CMM (Coordinate Measuring Machine)

Types of CMM Machines: How to choose a CMM?

Coordinate measuring machines (CMMs) are efficient and accurate measuring tools that outperform alternatives like rulers, micrometers, and vernier calipers. These versatile machines measure the 3D dimensions, GD&T features, and compare to CAD in industries like healthcare, automobile, aerospace, and more.

However, not all CMMs are created equal– but that’s good news! CMMs have different measurement areas, software, and accuracy. Each of these factors should be taken into account when choosing the right CMM for your inspection or measurement needs.

With that said, if you are wondering how to choose a CMM, the following post will help.

What are the Different Types of CMM Machines?

There are three conventional types of CMM machines: bridge/gantry, cantilever/horizontal, and arm.

- Bridge/Gantry

-

Bridge/Gantry CMMs are a type of CMM consisting of a bridge-like structure supporting the probe’s movement across the stage. Gantry-style CMMs are built for larger parts and are floor-mounted, while a classic “bridge” style CMM is not always floor-mounted.

- Horizontal/Cantilever

-

Horizontal and Cantilever CMMs both use a side-mounted “arm” that moves a probe either up and down (cantilever) or side to side (horizontal) to inspect parts.

- Arm

-

Arm-type CMMs are jointed machines that use encoders to track the angle of each joint and use math to determine where in space the probe tip is.

At KEYENCE, we offer non-conventional portable handheld CMMs that work to replace conventional CMMs. In this blog, we’ll discuss CMM options in relation to accuracy, part size, and software.

Discover more about this product.

Click here to book your demo.

Key Factors in Choosing the Right CMM

Although there are different types of CMM machines, narrowing down your choice doesn’t have to be difficult. Usually, this decision involves several important factors that are easy to identify. These include your specific manufacturing requirements or needs, desired features, cost, portability, ease of use, and more.

The below will help you find the right CMM for your applications and make your quality control process more efficient.

We’re here to provide you with more details.

Reach out today!

Defining Your Specific Measurement Requirements

When selecting a CMM machine, first define your specific measurement requirements. As we know, most applications, parts, and components are unique.

Consider the type of parts or components you will be measuring, the level of accuracy needed, and the complexity of the geometries involved. Are you primarily measuring simple parts or more complex freeform surfaces?

Also, consider the size and weight of the parts you will be measuring. Would a portable, handheld coordinate measuring machine make more sense than a fixed unit? Some CMMs are designed for small, lightweight parts, while others can handle larger, heavier components.

You should also consider your operation's throughput requirements. Do you need high-speed measurement capabilities for better output? Is precision more important to you than speed? Are you trying to speed up and reduce costs for in-process inspection?

Thinking through these types of questions and proactively defining your requirements will help you better evaluate the CMM measuring capabilities that would work best for you.

Evaluating CMM Features and Capabilities

Once you have defined your measurement requirements, it's time to evaluate the features and capabilities that will help meet those needs. Consider features like speed, repeatability, and resolution. Based on your application and the level of automation required, discuss whether you need a manual, CNC, or robotic CMM.

Additionally, examine the software options available for each CMM. User-friendly software with intuitive interfaces can streamline the measurement process and improve productivity. Look for CMMs that offer software with the right mix of analysis and reporting capabilities. You want to find software that makes it easy to view and use insights from your measurement data to improve operations.

Other important features to consider include budget and ROI, sensor compatibility, and measurement accuracy. Because CMMs can vary in price, it is a good practice to look at the financial impact your equipment will have on the bottom line.

Considering Budget and ROI

Your budget and the CMM's return on investment (ROI) can impact your choices. While it's essential to choose a CMM that meets your measurement requirements, you should consider the long-term return a great CMM can provide. Evaluate factors such as initial purchase price, improved output volume, cost savings, and more.

What is the potential ROI of investing in a high-quality CMM with advanced features and capabilities? Will the increased accuracy and productivity outweigh the higher upfront cost? Conduct a cost-benefit analysis to determine the most cost-effective option for your operation.

For example, a handheld CMM is more cost-effective than a fixed, automated CMM. They take up little space, so there is no cost for building an area specifically for them. Because they are so easy to use, there is no extra cost for hiring or training technicians. These and other factors can have positive financial impacts on your operation.

Importance of CMM Measurement Accuracy

When discussing CMM accuracy, we aren’t discussing whether a CMM is accurate or not; rather, how a CMM aligns with an industry’s accuracy spectrum. All CMMs are accurate, but analyzing the comparison of the accuracy is crucial for deciding which is best for you or the task at hand.

Bridge CMMs are generally used in environmentally regulated quality control rooms which require; air-conditioning for temperature and humidity control, air filters for dust and particulate control, vibration isolation equipment, and other factors for situations where high-accuracy measurements are required. It typically requires a dedicated and certified CMM programmer who has specialized training to operate the system. On the other hand, arm CMMs are also used on the production floor and are often used in cases where accessibility is a higher priority than accuracy.

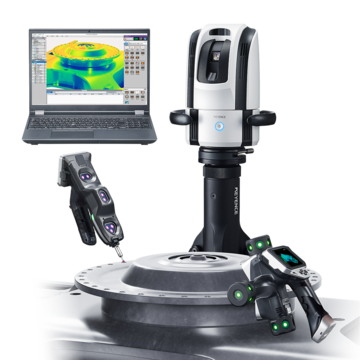

Out of KEYENCE's two CMM options, the most accurate is the KEYENCE XM Series Handheld CMM. It can be used on the shop floor or in a quality room, and has a measurement range of up to 6ft, making it extremely versatile for everyday use.

Secondly, we have KEYENCE’s WM-6000 Wide Area Coordinate Measuring Machine. This CMM is ideal for anyone performing large part or equipment inspection, machine alignment, and manual measurement processes that require multiple inspectors since the WM only requires one user to measure parts up to 80 ft.

Measurement Area

- Small Parts

-

Do you manufacture parts that could fit in a 6ft or less area? If this resonates with you, the XM Series handheld CMM is the best CMM machine for your parts.

You can place parts directly on the stage of the KEYENCE’s XM-5000 for measurement or use the tripod and bring the XM to your parts for in-machine measurement. If you choose to use the XM stage, it has a built-in fixture plate to make it easy to secure parts quickly for inspection. Conventional bridge CMMs use an overhead probe, require a temperature-controlled clean room, and cannot be moved on the shop floor, but KEYENCE’s XM Series is a versatile CMM that can be operated anywhere needed, by anyone, making quality checks a breeze. - Large Parts

-

Do you measure auto body parts, aerospace equipment, or construction machines? No matter what type of large parts or equipment you measure, you’re all too familiar with the restricted measurement area, high maintenance costs, and difficulty of single-person inspection that comes with large parts. These parts can’t fit on a bridge CMM stage and are a pain to move around the shop floor, so a portable CMM is your best CMM machine option.

Portable CMM machine types are handheld and transportable across shop floor locations. These CMMs are brought to the part in which the operator touches the device probe to the part. The CMM instantaneously records measurements and creates inspection reports. KEYENCE offers a wide variety of handheld CMMs with maximum measurement ranges to suit many applications.

If you’re looking for something to handle these larger jobs, the WM Series is your best CMM machine option. The WM Series reaches a maximum measurement size of 25 m. The system can be freely moved around the shop floor, even coming with a mobile roller case for easy transportation. This enables you to travel to those large parts and equipment for measurement and inspection.

CAD Software

Using a CMM for comparisons with molds and castings is a common practice, but it can be time-consuming without up-to-par types of CMM software. If you’re looking to use a CMM for inspection, choosing a CMM with CAD comparison functions is an ideal choice.

All of KEYENCE’s CMMs provide CAD software, so the material or part size you’re using is the determining factor for which CMM is the best fit.

Get detailed information on our products by downloading our catalog.

View Catalog

Ready to Try a CMM?

Different types of CMMs each have specifications that make them ideal for particular measuring or inspection needs.

If you are measuring or inspecting parts under 6ft, the KEYENCE XM Series is the choice for you, and for anything larger, be sure to check out the KEYENCE WM Series.

Still unsure how to choose a CMM for your organization? Contact KEYENCE today, and our team will schedule a demo with your team ASAP!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

![Perfect for High-Mix, Low-Volume Work Handheld Probe Coordinate Measuring Machine [Easy 3D and GD&T Measurement]](/img/asset/AS_116420_L.jpg)

The XM Series Handheld CMM is perfect for high-mix and low-volume work. See examples in this technical guide.

See common coordinate measuring machine application examples measured on the XM Series Handheld CMM. Application examples include: turned parts, machined parts, stampings, castings, and molded parts.

Using customer feedback, we compiled the 3 primary reasons they chose the XM Series as a complementary measurement system to their existing measuring equipment or CMMs.

An informative guide offering fundamental information related to dimensional measurements in manufacturing, including how to select the right tool for the job. Learn a wide array of inspection knowledge including optical comparator and coordinate measuring machine (CMM) basics.