CMM (Coordinate Measuring Machine)

CMM for Defense Industry

Coordinate measuring machines, also known as CMMs, are measuring devices that collect geometric data based on coordinate points taken by a contact probe. Known for their efficiency and accuracy, CMMs are integrated into industries like aerospace, automotive, and defense.

Like other measuring and inspecting tools, there are multiple models and software to consider when purchasing a coordinate measuring machine. If you’re in the defense industry and weighing your CMM options, keep reading to learn how to make an informed decision.

How is the Government Utilizing CMM Machines?

In 1993, the Navy Manufacturing Technology program sponsored a study by the National Institute of Standards and Technology (NIST) to review the use of CMMs in the U.S. Navy. NIST found that there was a lack of skills, education, and overall use of CMMs. Although it’s been thirty years since—and the integration of CMMs has improved—there are still barriers.

The complexity of installing a new CMM machine, coupled with the already fast-paced energy of the defense industry, highlights the challenges that the industry is facing.

Nonetheless, the defense industry uses CMMs for measuring and inspecting parts, tools, fixtures, gauges, and reference standards. CMMs are defense metrology solutions that benefit production and maintenance, repair, and overhaul (MRO).

We’re here to provide you with more details.

Reach out today!

Choosing the Right CMM for Government Defense Application

When purchasing a CMM, there are four models to choose from: bridge/gantry, horizontal, cantilever, and arm. All of these models use a probe to take measurements.

Additionally, a lot of CMMs are automated nowadays and can import/export CAD models, so purchasing your desired CMM machine model also means considering what software you need. Let’s explore how to choose a CMM for defense.

Select the Proper Model and Software

Deciding on your model and software includes considerations like how skilled your technicians are, your measurement tolerance, where you’re measuring or inspecting, and the type of components you work with.

- Model

-

Gantry and bridge CMMs are popular in government applications because of their tight tolerance and stability. Because of their stable and accurate workability, these models are best for manufacturing and in-depth maintenance of defense equipment.

Cantilever and horizontal CMMs are not as accurate as gantry or bridge, but they still fit the industry’s tolerance. They have an ease of use that is helpful for quick measurements or general maintenance.

Arm and portable CMMs are the most flexible type of CMM because the probe can be used on the shop floor and goes where you need it to, when you need it to. As a dynamic industry with competing priorities, arm and portable CMMs work well for defense metrology solutions because of the flexibility for measuring and inspecting parts. - Software

-

Software is the middleman between you and the CMM.

Defense inspection and measurement applications are complex. Including software that calculates dimensions, creates reports, and analyzes data will improve your efficiency and accuracy.

Environmental control software that standardizes the environment is another beneficial software. Temperatures and contaminants affect dimensions, so this software calculates what the dimension would be with a neutral environment so you don’t have to.

Overall, software that is user-friendly and intuitive makes a world of difference when using a CMM. User-friendly software cuts down measurement and inspection time significantly and allows more technicians into the process even without extensive training.

Discover more about this product.

Click here to book your demo.

Integrating the CMM into Defense Manufacturing

If you are measuring or inspecting in the defense industry, you need a CMM with accuracy and flexibility to keep up with changing priorities. That’s why we offer handheld and portable CMMs that can meet defense industry demands.

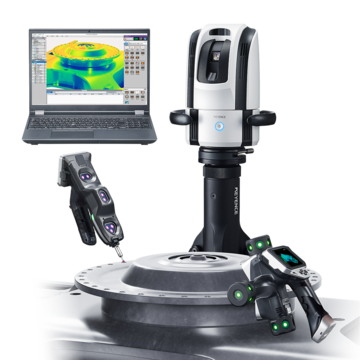

KEYENCE’s CMMs are used for final product inspections, prototyping, in-process inspections, and MRO because of their ease of use, ability to measure up to 82 ft, and easy to use software. Our CMMs fit defense industry standards and include statistical analysis, inspection reports, CAD model comparison, and environment control, so you have no extra administrative responsibilities. Contact us today for assistance or to get started.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM Series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM Series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)