AS_116821_L.jpg)

![WM Series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)