CMM (Coordinate Measuring Machine)

Portable vs Fixed CMMs and How to Choose a CMM

Coordinate measuring machines (CMMs) are necessary tools for measurement and inspection in industries like aerospace, automobile, and medical devices. There are two types of CMMs, portable and fixed, and each has benefits depending on use.

When deciding between a portable or fixed CMM machine, understanding the key features that separate the two is imperative. In this blog, we’ll discuss what defines a CMM machine, the benefits of a fixed CMM machine, the benefits of a portable CMM machine, and the applications of each.

What is a CMM?

A CMM machine is a type of measuring tool that measures the geometry of a part by collecting points on a surface, usually by contact. Once the points are determined, the CMM machine utilizes a software to measure 2D and 3D dimensions, record data, and acquire GD&T features.

Fixed CMMs are known as the standard CMMs, which are generally designed as gantry or bridge types. The probe used is attached to the machine, and the machine maneuvers the probe onto the part. Alternatively, portable CMMs are generally handheld and have a manual probe that a technician controls.

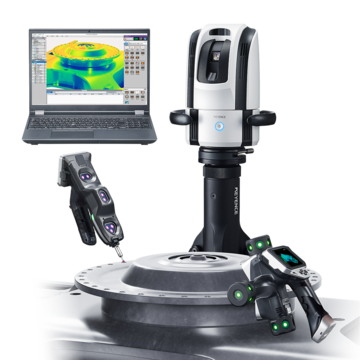

KEYENCE manufactures two versions of portable CMMs: the Handheld Probe Coordinate Measuring Machine XM-5000 and the Wide Area Coordinate Measuring Machine WM-6000.

Get detailed information on our products by downloading our catalog.

View Catalog

The Difference Between Portable and Fixed CMM

Both portable and fixed CMMs are accurate, user-friendly, and efficient when used in the correct scenarios. Choosing one over the other may not always have detrimental effects, but it will make your measuring process easier.

Benefits of Fixed CMMs

- Popularity

-

Fixed CMMs are recognized in the market as an accurate dimensional measuring systems.

- Automated

-

Oftentimes, fixed CMMs are also automated. This helps reduce the workload on an operator, but can create back up in the production line if the inspection program takes a while to run.

Benefits of Portable CMMs

- Efficient for Large Parts

-

Large parts are known as difficult to measure for a few reasons – weight, size, and difficulty transporting. Portable CMMs are handheld and lightweight, so their characteristics counter the difficulties of inspecting large parts. These devices work by physically going over to the part’s location and touching the probe to the desired measurement area. In some portable CMMs, like the WM Series, you can choose whether to use the portable CMM machine with a tripod or pole mount. Because of the portability, there is no more wasted time from hassling with heavy pieces.

Companies in industries like the aerospace and automobile industry have seen significant reductions in inspection time by being able to use KEYENCE’s portable CMM machines, the XM and WM Series around the shop floor with big parts. - Range of Measurement

-

Portable CMMs have a wide range for measuring small to large parts. The XM Series portable CMM machine measures parts from palm size to 2 m (6.6 ft) in width and 1m (3.2ft) in height. Likewise, the WM Series portable CMM machine can measure up to 25 m (82.0 ft) in width and 12.5 m (41.0 ft) in height.

- Highly Accurate

-

Portable CMMs are accurate and repeatable tools, especially when compared to their portable metrology counterparts like calipers, micrometers, and other manual gauges. KEYENCE’s portable CMMs follow NIST traceability standards for measurement and inspection.

- Cost

-

Portable CMMs are cheaper than fixed CMMs because there are no extra costs to introduce them as new devices. Portable CMMs are easily integrated into shop floors because of how little space they take up, so there is no need to spend money building an area for these tools. Additionally, portable CMMs are intuitive to use, so there is no extra cost for hiring new specialized technicians.

Portable CMMs: Applications

Below are examples of how KEYENCE’s CMM equipment has been applied for measurements.

Portable CMM: Handheld Probe Coordinate Measuring Machine XM-5000

Types of measurements:

- Hole distance, circularity, XY coordinates

- PCD, dividing angle

- Flatness, perpendicularity, parallelism

- Coaxility, symmetry

- Bending angle

- Distance between curved virtual lines

- Taper

- 3D CAD composition

Portable CMM: Wide Area Coordinate Measuring Machine WM-6000

Measurement examples:

- Large valve

- Heat exchanger

- Machine tool component

- Welding jig

- Steel construction frame

- Special-purpose vehicle components

- Conveying equipment

- Bridge components

Discover more about this product.

Click here to book your demo.

Ready to Pick the Best CMM For You?

Choosing between portable vs fixed CMM equipment is a decision that requires numerous considerations. If you are looking for a cost-effective, transportable, accurate, and versatile tool, choosing a portable CMM machine is probably best for you. But, if you need utmost accuracy, have a high budget, and measure large batches of small or sensitive parts, then choosing a fixed CMM machine may be the better choice.

More of a hands-on learner? Enjoy testing products hands-on before making a commitment? Contact our team at KEYENCE, and we will schedule a free demo so you can see our CMMs in action!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

Overcome inspections obstacles including common challenges with conventional handheld measurement tools and see why manufacturers choose the XM Series Handheld CMM as their first coordinate measuring machine.

See common coordinate measuring machine application examples measured on the XM Series Handheld CMM. Application examples include: turned parts, machined parts, stampings, castings, and molded parts.