CMM (Coordinate Measuring Machine)

On-Machine Measurement

When conducting measurements in the manufacturing process, there are a few ways of going about it, depending on what is being measured. For many, either using on-machine measurement (OMM) or a coordinate measurement machine (CMM) on a separate shop floor are great options.

Between these two methods, there’s a debate over the better measurement choice. Considering the benefits and challenges of each, KEYENCE created a collaborative solution: a CMM used for OMM measurement. Between these two methods, there’s a debate over the better measurement choice. Considering the benefits and challenges of each, KEYENCE created a collaborative solution: a CMM used for OMM measurement.

Using these CMMs for on-machine measurement defeats the debate and brings them together for the best measuring capabilities. Keep reading to learn how KEYENCE uses the strengths of a CMM as an OMM machine for the ideal on-machine measurement.

The Debate: CMM and OMM Measurement

On-machine measurement is defined as measuring a part within the physical area of a machine (without moving it), usually using a probing feature of the machine that is also manufacturing the part. Standard coordinate measurement machines (CMM) measure in a separate measuring lab. Each measurement method has strengths and weaknesses that make technicians prefer one over the other.

Technicians who prefer on-machine measurement cite the ease of measurement because there is no movement of the part involved, allowing for less errors in the manufacturing process. Technicians enjoy the automated measurement attached to machinery that doesn’t require moving parts. On-machine measurement is often utilized for large productions, malleable materials, parts that should be removed from the chuck, or large products that aren’t easy to transport.

Technicians who prefer standard CMMs beg to differ. CMM supporters argue that the shop floor is too unpredictable with temperature, environment, and contaminants that alter the actual measurement of a part. Some wonder how it’s possible to trust a machine measuring itself. If the machinery is defective, wouldn’t that mean the additional OMM machine is too? Technicians who instead use CMMs say they would rather lose time transporting a part than have an inaccurate measurement.

We’re here to provide you with more details.

Reach out today!

The Solution: Use Portable CMMs for OMM Measurement

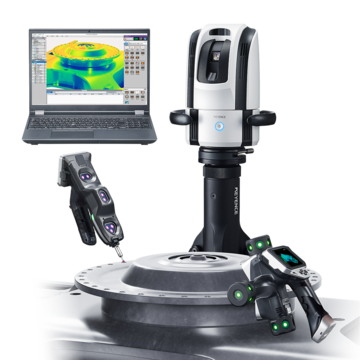

Clearly, there are flaws in using only OMM measurement or a standard CMM, so KEYENCE is bringing the CMM to on-machine measurement with the XM-5000 and WM-6000 CMMs. The XM and WM tackle standard CMM and OMM measurement issues.

Using a portable CMM as an OMM measurement tool ensures the efficiency and ease of measuring a part on a machine while still ensuring CMM precision.

With KEYENCE’s portable CMM, there is no need to bring a part onto a different shop floor. Instead, you move the CMM to the part and press the measurement button to define 2D, 3D, and GD&T features. The ability to bring the CMM to the machine for on-machine measurement eliminates any bottlenecks from transporting parts to a different CMM measurement floor.

KEYENCE’s portable CMMs come equipped with technology that tackles the unpredictability of the shop floor. They are easily maneuverable around unpredictable spaces by hand, on a stage, tripod, or cart, and have a temperature compensation function for volatile environments.

The temperature compensation function ensures that regardless of the shop floor environment, the CMM can adjust for measurements that align with the standard temperature. These additional features collaborate to ensure that the KEYENCE CMMs are the best CMMs for on machine measurement.

Get detailed information on our products by downloading our catalog.

View Catalog

Want to See Our CMMs in Action?

Instead of deciding between a CMM or OMM measurement, pick KEYENCE’s portable CMMs to get the most out of your equipment. Plus, enjoy all the benefits of OMM measurement and the accuracy of a CMM. Our clients consistently report that our CMMs reform their measuring processes into a streamlined method without bottlenecks.

Have questions or want more info? Contact us to request a demo today.

Discover more about this product.

Click here to book your demo.

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM Series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM Series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)