CMM (Coordinate Measuring Machine)

Machine Alignment

Being on a shop floor when one of your machines starts malfunctioning is a stressful problem. As this occurs across industries, this issue can have a number of costly consequences.

Whether it was a leakage, overheating, or a worn-down machine, there is a good chance that your machine was misaligned. But if you’re like many others who work with machinery, you know that machine alignment is a tedious task that sometimes gets overlooked.

At KEYENCE, we created coordinate measurement machines that can be utilized to aid with machine alignment. Keep reading to learn more about machine alignment practices and what you can do to proactively keep your machines running.

What is Machine Alignment?

A machine is made up of multiple parts and pieces that fit together into one machine, and aligning the elements within the machine is necessary for it to work.

The most essential element for machine alignment is the shafts. The shafts are rotating cylindrical-shaped metal elements that flow power through the machine. Misalignment happens when the shafts are unparalleled (unparalleled shafts) and/or at the wrong angle (angular misalignment).

We’re here to provide you with more details.

Reach out today!

Why is Machine Alignment Necessary?

Simply put, alignment keeps the machine at optimal power with its best efficiency. That being said, the consequences of misalignment are dire to machining.

Misalignment causes friction between the two shafts, and friction results in problems like heat stress, additional wear, breakage, and leaking. The heat stress and additional wear speed up the machine’s service life, and the machine will need to be replaced sooner than it’s supposed to. Breakage and leakage are threats to production overall, as they can cause the entire machine to malfunction.

The issues stemming from misalignment can cause more than a broken machine. A malfunctioning machine may process your batch defectively. Your time and budget are at risk without machine alignment.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

How to Check Machine Alignment Features

Parallelism and angularity/perpendicularity are two features that are critical to machine alignment. These should be checked after initial installation of a new machine. If you miss a machine alignment problem, the damage will already be done once you start the machine.

First, always check to make sure both feet of the machine are standing level on the floor. You might find that your machine is misaligned due to how your machine is standing, rather than a crooked shaft. If you’ve determined that that is not the case, bring in a portable coordinate measurement machine (CMM) as your alignment machine.

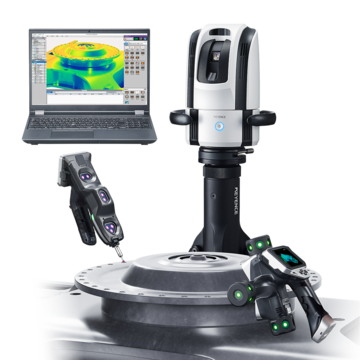

At KEYENCE, we recommend our handheld and portable CMMs for ease of use. If you’re using these, you’ll want to utilize the GD&T section to check features like angularity, parallelism, perpendicularity, and true position. Place and press the probe against your target to begin taking points to determine the alignment of the machine. The CMM takes only a few seconds to report back the coordinates to determine whether you need to fix your machine alignment.

If you need to realign your machine, slowly move the shafts to correct based on the CMM data. The most important part of checking alignment is that you continue to use the CMM until your machine is totally aligned.

Discover more about this product.

Click here to book your demo.

How to Choose a CMM to Be Your Alignment Machine

We recommend our XM or WM coordinate measurement machines as an alignment machine. The XM is best for smaller machines that fit in a 6ft or under range. If your machine is larger than that, for anything 6-82 ft, choosing the WM is a better choice.

Alignment is a crucial aspect of ensuring your machine works at its best capability. We know it can be tedious and time-consuming, so we have made machine alignment services easier. Contact us today to discuss your alignment questions or needs.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM Series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM Series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)