CMM (Coordinate Measuring Machine)

Laser Tracker

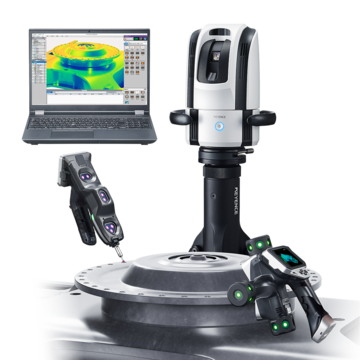

Introducing KEYENCE’s WM Series, a wide-area CMM that resembles the look and functionality of a laser tracker without the common issues. This device has a dedicated wireless probe that eliminates movement restrictions when measuring large targets. Measurements by the laser tracker can also be performed virtually anywhere with no need to take targets to a metrology lab, helping to reduce the time spent on measurement and improving operating rates. In addition, the laser tracker has great accuracy—in the μm range—eliminating variations in measurement results for parts with complex shapes requiring high accuracy, including turbine blades.

What is a Laser Tracker?

A laser tracker is a measuring device that works by projecting a laser beam onto an optical target in contact with an object being measured. The device then determines the three-dimensional position of the target. The optical targets are known as “retroreflective” because they reflect the laser tracker beam back to its emitted origin point – typically known as a spherically mounted retroreflector (SMR). Dimension values, angles, geometrical tolerances, etc., are determined by software that calculates the 3D coordinates of the retroreflector.

Understanding a Laser Tracker

Laser trackers are characterized by the ability to measure large objects. Laser trackers generally have a measuring range of more than 10 m 30', whereas a standard arm-type CMM has a maximum measuring range of a couple meters. It is useful in situations where you want to measure large objects such as airplanes, parts of large equipment, and parts produced by double-column, 5-face milling machines.

Laser Tracker Components

The laser tracker measurement components that make up a laser tracker are generally divided into four parts.

A PC to run laser tracker operation software, a camera body that integrates a light emitting unit and a light receiving unit, a tripod that supports it, and a retroreflector (SMR) that contacts the object to be measured.

We’re here to provide you with more details.

Reach out today!

Principle of a Laser Tracker

The laser tracker calculates the center coordinates of the retroreflector (SMR) from the distance and angle information from the horizontal and vertical two-axis rotary encoders. The laser tracker body follows the laser light by rotating in horizontal and vertical directions.

The retroreflector (SMR) has a mirror surface inside, and no matter what angle the laser light is received, it returns the light in the direction in which it came. The retroreflector (SMR) is in the shape of a true sphere, and the light is always reflected from its center so that the center coordinates of the sphere of the reflector itself can be obtained.

KEYENCE’s WM Series looks and functions similarly to a laser tracker, using line-of-sight tactics to take measurement points, but rather than using a laser beam, the WM Series utilizes near infrared light to see the probe and take points. This reinvents classic techniques for measuring large parts, and eliminates the common issues of traditional laser trackers.

Discover more about this product.

Click here to book your demo.

Benefits of KEYENCE’s WM Series Laser Tracking CMM

Single-Person Measurement of Large Targets

The WM Series uses a handheld probe, making it possible for individual workers to measure large parts and equipment that would require several people with conventional laser trackers. In addition to a wide measurement range, the freedom of movement provided by the wireless probe allows for fast measurement, even with time-consuming and difficult measurements, helping to reduce both effort and costs.

Fast, Highly Accurate Measurements

The WM Series can be used to measure 3D features and GD&T over a wide measurement range in less time and with higher accuracy than tape measures, calipers, or micrometers. The WM Series is also able to import 3D CAD data for comparing differences with actual targets.

On-the-Spot Measurements With No Need for a Metrology Lab

Because the WM Series is portable and can be installed virtually anywhere, it eliminates the need to move targets to a metrology lab/quality room and open the door to a wide variety of applications, such as checking targets on manufacturing machines and performing periodic inspections during operation.

User-Friendly

The WM Series was created with users in mind, from beginners to metrology experts. First off, KEYENCE’s WM Series only requires three simple steps: select the tool on the touch screen, touch the probe to the part, and press measure. If that’s not intuitive enough, there are video and picture tutorials that walk through the processes and different functions. A major advantage for ease of operation and understanding is the augmented reality measurement guidance, which overlays the measurement data over a picture of the physical part.

Get detailed information on our products by downloading our catalog.

View Catalog

Key Features of KEYENCE’s Laser Tracking CMM System

Statistical Analysis

KEYENCE’s WM Series, similar to a laser tracking system, has built-in statistical analysis software. This feature reduces time spent on manual statistical analysis separate from the measuring process. The measuring tool’s statistical analysis function can extract these analyses:

- Maximum/minimum value

- Pass/fail

- Average

- σ, 3σ, 6σ

- Cpk

- Increased variation trends

- Upward/downward measurement trends

- Periodic fluctuations

- Histograms

3D CAD Data Comparison

The WM Series has software that can compare a part to a CAD model/file. Typically, laser trackers take individual points to produce measurement data, but with the WM Series’ auto-trigger function, rapid point data can be gathered for highly-detailed and accurate point clouds and color maps are created for profile and contours.

Wide Range of Measurement

The WM Series has a wide range of measurements that is suitable for even large machinery. The laser tracker measurement tool has a horizontal measurement range of 15 m and a vertical measurement range of 12.5 m. Also, since the device is portable, it can measure this large equipment by handheld, tripod, extension pole, or cart.

Temperature Compensation Function

The temperature compensation function of the WM Series can adjust its temperature to match that of a climate-controlled measuring room. With this feature, measuring can continue even if there isn’t readily available access to a separate measuring room.

We’re here to provide you with more details.

Reach out today!

Laser Tracker Case Studies

Application Example 1: Dimensional Measurement of H-shaped Steel Beams

H-shaped steel beams are an essential material in civil engineering and building construction. Conventional methods for measuring these beams involve multiple workers using calipers or tape measures, which can be time-consuming. KEYENCE’s laser tracker makes it possible to measure the shape, joined section finish, and welding shrinkage amount using the wireless probe.

Application Example 2: Leveling of Industrial Machinery

Leveling is an important step when installing industrial machinery, equipment frames, or base frames. Equipment or devices installed at an angle could lead to malfunctioning products or parts, or the equipment itself could become damaged due to unexpected loads. Using a laser tracker makes it easy for even individual workers to perform leveling quickly for significantly reduced time spent on setup.

Application Example 3: Vacuum Chamber Dimensional Measurement

Vacuum chamber quality depends greatly on semiconductor device performance. Leaks (vacuum leaks) that allow air to enter through gaps in the vacuum chamber and degassing caused by poor bonding or other causes must be prevented as these factors could lead to defective semiconductor devices. Using a laser tracker to accurately measure the shapes and dimensions both before and after assembly can significantly improve quality.

Discover more about this product.

Click here to book your demo.

Laser Tracker Application Examples:

Example 1: Large Valve

With a large valve, the laser tracker can measure the distance between the center and the edge as well as the intersection point. Valves also have holes that can be measured by using the plane function.

Example 2: Heat Exchanger

On a heat exchanger, the plane function on the laser measuring tool can be used to measure the flatness.

Example 3: Machine Tool Component (Column)

With a machine tool component column, the plane function on the laser tracker is often utilized to measure the flatness or parallelism.

Example 4: Bridge Components

On a bridge component, the laser tracker can measure the top with the plane function. If there are slot centers, the laser tracker can use the rectangular slot center or the circle center function.

FAQs About Laser Tracker

How do laser trackers work?

A laser tracker emits a laser beam toward a retroreflective target, often a spherically mounted retroreflector (SMR), which is placed on the object that is being measured. The laser light is reflected by the SMR and upon re-entry into the tracker, a distance meter within calculates the precise distance between the tracker and the retroreflector. The captured coordinate data is then transmitted to metrology software, which establishes the X, Y, and Z coordinates for the measured point to construct dimensional measurements like lines, diameters, angles, etc. The KEYENCE WM Series is a new take on a laser tracker, allowing large parts to be measured using only infrared light.

How accurate is laser tracker measurement?

Laser trackers have the potential to be incredibly accurate in the Y axis. While still accurate, because of the technology used by laser trackers, the accuracy for laser trackers is lesser in the X & Z axes. Conversely, KEYENCE CMMs are the opposite, being more accurate in the X and Z, and less accurate in the Y.

What is the range of a laser tracker?

Laser trackers can have substantial range. Laser trackers are ideal for measuring the length of sizable parts. For example, they’re great for parts in the construction, aerospace, & naval industries. The KEYENCE WM Series is great for parts in the 6-82 foot range. For most companies, a laser tracker is "overkill" for that type of application. The WM Series can accommodate larger parts, up to ~ 82 feet wide in a single setup. The WM Series was designed to fill a gap where parts are too large or cumbersome for traditional CMMs that need quick or complex inspection, and parts that are smaller than necessary for laser trackers. The WM maintains accurate measurements, ease of use, and no warm-up time, which is unparalleled to alternative products.

What types of probe tips can a CMM use?

KEYENCE CMMs use M5 threaded, spherical (or hemispherical) probe tips. Because of the technology used, the part of the tip touching the feature must be spherically rounded, but any probe tip of this fashion can work with KEYENCE's CMMs.

Where can a wide-area CMM be used?

KEYENCE's CMMs are portable so they can be used anywhere. Ideally they should be used in environments with 32-104 degrees Fahrenheit with 20-80% relative humidity. While our systems are almost exclusively used on the shop floor or in a quality lab, we have successfully used our systems outdoors, despite that not being their traditional use.

Related Downloads

Brochure for the WM Series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

Related Products

Scroll

![WM Series Measurement / Application Examples [Fabrication Application Examples]](/img/asset/AS_116822_L.jpg)

![WM Series Measurement / Application Examples [In-Machine Measurement Examples]](/img/asset/AS_116821_L.jpg)

![WM Series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)