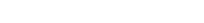

Internal structure of continuous inkjet printers

This section explains the internal path and ink circulation principle of industrial inkjet printers.

CIRCULATION PATH

Circulation principle

-

1Main tank

Stores the ink used in printing. Ink recovered from the gutter is also returned here.

-

2Pump

Pressurizes and feeds the ink from the main tank to the print head.

-

3Pressure reducing valve

Adjusts the ink pressure.

-

4Piezoelectric element

Oscillates the ink stream discharged from the nozzle to separate into ink particles.

-

5Nozzle

Discharges the ink.

-

6Electrostatic electrode plates

Applies a negative electric charge to the ink particles created from the ink stream.

-

7Electrostatic sensor

Monitors whether the ink particles have the proper electrostatic charge in them.

-

8Deflecting electrode plates

Generates a magnetic field between the electrode plates to deflect ink particles according to their charge. This directs ink particles onto the print target.

-

9Gutter

Collects the ink particles that are not used in printing.

-

10Pump

Retrieves the ink particles from the gutter and feeds them to the main tank.

-

1Main tank

Repeats the ink circulation.

- Solvent tank

- Supplies solvent to control viscosity when the ink in the main tank becomes too thick.

- Ink tank

- Supplies ink to the main tank when it is empty or when the ink is too thin.

![Learn the Basics of Continuous Inkjet Printers [CIJ Central]](/Images/ss_products_inkjet_header_title_1785688.gif)

![Inkjet Printer Tech Guide [Basic Knowledge Edition]](/img/asset/AS_114378_L.jpg)