CMM (Coordinate Measuring Machine)

CMM for Plastics Industry

A coordinate measuring machine, also known as a CMM, is a metrology machine that is used for dimensional and GD&T measurements. CMMs use a probe to collect coordinate points and calculate measurements with software.

If you’re in the plastics industry, a CMM machine is an opportunity to optimize your inspection and measuring process. A portable CMM is your solution to moving efficiently through the inspection process while keeping your plastic molds intact. We’ll discuss how to choose a CMM for the plastics manufacturing industry.

How CMM Machines are Used in Plastic Manufacturing

Beyond final part inspection, CMMs play a significant role in the plastics industry. For example, they are often used as part of R&D and quality control in the production molds that are used for injection-molded components. This inspection process ensures that these parts meet specific standards and are defect-free.

Also, as mentioned, due to plastic's occasional sensitivity, there are other non-contact methods mixed into CMM inspection. However, larger metal molds don't have this obstacle and are ideal for CMMs.

We’re here to provide you with more details.

Reach out today!

Choosing the Right CMM for Plastic Manufacturing Applications

Like most machines, CMMs have multiple models with pros and cons for different applications.

CMMs have three main categories: bridge/gantry, cantilever/horizontal, and arm. For the plastics industry, the best CMM model to use is a portable CMM with adaptable software. Let's discuss why.

Discover more about this product.

Click here to book your demo.

Select the Proper Model

To select the proper CMM for the plastics industry, it’s best to pick one that can combat environmental changes, like variations in temperature or humidity. With these considerations, the proper CMM model for the plastic manufacturing industry is a handheld and portable CMM.

A handheld and portable CMM machine measures and inspects by bringing the CMM to the plastic part and touching a probe to it. This type of CMM does not require moving the plastic to another room or removing it from the mold.

Alternative CMM machine models—bridge, gantry, cantilever, and horizontal—require you to bring the plastic part or mold to the CMM. This frequent transportation can cause deformities due to temperature changes or handling. On top of that, the back-and-forth transporting of each plastic part is inefficient.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Select the Proper Software

The proper arm CMM software for the plastic manufacturing industry is software with temperature and vibration compensation, visual guidance, and CAD model comparison.

Temperature compensation measures the plastic at a standardized temperature. This provides insights into how the plastic will measure when exposed to a variety of temperatures. This is necessary, especially for plastic, because it changes with different environments. Likewise, vibration compensation will point out if vibration is getting in the way of accurate measurements.

Visual guidance is useful for repeated measurements to make sure everything is measured the same way with no variance between technicians. Errors between repetitive measurements can affect the rest of the batch, so every single part must be measured the same.

Discover more about this product.

Click here to book your demo.

Integrate the CMM into Plastic Manufacturing Processes

Implementing a coordinate measuring machine in plastic manufacturing will prevent defects and improve inspection repetition.

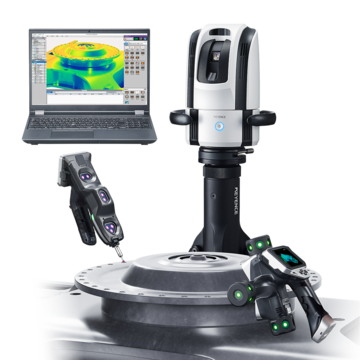

KEYENCE’s portable and handheld coordinate measuring machines are specialized for the plastics industry, featuring 3D CAD model color map comparison to spot deformities, visual guidance with a touch screen for consistency, and temperature compensation for neutral measurements.

Our CMMs, the WM and XM, transport between technicians in a rolling case and remain consistent with measurements no matter who is using it. Do you manufacture plastics up to 2 m? If so, the XM Series is the right tool for you. If you have larger components, you’ll want to check out the WM.

Contact us today for a free demo of our CMM solutions and to go over any questions you have.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM Series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM Series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)