CMM (Coordinate Measuring Machine)

CMM for Medical Device Industry

A coordinate measuring machine, also known as a CMM, is a metrology machine that is used for dimensional and GD&T measurements. CMMs use a probe to collect coordinate points and calculate measurements with software. A vision measurement machine (VMM) is an automated optical inspection system that can perform non-contact measurements to high degrees of accuracy and repeatability at the push of a button.

If you’re in the medical device industry, a CMM machine or an optical inspection system can be a great opportunity to add efficiency to your inspection, measurement, and reverse engineering processes—without compromising precision.

In this blog, we’ll discuss how to choose a CMM or optical inspection system for the medical device industry.

We’re here to provide you with more details.

Reach out today!

How CMMs and Optical Inspection Systems are Used in Medical Device Manufacturing

Medical device manufacturing is different from other manufacturing processes. For example, devices are oftentimes produced in small batches, defects have high stakes, and precision trumps all. Because of the care that goes into medical device manufacturing, efficiency isn’t always the top priority.

CMMs in the medical industry are often used for machined components, equipment assemblies, housings, mold verification, production machine alignment, and calibration. Because of their measurement accuracy and quality, optical inspection systems are often used for applications with tighter tolerances, like prototyping, implants, prosthetics, and other precision devices in the medical device industry.

Choosing the Right Device: CMM and Optical Inspection System for Medical Device Applications

Like most inspection systems, different models have different pros and cons for a range of applications.

CMMs work best for larger medical device applications with looser tolerances. Portable CMMs with CAD compare capabilities can help take quick and easy measurements on the shop floor, wasting less time inspecting and more time manufacturing.

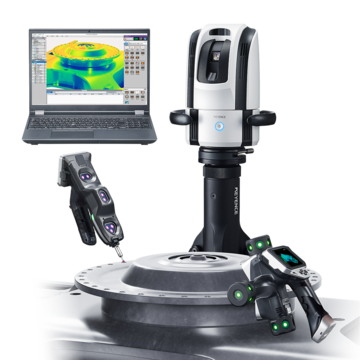

However, optical inspection systems like automated optical comparators or multisensor measurement systems can be ideal for higher-throughput or non-contact medical applications. These systems are great for smaller parts with really tight tolerances. For the highest precision, you’d want to look towards a multisensor measurement system with submicron accuracy, like the KEYENCE LM-X Series.

Discover more about this product.

Click here to book your demo.

Select the Proper Model

Portable CMMs are handheld and easy to maneuver. Instead of bringing your parts to the CMM for measurement, the CMM is brought to the parts. Using a portable CMM in medical device manufacturing works well for in-process inspections or if you don’t have a separate inspection or measurement room. Plus, even if you do have a separate room, portable CMMs can reduce time transporting devices to and from inspection areas and help to offload work for the automated CMMs that often experience back-ups.

Alternatively, bridge/gantry and cantilever/horizontal CMMs are usually immobile and measured in a separate room. Although bridge/gantry CMMs are known for precision, these CMMs lack the flexibility that portable CMMs have.

Because of the unique challenges medical devices often pose, optical inspection systems or VMMs offer the accuracy, precision, or flexibility of inspection that is often required and that a CMM may lack. The LM-X Series is a hyper-accurate, multisensor measurement system that helps inspect parts with a wide range of shapes, sizes, and materials.

Get detailed information on our products by downloading our catalog.

View Catalog

Select the Proper Software

The proper software for medical device manufacturing improves reverse engineering capabilities, time spent analyzing data, and precision with repeated production.

Data analysis software automates graphing, statistical analysis, and real-time inspection feedback. This software spots trends of incorrect inspections in real time so technicians can adjust or stop the device from moving further into the supply chain. Alternatively, the system can use this data for repetitive measurements or inspections for a batch of devices.

Another useful software is CAD model comparison. Measurement systems with this software are useful for the reverse engineering process because they automatically find the precise differences between the device and the model. With this at your fingertips, technicians can move quicker in the reverse engineering process.

Integrate the CMM and Optical Measurement Systems into the Medical Device Manufacturing Process

If you’re in the market for measuring tools in the medical device industry that will expedite your manufacturing process while holding onto precision, KEYENCE’s XM Series and IM or LM Series can get the job done.

The XM is a portable and handheld CMM machine that captures distances up to 2 m (6.6 ft) and all GD&T data. The integrated software includes 3D CAD model comparison and data analysis. With the data, the CMM machine creates traceability reports with trend graphs, statistical analysis, and histograms for you to pass along the supply chain.

For applications up to 12" or that require non-contact inspection, KEYENCE's IM and LM Series optical inspection systems are the best choice. These systems measure parts in seconds to submicron accuracies, for even the most critical tolerance requirements.

Contact us today for a free demo or to discuss any questions regarding these systems.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the IM-8000 Series Image Dimension Measurement System. Accurately measure parts in seconds at the push of a button.

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.