CMM (Coordinate Measuring Machine)

Final Inspection

Have you ever bought a product and discovered it was recalled? Maybe it was your car that needed a new part or had electronics with potential safety issues. Regardless of the reason, recalls are a costly but often preventable issue.

These types of recalls are the result of inadequate final inspection. Final inspection, also known as pre-shipment inspection, is easy to overlook, but it’s absolutely necessary to ensure the products adhere to quality and safety standards.

It shouldn’t be an inconvenience to put out the best products for your customers. KEYENCE has your ideal inspection machine that expedites your process with a user-friendly interface, GD&T inspection, and manufacturing final inspection reports.

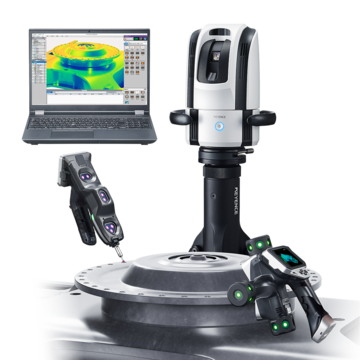

Atlantic Bearing Services (ABS) utilizes the KEYENCE XM-5000 handheld CMM to carry out final inspection on the shop floor to inspect large and small bearings.

What is Final Inspection?

Throughout the production process, parts are inspected before and during assembly. Production happens within a variety of locations, technicians, and inspection protocols. Because of this, it’s possible that the difference between these processes caused some type of defect from misaligned machines or other errors. It’s also plausible that a part was damaged during transportation. Because of these factors, parts require a pre-shipment inspection before being shipped out. This is known as the final inspection.

We’re here to provide you with more details.

Reach out today!

Why is Final Inspection Necessary?

A defective part or assembly is a massive risk to consumers, companies, and the supply chain. Shipping out a defective product can be a steep cut on your budget and brand reputation. Your company will have to pay for remedying the problem, which may include refunds, expedited re-manufacturing, legal fees, shipping, and slowing down other production to remedy the mistake. However, this can be avoided by inspecting your parts and the assemblies before sending them out for shipping.

Discover more about this product.

Click here to book your demo.

How to Conduct Final Inspection

Parts and assemblies need to be inspected using testing, measurement, and visual inspection to ensure the best product is going out the door. The inspectors record data from each of these inspections onto a final inspection checklist, also known as an inspection report. The parts and assembly must pass all final inspection requirements to be shipped out.

Visual Inspection

Visual final inspection is seeing if there are any visual deformities. For example, if a technician is inspecting a PCB and notices that one of the parts is falling off.

Testing

Final inspection testing ensures the functionality of the product. For instance, technicians inspect a car to make sure the brakes, engine, airbags, transmission, and other features of the car work.

Measurement

Measurement final inspection is confirming that measurements are accurate and fit the tolerances that the industry and product allows. In addition, measurement inspection verifies GD&T dimensions and features to make sure that the product is assembled correctly.

We’re here to provide you with more details.

Reach out today!

Get the Most Out of Your Final Inspection

Final inspection is necessary, but it’s also an infamously tedious process, especially if you work with products made up of many parts and elaborate assemblies. But final inspection does not have to be like this.

If you need an inspection machine for large parts, consider KEYENCE’s coordinate measurement machines (CMM). These portable and handheld devices allow you to bring the measurement device to the product instead of taking the components apart.

Looking for an inspection machine for small parts instead? Our image dimension measurement systems (IM) are automated optical comparators that automatically measure parts in seconds.

Cut down your pre-shipment inspection time from days to hours with KEYENCE’s quality and metrology systems which boast ease of use, GD&T inspection capabilities, and automated inspection reports. Want to learn more about making the transition? Contact us today to learn more!

Get detailed information on our products by downloading our catalog.

View Catalog

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM Series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM Series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)