Continuous Inkjet Printers / Case Coder

Date Coder Equipment and Date Coding Technologies

Date coding equipment is commonly used for printing expiration date, best by date, or manufacturing date on food packaging or products that require traceability. There are many factors to consider when selecting the right type of date coding equipment such as operating environment, production volume, materials being printed, as well as print content.

This section introduces the principles, characteristics, and pros/cons of each type of date coding equipment.

Types of Date Coding Equipment

Handheld Stampers

Type with fast-drying ink applied is pressed against the target to transfer the ink. With this type of technology, it's possible to print on target that can't easily be printed, but common problems are ink bleeding and improper drying.

Eliminate common problems with handheld stampers!

Handheld Labelers

Label applicators are commonly used in supermarkets and other retail stores. To apply the label, the user holds the grip and simply glides the device on the target surface. Handheld labelers offer high operability with dates and prices being displayed instantaneously.

Eliminate common problems with handheld labelers!

Click here to see inkjet printer application examples

Roller Stampers

With a roller stamper, the type is pressed against the object and the ink is transferred through rotation movement. This type of coding equipment must use water-based ink, and is commonly used for printing dates on cardboard or similar products being transferred on a conveyor.

Eliminate common problems with roller stampers!

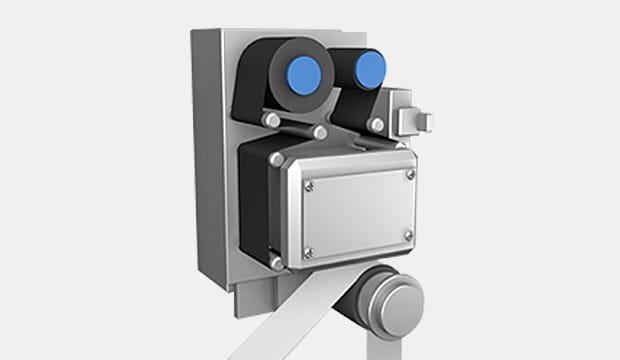

Label Printing Machines

Label printing machines are commonly used for batch printing with food products. Because labels must be water-resistant, thermal-based label printers that use an ink ribbon are generally used.

The main feature of label printing machines is that it gives user high flexibility to change print layout.

Eliminate common problems with label printing machines!

Click here to see inkjet printer application examples

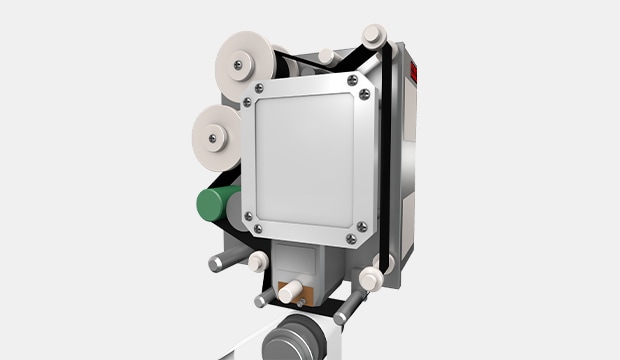

Hot Printers

Hot printers can be installed on pillow-type packaging machines or other automatic devices. Ink from an ink ribbon is transferred at high temperatures to the packaging film. These equipment are commonly seen on older packaging machines.

Eliminate common problems with hot printing machines!

Click here to see inkjet printer application examples

Thermal Printers

Unlike hot printers, thermal printers do not use type in the head for pressing against a target.

Instead, the printing head is heated electrically, and the ribbon transfers printed content to the target. Print content can also be changed easily.

Eliminate common problems with thermal printers!

Click here to see inkjet printer application examples

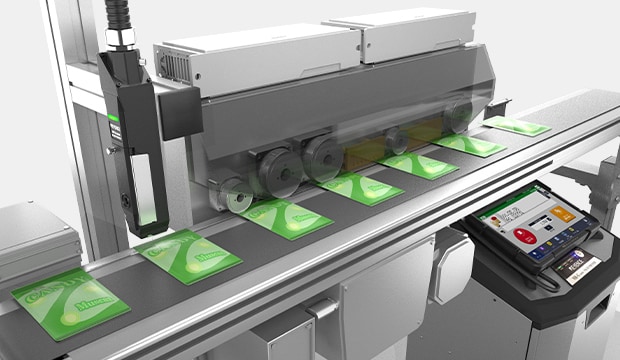

Inkjet Printers

Inkjet printers spray ink onto the surface of the target. This non-contact method printing ensures usage on a wide range of applications. Inkjet printers are also capable of printing on moving targets at high speeds from any direction or orientation.

We’re here to provide you with more details.

Reach out today!

Date Coder Equipment

Date coding equipment is an essential part of modern industries, used to label and code various products with information such as expiration dates, batch numbers, and product codes. The MK-G Series from KEYENCE stands out due to its robust design, corrective maintenance, automatic error detection, and ease of use.

Benefits of Inkjet Date Coders

Inkjet date coders come with specific benefits, such as high-speed printing, variable data printing, and wide substrate compatibility. Below is a more comprehensive list of benefits provided by inkjet date coders.

- High-speed printing — Continuous inkjet date coders rely on the highly pressurized continuous flow of ink for operation, allowing them to print onto substrates at an exceptional rate, especially compared to other industrial printing machines. Most models typically max out around 500 meters per minute, though some high-end models may print as fast as 1,000 meters of single-line text. This rapid printing speed allows for efficient and fast production lines, increasing productivity.

- Variable data printing — Variable data printing means the date coder is capable of printing different information, such as product manufacturing date, serial number, and other coding types. Furthermore, these settings should be accessible and adjustable from the printer’s interface. This capability ensures flexibility in the coding process and eliminates the need for manual coding or switching machines, which can be time-consuming and error-prone.

- Print resolution — Inkjet date coders are specifically designed to print high-resolution, crisp, clear, well-detailed date codes and simpler images. This is particularly crucial in industrial settings where print quality and legibility are important for reasons such as logistics, traceability, clarity, and legibility.

- Print quality — The overall print quality is another critical feature. It indicates that the date code produced by the inkjet date coder is legible, crisp, and without any smearing or other defects. Print quality is especially important for businesses dealing in consumer-facing products, mainly for maintaining brand standards. This ensures that date codes and other information remain clear and readable throughout the product's supply chain, from production to consumer’s hands.

- Wide substrate compatibility — Wide substrate compatibility, or the ability to print on a wide variety of different materials, is one of the biggest benefits of industrial inkjet date coders. These devices are capable of printing on metal, plastics, glass, paper, and a variety of other materials as well. Furthermore, the printer can be adjusted to the specific material needs and substrate shapes, making them highly versatile and adaptable for different production environments. Businesses can use the same device for coding multiple types of products, saving time and resources.

Cans

Packaging film

Cartons

Glass containers

Features of Date Code Printers

KEYENCE’s MK-G Series continuous inkjet date coder has a fantastic set of specific features that separate it from its competitors.

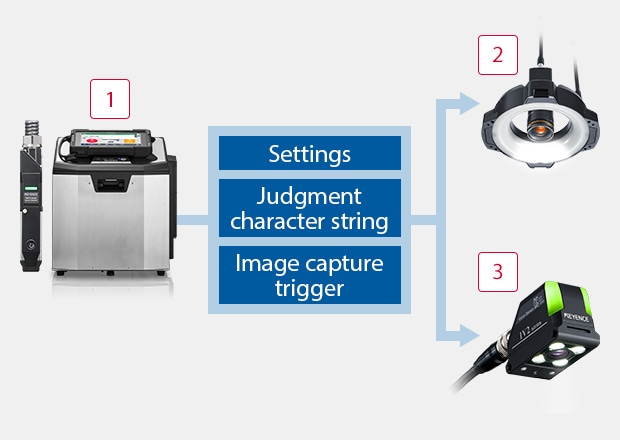

One of the most unique features of the MK-G Series that it can link up to various vision/inspections systems via a simple LAN connection. KEYENCE is the only company to manufacture marking and inspection systems. Turn on the built in IV link to instantly start presence absence inspecting your parts for the printed code from your MK-G Series inkjet coder. Take it a step further with CV link to fully OCR verify the contents of the printed codes. This eliminates the complex setup on the inspection systems as the MK-G Series populates all of that content with the push of a button.

Easily link to a print inspection device with just a LAN cable.

Direct connection to print inspecition equipment

The MK-G Series can be easily linked to a printinspection device by connecting a LAN cable.

Easily transfer settings, judgment character strings,image capture triggers, and more. Print inspection devices ensure products are not released if printeddetails are missing or incorrect, providing an extralayer of reliability.

-

1Continuous Inkjet Printer - MK-G Series

-

2Intuitive Vision System - CV-X Series

-

3Vision Sensor with Built-in AI - IV3/IV2 Series

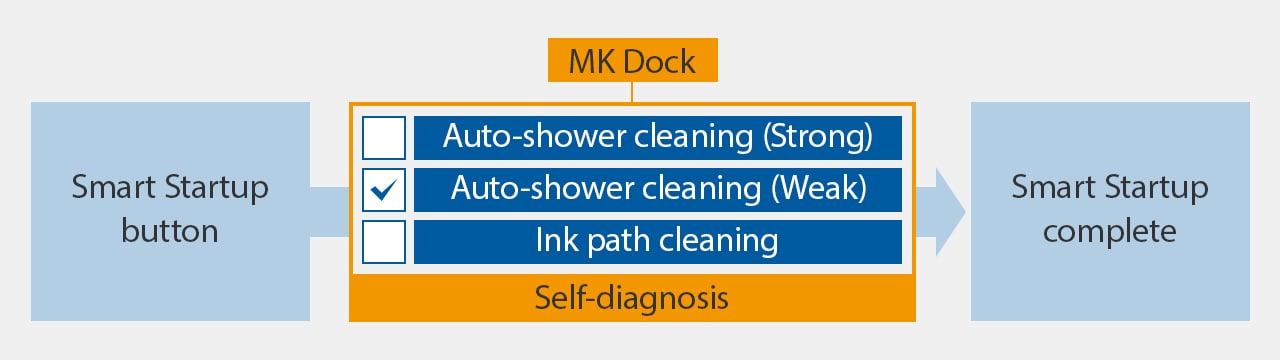

More importantly, the MK-G Series inkjet date coder is the world’s first self-troubleshooting continuous inkjet printer with plenty of troubleshooting and maintenance features. The inkjet date coder is capable of self-diagnosis and troubleshooting advice, which streamlines maintenance in case of common coding and printing errors, such as dirty print heads, clogged nozzles, and part replacements.

Uniform cleaning

There’s no need to clean the print head manually. Necessary operations can be completed by simply pressing a button, from cleaning to troubleshooting.

Conventional head cleaning

Manual cleaning had to be performed to remove ink that adhered inside the head.

Smart startup

Just placing the print head in the MK Dock starts optimal cleaning of the main head parts.

Optimized solvent usage

The printer performs a self-diagnosis and optimizesthe cleaning process, which also reduces theamount of solvent used.

Importance of Date Coding Equipment in Various Industries

Though often taken for granted by end-consumers, date coding conveys important product-related information. For example, date coding on perishable goods serves to help consumers and retailers determine product freshness and remaining shelf life, while lot and production batch numbers help manufacturers identify defective products.

This type of coding is often mandated by regulatory bodies governing different industries, as it relates to safety information and compliance, on top of inventory management and brand integrity.

Interested in improving your date coding process? Look no further than KEYENCE's MK-G Series continuous inkjet printers! With advanced features such as LAN connectivity and self-troubleshooting capabilities, our printers provide unparalleled reliability and print quality.

Contact us now to learn more about the MK-G Series and how it can benefit your business.

KEYENCE ultra-high-speed and non-contactindustrial inkjet printers can be easily installedon existing packaging machines.

Through built-in sensors and optimization, flawless and clear marking of expiration datescan be achieved.

Get detailed information on our products by downloading our catalog.

View Catalog

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)