Chapter 5 I/O Control and Timing Charts

List of Communication Commands for Control

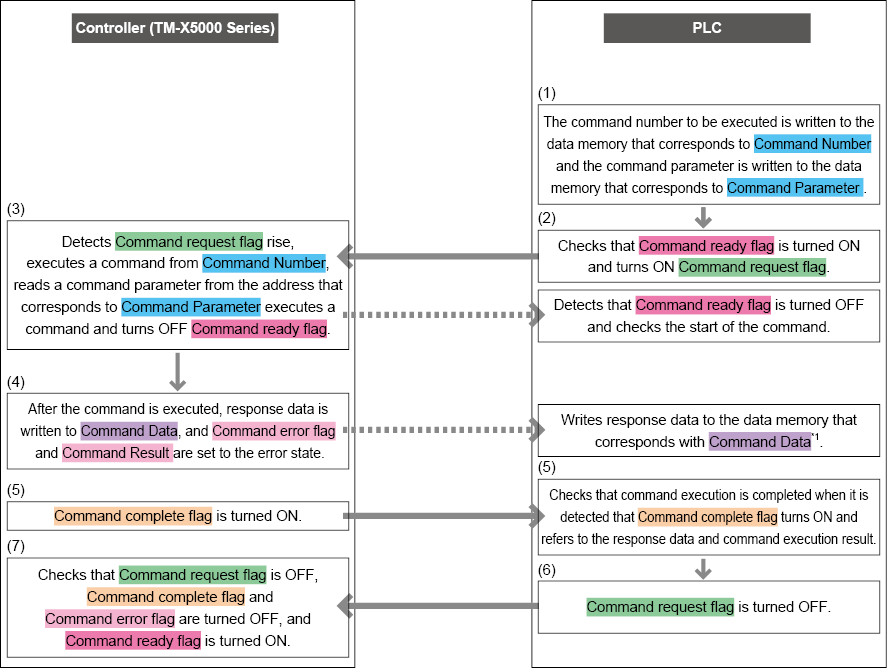

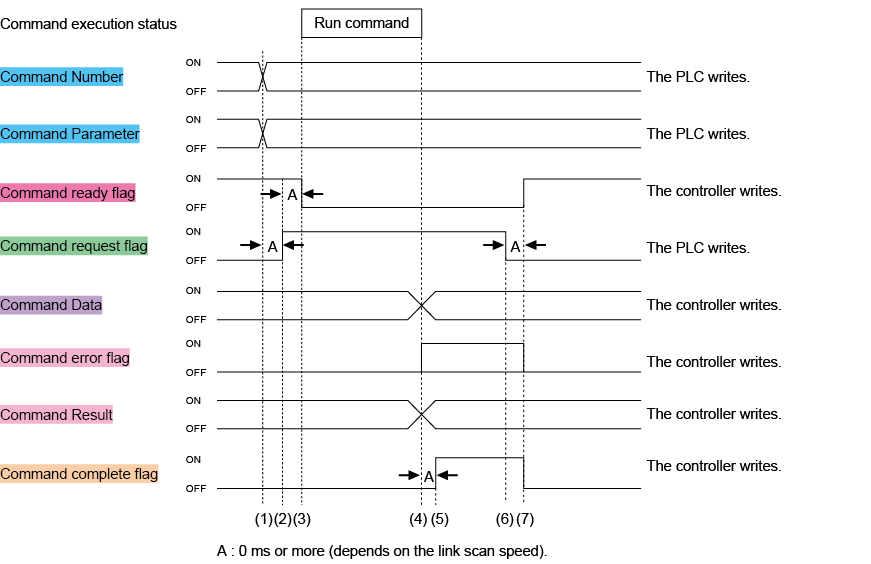

Notes on Command Input/Output

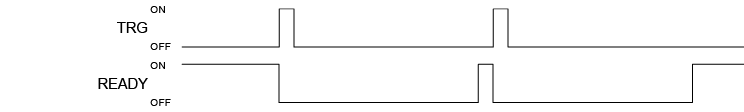

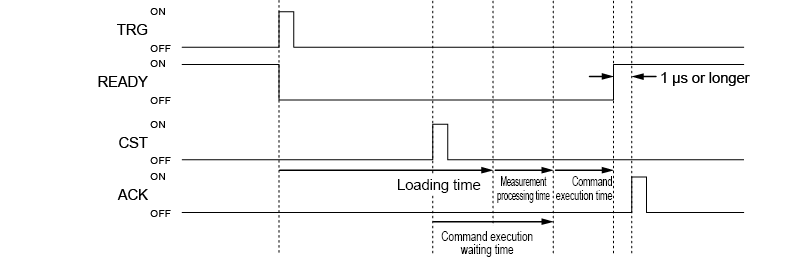

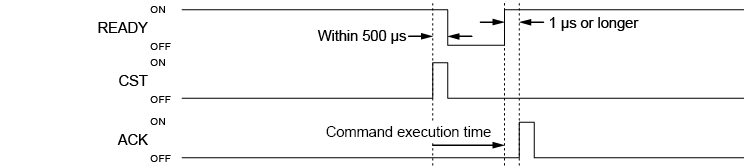

When using non-procedural commands

Command input during operation

- Command input is accepted during operation. However, if commands need to be executed in a high-speed operation line, remember that execution of commands may suspend trigger acceptance.

- The execution time of a command depends on the amount of load on the controller and the type of operation performed by the controller. For the use in which a program must wait for command execution to be completed before starting the next inspection, be careful of the waiting time fluctuation according to the conditions mentioned above.

Number of characters for command parameters

Any number of parameter characters within the range specified for each command can be entered.

When an error occurs upon command acceptance

An error response “ER, **, nn” will be returned.

The error response consists of the following information:

|

** |

Received command that caused the error |

|

nn |

2-digit error code

|

An example of error output

When the No. 1005 (unavailable number) is specified for program No. changing command (PW), “ER,PW,22” is returned as response data.

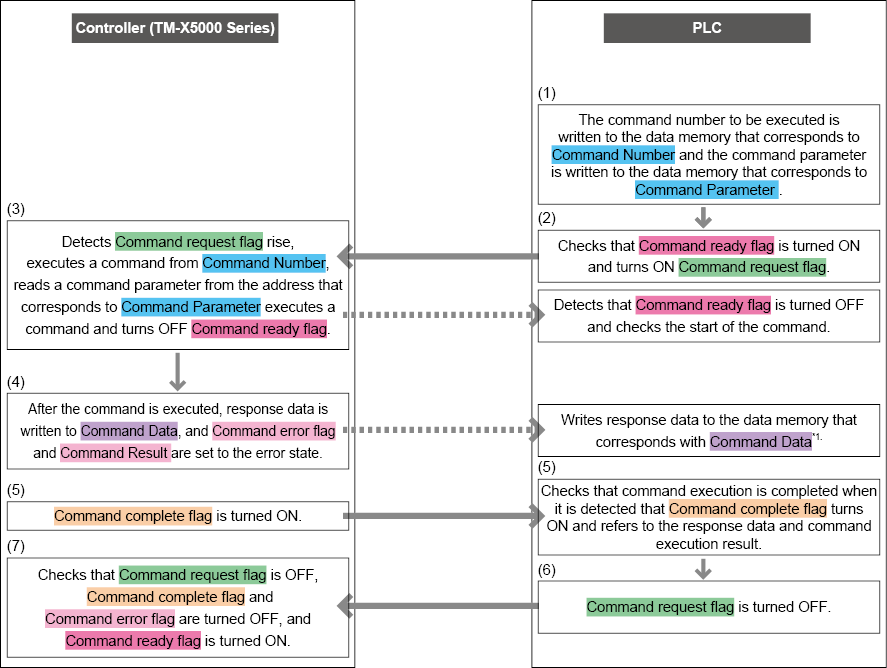

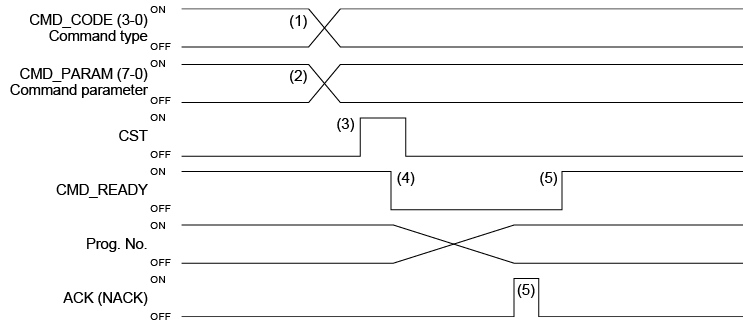

When using number-specified commands

Specification and execution of each command number is processed in 1 word.

Command input during operation

Command input is accepted during operation. However, if commands need to be executed in a high-speed operation line, remember that execution of commands may suspend trigger acceptance.

When an error occurs upon command acceptance

The error code is written in the command result address as the execution result. The error response consists of the following information:

|

0 |

Success |

|

02 |

Command error (The received command is invalid.) |

|

03 |

Command action disabled (The received command cannot work.) |

|

22 |

The number or range of the parameter is incorrect. |

An example of error output

When the No. 1005 (unavailable number) is specified for program No. changing command, “22” is written in the command result address as binary data of 1 word.

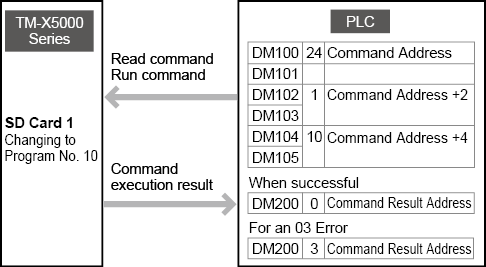

Example: Changing the current program No. to program No. 10 stored in SD card 1 using the PLC-Link.

The detailed command assignments for this example is shown below.

List of Operation Modes and Available Input Commands

= Possible

|

Command type |

Function |

Command name (No protocol) |

Command number (Field network) |

I/O terminal command support |

Run |

Setup |

Block*6 |

|

Trigger |

Trigger |

T1 |

1*1 |

×*3 |

|

|

× |

|

System control |

Switch to run mode |

R0 |

8 |

× |

|

|

|

|

Switch to setup mode |

S0 |

9 |

× |

|

|

× |

|

|

Reset |

RS |

10*1 |

×*3 |

|

× |

x |

|

|

Reboot |

RB |

11 |

× |

|

|

x |

|

|

Save Program |

SS |

12 |

|

|

|

x |

|

|

Clear error |

CE |

13*1 |

|

|

|

x |

|

|

Read run/setup mode |

RM |

16 |

× |

|

|

|

|

|

Change inspection program |

Change inspection programs |

PW |

24 |

|

|

|

x |

|

Read program setting |

PR |

25 |

× |

|

|

x |

|

|

Measurement control |

Change recipe |

EXW |

41*2 |

|

|

|

x |

|

Read recipe |

EXR |

42 |

× |

|

|

x |

|

|

Timing |

TIM |

52*1 |

*4 |

|

|

x |

|

|

Auto zero |

ZR |

53*1 |

*4 |

|

|

x |

|

|

Reset measured value |

MRS |

54*1 |

*4 |

|

|

x |

|

|

Reset measured value (all templates) |

RSA |

55*1 |

*4 |

|

|

x |

|

|

I/O control |

Enable/Disable Trigger Input |

TE |

56 |

×*3 |

|

|

x |

|

Enable/Disable Output |

OE |

57 |

×*3 |

|

× |

x |

|

|

Utility |

Replace the externally specified string |

STW |

60 |

x |

|

|

x |

|

Read the externally specified string |

STR |

61 |

x |

|

|

x |

|

|

Clear Archived Image |

HC |

66 |

× |

|

|

x |

|

|

Change Output File/Folder |

OW |

69 |

|

|

× |

x |

|

|

Echo |

EC |

- |

× |

|

|

|

|

|

System |

Write Date & Time |

TW |

80 |

× |

|

|

x |

|

Read Date & Time |

TR |

81 |

× |

|

|

x |

|

|

Read version information |

VI |

82 |

× |

|

|

|

|

|

Write time zone |

TZW |

83 |

× |

|

× |

x |

|

|

Read time zone |

TZR |

84 |

× |

|

× |

x |

|

|

Fetch measurement results |

Fetch internal measurement values |

GR |

104 |

× |

|

× |

x |

|

Fetch measured values |

GM |

112 |

× |

|

× |

x |

|

|

Head-to-head Adjustment Execution |

Head-to-head Adjustment Execution |

HAE |

122 |

× |

× |

*5 |

x |

|

Image Composition |

Write image composition capture cycle |

ICCW |

128 |

x |

x |

|

x |

|

Read image composition capture cycle |

ICCR |

129 |

x |

|

|

x |

|

|

Simple Monitor View |

Change simple monitor view strings |

AIW |

- |

x |

|

|

x |

|

Obtain simple monitor view strings |

AIR |

- |

x |

|

|

x |

|

|

Setting change |

Write tool settings |

TSW |

130 |

x |

x |

|

x |

|

Read tool settings |

TSR |

131 |

x |

|

|

x |

|

|

Clear tool settings |

TSC |

132 |

x |

x |

|

x |

|

|

Head Adjustment |

Obtain optical axis state |

OASR |

136 |

x |

x |

|

x |

*1 In addition to running commands, functions can also be run by operating a bit device with assigned commands.

*2 Recipe numbers can also be changed by changing the recipe number area for the word device.

*3 Can be run from the input terminal.

*4 Can also be run from the input terminal.

*5 Execution is only possible after the head-to-head adjustment start command is issued.

*6 When switching to setup mode with another device, the commands from the previous device will be “Block”.

(Example) The commands from the PLC will be “Block” when using the PLC to control, but then switching [Setup] modes from the dedicated monitor (TM-MP120) or TM-X Navigator.

Trigger

T1: Issue Trigger

This command issues a trigger.

For non-procedural commands

- Send

T1 ![]() Issue a trigger

Issue a trigger

- Receive

T1 ![]()

For number-specified commands

The number-specified command No. is “1”.

- Send

|

Word Device |

* |

|

1 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

03 |

|

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

System control

Changes from setup mode to run mode. The operation will finish successfully even if it is executed in run mode.

For non-procedural commands

- Send

R0 ![]()

- Receive

R0 ![]()

For number-specified commands

The number-specified command No. is “8”.

- Send

|

Word Device |

* |

|

8 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

22 |

An unnecessary parameter is included. |

Real-time performance

Executes command data immediately.

This command switches from run mode to setup mode. The operation will finish successfully even if it is executed in setup mode.

For non-procedural commands

- Send

S0 ![]()

- Receive

S0 ![]()

For number-specified commands

The number-specified command No. is “9”.

- Send

|

Word Device |

* |

|

9 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

22 |

An unnecessary parameter is included. |

Real-time performance

If a tool is being executed, the command is executed after the tool completes execution.

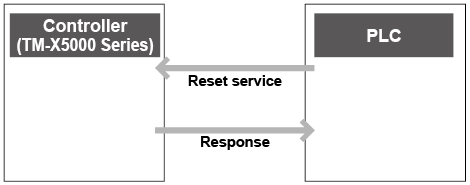

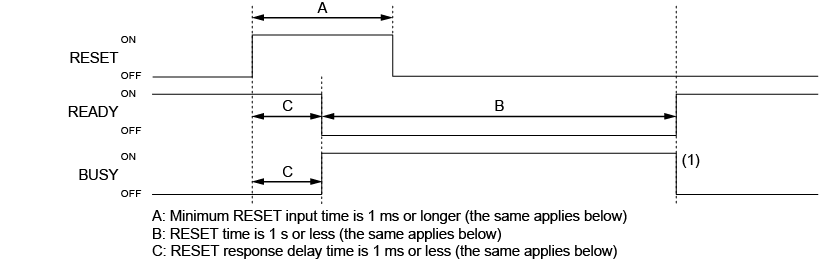

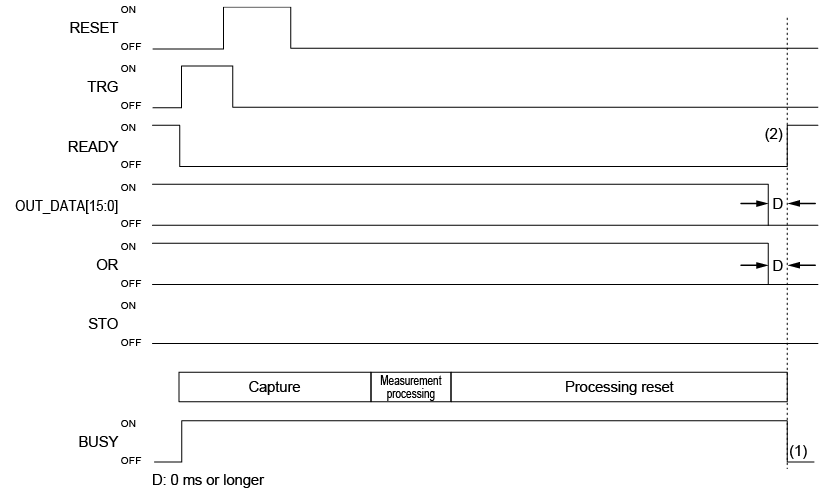

RS: Reset

This command performs all of the following:

- Clears all buffers including the image buffer.

- Creates a new file name for the file used to store data.

- Initializes total status output.

- Clears OUT_DATA0 to OUT_DATA15.

- Clears all of history data.

- Clears the measurement count.

For non-procedural commands

- Send

RS ![]()

- Receive

RS ![]()

For number-specified commands

The number-specified command No. is “10”.

- Send

|

Word Device |

* |

|

10 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

An unnecessary parameter is included. |

Real-time performance

If a tool is being executed, the command is executed after the tool completes execution.

RB: Reboot

This command saves the current program settings and reboots the system.

For non-procedural commands

- Send

RB ![]()

- Receive

RB ![]()

For number-specified commands

The number-specified command No. is “11”.

- Send

|

Word Device |

* |

|

11 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

An unnecessary parameter is included. |

Real-time performance

- If a tool is being executed, the command is executed after the tool completes execution.

- When data is being output, the process is synchronized according to the OE command timing, and then the command is executed.

This command saves the current program settings and global settings.

For non-procedural commands

- Send

SS ![]()

- Receive

SS ![]()

For number-specified commands

The number-specified command No. is “12”.

- Send

|

Word Device |

* |

|

12 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

03 |

|

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

This command clears the error status. Even when an error status does not exist, the command execution finishes normally.

For non-procedural commands

- Send

CE ![]()

- Receive

CE ![]()

For number-specified commands

The number-specified command No. is “13”.

- Send

|

Word Device |

* |

|

13 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

RM: Read Run/Setup Mode

This command reads the status of the controller (i.e. whether it is in run mode or setup mode).

For non-procedural commands

- Send

RM ![]()

- Receive

RM,n ![]()

For number-specified commands

The number-specified command No. is “16”.

- Send

|

Word Device |

* |

|

No. 16 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

Execution result |

n |

|||

* Starting word device (command result address)

Parameters (common)

|

n |

Controller status

|

Execution result

|

0 |

Success |

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

Change inspection program

This command closes all open dialogs and loads the program of the specified number (nnn) from the SD memory card.

- Any changes to the setting data is discarded.

- To retain the program number after changing programs, save the global setting file with the save program command (SS command).

For non-procedural commands

- Send

PW,d,nnn ![]()

- Receive

PW ![]()

For number-specified commands

The number-specified command No. is “24”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

|

24 |

d |

nnn |

||||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Parameters (common)

|

d |

SD memory card No. (1 or 2)

|

|

nnn |

Program No. (0 to 999) |

Execution result

|

0 |

Success |

|

03 |

|

|

22 |

The number or the range of the parameter is incorrect. |

Real-time performance

If a tool is being executed, the command is executed after the tool completes execution.

PR: Read Programs

This command reads the SD memory card number and the setting number of the program currently being read.

For non-procedural commands

- Send

PR ![]()

- Receive

PR,d,nnn ![]()

For number-specified commands

The number-specified command No. is “25”.

- Send

|

Word Device |

* |

|

25 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

|

Return value |

Execution result |

d |

nnn |

|||

* Starting word device (command result address)

Parameters (common)

|

d |

SD memory card No. (1 or 2)

|

|

nnn |

Program No. (0 to 999) |

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

Measurement control

This command changes to the specified recipe number.

For non-procedural commands

- Send

EXW,n ![]()

- Receive

EXW ![]()

For number-specified commands

The number-specified command No. is “41”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

41 |

n |

|||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Parameters (common)

|

n |

1 to 8 (Recipe No.) |

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

The number or the range of the parameter is incorrect. |

Real-time performance

The measurement processing time will not be affected.

EXR: Read Recipe No.

This command reads the active recipe number.

For non-procedural commands

- Send

EXR ![]()

- Receive

EXR,n ![]()

For number-specified commands

The number-specified command No. is “42”.

- Send

|

Word Device |

* |

|

42 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

Execution result |

n |

|||

* Starting word device (command result address)

Parameters (common)

|

n |

1 to 8 (Recipe No.) |

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

This command issues the timing input for the active recipe number.

For non-procedural commands

- Send

TIM ![]()

- Receive

TIM ![]()

For number-specified commands

The number-specified command No. is “52”.

- Send

|

Word Device |

* |

|

52 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

|

Real-time performance

The measurement processing time will not be affected.

This command issues an auto zero ON or OFF request for the active recipe number.

|

|

The auto zero value (the value that calibrates zero) is not saved. Run the save (SS) command as necessary. |

For non-procedural commands

- Send

ZR,m,t,nnn,…,nnn ![]()

- Receive

ZR ![]()

For number-specified commands

The number-specified command No. is “53”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

... |

||

|

53 |

m |

t |

nnn |

... |

nnn |

||||||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Parameters (common)

|

m |

|

|

t |

No. of tools subject to the command Specifying 0 makes all tools used with the active recipe number subject to the command. |

|

nnn |

ID of the tool subject to the command (200 to 299, 500 to 599) However, when t = 0 (all tools), this parameter does not need to be specified. |

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

The number or the range of the parameter is incorrect. (Error conditions when multiple tools are specified)

|

Real-time performance

The measurement processing time will not be affected.

This command requests to reset the measured value for the active recipe number.

For non-procedural commands

- Send

MSR ![]()

- Receive

MSR ![]()

For number-specified commands

The number-specified command No. is “54”.

- Send

|

Word Device |

* |

|

54 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

RSA: Reset Measured Value (All Templates)

This command requests to reset the measured value for all recipe numbers (including recipe numbers that are not active).

For non-procedural commands

- Send

RSA ![]()

- Receive

RSA ![]()

For number-specified commands

The number-specified command No. is “55”.

- Send

|

Word Device |

* |

|

55 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

I/O control

TE: Enable/disable trigger input

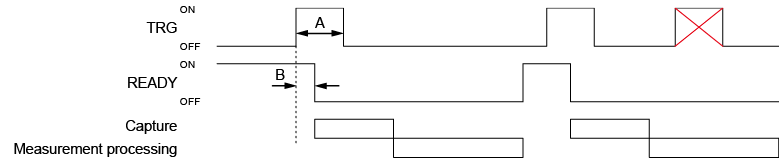

When “TE,0” is executed, the READY terminal is set to remain off and thus no trigger input will be accepted. When “TE,1” is executed, trigger input will be accepted.

Executing “TE,1” with the trigger enabled and “TE,0” with the trigger input disabled does not result in an error.

|

|

|

For non-procedural commands

- Send

TE,n ![]()

- Receive

TE ![]()

For number-specified commands

The number-specified command No. is “56”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

56 |

n |

|||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Parameters (common)

|

n |

|

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

The number or the range of the parameter is incorrect. |

Real-time performance

The measurement processing time will not be affected.

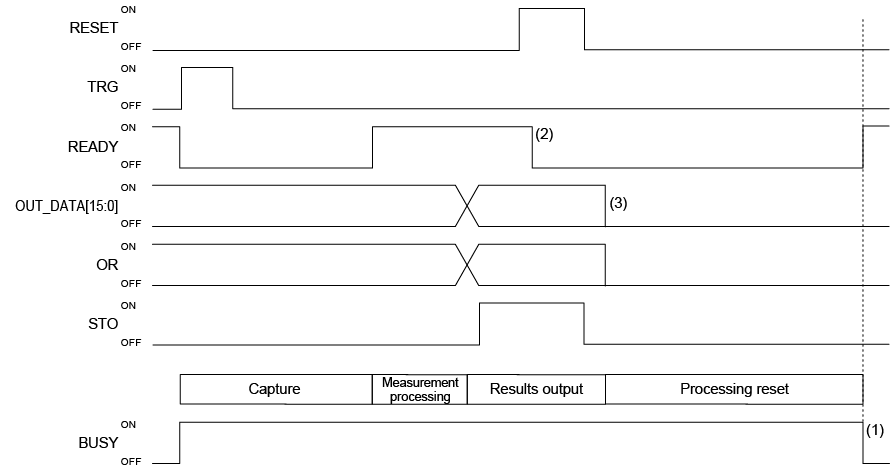

OE: Enable/disable output

This command disables the data/image output to the output buffer and clears the data in the buffer, so that data output to external devices is controlled.

Executing “OE,1” (enabled) when output is enabled and “OE,0” (disabled) when output is disabled does not result in an error.

This command controls the following output functions:

- Results output (terminal block, Ethernet, RS-232C, PLC-Link, EtherNet/IP, PROFINET, EtherCAT, SD card, USB HDD, FTP)

- Image output (SD card, USB HDD, FTP)

For non-procedural commands

- Send

OE,n ![]()

- Receive

OE ![]()

For number-specified commands

The number-specified command No. is “57”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

57 |

n |

|||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Parameters (common)

|

n |

|

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

The number or the range of the parameter is incorrect. |

Real-time performance

The measurement processing time will not be affected.

Details of command behavior when executed

Results output

- Output is aborted at the data unit set in results output (even if output is disabled during “one output of results,” that “one output of results” does not stop).

- If output is enabled, output is resumed the next time result output is possible (results when output is disabled will be not output and discarded).

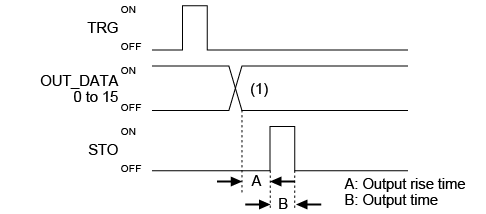

Terminal output

- Outputs to STO, OUT_DATA0 to 15, OR terminal blocks are immediately shut off and the state is set to normal.

- Even while output is disabled, the total status result of OR changes. However, such change is not applied to the terminal blocks.

- Even if STO and OUT_DATA0 to 15 output is disabled, the values do not change.

- For STO and OUT_DATA0 to 15, output is resumed at the next trigger execution (results when output is disabled will be not output and discarded).

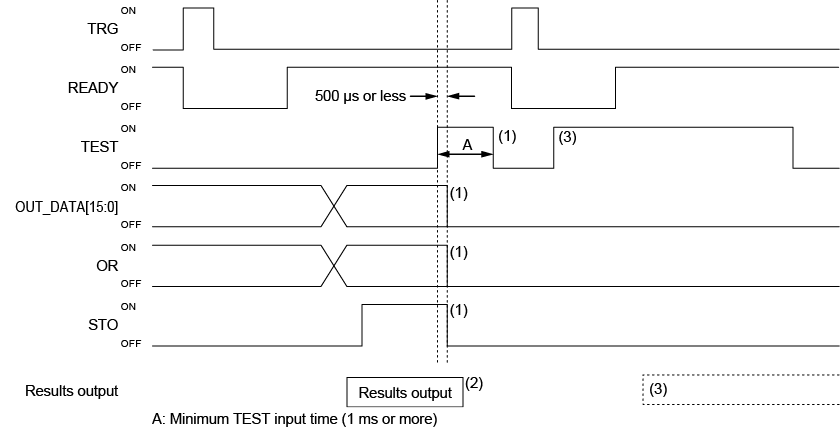

Relationship with TEST

- There is no priority setting between OE and TEST terminal. The latest status, enabled or disabled, is reflected to the internal operation.

(Example)

Inputting “OE,1” (enable) when TEST=ON (disable) enables output.

Then, specifying ON (disable) when TEST=OFF (enable) disables output.

- Output is enabled or disabled based on the status (level) of TEST immediately after the controller is turned on, reset, or the program is changed.

(Example)

Inputting “OE,1” (enable) when TEST=ON (disable) enables output.

Then, when the program is changed later, output is disabled when TEST=ON (disable).

Utility

STW: Replace the externally specified string

This command replaces the externally specified string.

For non-procedural commands

- Send

STW,n,”ssss ![]()

- Receive

STW ![]()

- Parameter

|

n |

To specify the externally specified string to be replaced (0 to 9) |

|

ssss |

The string used for replacement (number of characters 0 to 64) |

For number-specified commands

The number-specified command No. is “60”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

... |

|

60 |

n |

s1 |

s2 |

... |

|||||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

- Parameter

|

n |

To specify the externally specified string to be replace (0 to 9) |

|

ssss |

The string used for replacement (number of characters 0 to 64) In the send data, use two words for one character, the end code is 0 (zero). |

Execution result

|

0 |

Success |

|

03 |

When the externally specified string is not available (e.g. settings of old version) |

|

22 |

|

Real-time performance

Executes command data immediately.

STR: Read the externally specified string

This command reads the content of the externally specified string.

For non-procedural commands

- Send

STR,n ![]()

- Receive

STR,ssss ![]()

- Parameter

|

n |

To specify the externally specified string to be read (0 to 9) |

|

ssss |

The externally specified string (number of characters 0 to 64) |

For number-specified commands

The number-specified command No. is “61”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

61 |

n |

|||

* Starting word device (command address)

- Receive

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

... |

|

Execution result |

s1 |

s2 |

s3 |

... |

|||||

* Starting word device (command result address)

- Parameter

|

n |

To specify the externally specified string to be read (0 to 9) |

|

ssss |

The externally specified string (number of characters 0 to 64) In the receive data, use two words for one character, the end code is 0 (zero). |

Execution result

|

0 |

Success |

|

03 |

When the externally specified string is not available (e.g. settings of old version) |

|

22 |

|

Real-time performance

Executes command data immediately.

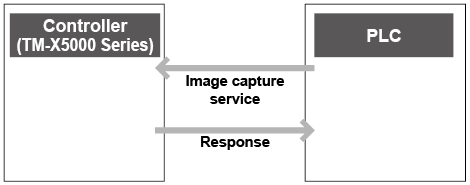

HC: Clear Archived Images

This command clears the archived images.

For non-procedural commands

- Send

HC ![]()

- Receive

HC ![]()

For number-specified commands

The number-specified command No. is “66”.

- Send

|

Word Device |

* |

|

66 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

This command changes the output file/folder.

- When changing a data output file, a new result file is created using the latest date and time.

- When changing an image output folder, a new image output folder is created using the latest date and time.

- When changing a simple monitor image output folder, a new simple monitor image output folder is created using the latest date and time.

For non-procedural commands

- Send

OW,n ![]()

- Receive

OW ![]()

For number-specified commands

The number-specified command No. is “69”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

69 |

n |

|||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Parameters (common)

|

n |

Select the target for changing

|

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

The number or the range of the parameter is incorrect. |

Real-time performance

Executes command data immediately.

EC: Echo

This command returns the same character string as the one that was sent from the external device.

|

|

The number-specified commands cannot be used. |

For non-procedural commands

- Send

EC,ssss ![]()

- Receive

EC,ssss ![]()

Parameter

|

ssss |

String Character string of 128 characters or less consisting of alphabets and numbers |

Execution result

|

0 |

Success |

|

22 |

|

Real-time performance

The measurement processing time will not be affected.

System

TW: Write Date/Time

This command sets the date and time of the controller.

For non-procedural commands

- Send

TW,yy,mo,dd,hh,mi,ss ![]()

TW,yyyy,mo,dd,hh,mi,ss ![]()

- Receive

TW ![]()

For number-specified commands

The number-specified command No. is “80”.

- Send

|

Word device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

*+8 |

*+9 |

*+10 |

*+11 |

*+12 |

*+13 |

|

80 |

yy |

mo |

dd |

hh |

mi |

ss |

||||||||

|

Word device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

*+8 |

*+9 |

*+10 |

*+11 |

*+12 |

*+13 |

|

80 |

yyyy |

mo |

dd |

hh |

mi |

ss |

||||||||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Parameters (common)

|

yy |

Year (0 to 99, lower two digits of the western calendar (20 for 2020)) When 00 to 99 is specified, 2000 will be added to the value before processing. |

|

yyyy |

Year (2000 to 2099) |

|

mo |

Month (1 to 12) |

|

dd |

Day (1 to 31) |

|

hh |

Hour (0 to 23) NB: 24-hour format |

|

mi |

Minutes (0 to 59) |

|

ss |

Seconds (0 to 59) |

Execution result

|

0 |

Success |

|

03 |

|

|

22 |

The number or the range of the parameter is incorrect. |

Real-time performance

The measurement processing time will not be affected.

TR: Read date/time

This command reads the current date and time on the controller.

For non-procedural commands

- Send

TR ![]()

- Receive

TR,yy,mo,dd,hh,mi,ss ![]()

For number-specified commands

The number-specified command No. is “81”.

- Send

|

Word Device |

* |

|

81 |

* Starting word device (command address)

- Receive

|

Word device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

*+8 |

*+9 |

*+10 |

*+11 |

*+12 |

*+13 |

|

Return value |

Execution result |

yy |

mo |

dd |

hh |

mi |

ss |

|||||||

* Starting word device (command result address)

Parameters (common)

|

yy |

Year (0 to 99, lower two digits of the western calendar (20 for 2020)) |

|

mo |

Month (1 to 12) |

|

dd |

Day (1 to 31) |

|

hh |

Hour (0 to 23) NB: 24-hour format |

|

mi |

Minutes (0 to 59) |

|

ss |

Seconds (0 to 59) |

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

VI: Read Version Information

This command reads the controller system information (model number and ROM version).

For non-procedural commands

- Send

VI ![]()

- Receive

VI, nnnn, vvvv ![]()

- Parameter

|

nnnn |

Model string (e.g.) TM-X5000 |

|

vvvv |

ROM version (14-character string) |

|

|

The following is an example of the version that is displayed when the controller system information is x.y.zzzz: VI,TM-X5000,000x.000y,zzzz |

For number-specified commands

The number-specified command No. is “82”.

- Send

|

Word Device |

* |

|

82 |

* Starting word device (command address)

- Receive

|

Word device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

*+8 |

*+9 |

*+10 |

*+11 |

|

Return value |

Execution result |

nn |

r |

hw |

mj |

mn |

||||||

* Starting word device (command result address)

- Parameter

|

nn |

Model number (4-digits) |

|

r |

Reserved area (always 0) |

|

hw |

Indicates the first digit of the major version in the ROM version information as a number. |

|

mj |

Indicates the second digit of the major version in the ROM version information as a number. |

|

mn |

Indicates the minor version in the ROM version information as a number. |

|

|

The following is an example when the version displayed on the UI is x.y.zzzz. (When the beginning of the command result address is DM0)

|

||||||||||||||||||||||||||||||||

Execution result

|

0 |

Success |

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

TZW: Write Time Zone

This command sets the SNTP time zone.

|

|

The time zone will not be saved even if this command is used. To save it, run the save settings (SS) command. |

For non-procedural commands

- Send

TZW,n ![]()

- Receive

TZW ![]()

For number-specified commands

The number-specified command No. is “83”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

83 |

n |

|||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Parameters (common)

|

n |

Time zone (0 to 33) |

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

The number or the range of the parameter is incorrect. |

Real-time performance

The measurement processing time will not be affected.

TZR: Read Time Zone

This command reads the SNTP time zone.

For non-procedural commands

- Send

TZR ![]()

- Receive

TZR,n ![]()

For number-specified commands

The number-specified command No. is “84”.

- Send

|

Word Device |

* |

|

84 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

Execution result |

n |

|||

* Starting word device (command result address)

Parameters (common)

|

n |

Time zone (0 to 33) |

Execution result

|

0 |

Success |

|

03 |

When the command was issued in Setup mode. |

|

22 |

An unnecessary parameter is included. |

Real-time performance

The measurement processing time will not be affected.

Fetching Measurement Results

GR: Fetch Internal Measurement Values

This command fetches the internal measurement values for the latest image.

For non-procedural commands

- Send

GR,t,nnn,…,nnn ![]()

- Receive

GR,t,m,…,m ![]()

For number-specified commands

The number-specified command No. is “104”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

... |

|

|

104 |

t |

nnn |

... |

nnn |

||||

* Starting word device (command address)

- Receive

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

... |

|

|

Return value |

Execution result |

t |

m |

... |

m |

|||

* Starting word device (command result address)

Parameters (common)

|

t |

No. of tools subject to fetching (t ≤ 12, all tools when 0 is specified) |

|

nnn |

ID of the tool subject to fetching (200 to 299, 500 to 599) |

|

m |

Internal measurement value |

Execution result

|

0 |

Success |

|

03 |

|

|

22 |

|

Real-time performance

The measurement processing time will not be affected.

GM: Fetch Measured Values

This command fetches measured values and judgment results.

For non-procedural commands

- Send

GM,o,t,nnn,…,nnn ![]()

- Receive

When o = 0 GM,t,m,…,m ![]()

When o = 1 GM,t,m,i,…,m,i ![]()

When o = 2 GM,t,m,j,…,m,j ![]()

When o = 3 GM,t,m,i,j,…,m,i,j ![]()

For number-specified commands

The number-specified command No. is “112”.

- Send

|

Word device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

... |

|

|

112 |

o |

t |

nnn |

... |

nnn |

|||||

* Starting word device (command address)

- Receive

When o = 0

|

Word device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

... |

|

|

Return value |

Execution result |

t |

m |

... |

m |

|||

When o = 1

|

Word device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

... |

||

|

Return value |

Execution result |

t |

m |

i |

... |

m |

i |

||||

When o = 2

|

Word device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

... |

||

|

Return value |

Execution result |

t |

m |

j |

... |

m |

j |

||||

When o = 3

|

Word device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

*+8 |

*+9 |

... |

|||

|

Return value |

Execution result |

t |

m |

i |

j |

... |

m |

i |

j |

|||||

* Starting word device (command result address)

Parameters (common)

|

o |

Output items (0: Measured value only, 1: Measured value + measurement result information, 2: Measured value + judgment result, 3: Measured value + measurement result information + judgment result) |

|

t |

No. of tools subject to fetching (t ≤ 12, all tools when 0 is specified) |

|

nnn |

ID of the tool subject to fetching (200 to 299, 500 to 599) |

|

m |

Measured value |

|

i |

Measurement result information (0: Unexecuted, 1: Normal value, 2: Position adjustment failure, 3: Invalid data, 4: Judgment standby data) |

|

j |

Judgment result (0: OK, 1: NG) |

Execution result

|

0 |

Success |

|

03 |

|

|

22 |

|

Real-time performance

The measurement processing time will not be affected.

Head-to-head Adjustment Execution

HAE: Head-to-head Adjustment Execution

Executes head-to-head adjustment.

|

|

This command can be used only in setup mode. To switch between setup and run mode, use S0/R0 command accordingly. |

For non-procedural commands

- Send

HAE ![]()

- Receive

HAE,n,x,y,t ![]()

For number-specified commands

The number-specified command No. is “122”.

- Send

|

Word Device |

* |

|

122 |

* Starting word device (command address)

- Receive

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

*+8 |

*+9 |

|

Return value |

Execution result |

n |

x |

y |

t |

|||||

* Starting word device (command result address)

Parameters (common)

|

n |

Head-to-head adjustment result

|

|

x |

Position alignment result x (The value is -99999.9999 if the operation fails) |

|

y |

Position alignment result y (The value is -99999.9999 if the operation fails) |

|

t |

Position alignment result θ (The value is -99999.9999 if the operation fails) |

Execution result

|

0 |

Success |

|

03 |

|

|

22 |

An unnecessary parameter is included. |

Real-time performance

If a tool is being executed, the command is executed after the tool completes execution.

Image Composition

ICCW: Write image composition capture cycle

This command changes the current image composition capture cycle to a specified value.

When the specified capture cycle is shorter than the capture time, the capture time will be set as the cycle.

|

|

This command can be used only in setup mode. To switch between setup and run mode, use S0/R0 command accordingly. This command can only be used with dark or bright image composition. |

For non-procedural commands

- Send

ICCW,n,m ![]()

- Receive

ICCW ![]()

For number-specified commands

The number-specified command No. is “128”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

|

128 |

n |

m |

||||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Parameters (common)

|

n |

Head number (0: Head A, 1: Head B) |

|

m |

Image capture cycle (0 to 10000 µsec) |

Execution result

|

03 |

When the image composition of the specified head is not dark/bright composition. |

|

22 |

The number or the range of the parameter is incorrect. |

Real-time performance

If a tool is being executed, the command is executed after the tool completes execution.

ICCR: Read image composition capture cycle

This command reads the current image composition capture cycle.

This command can only be used with dark or bright image composition.

For non-procedural commands

- Send

ICCR,n ![]()

- Receive

ICCR,m ![]()

For number-specified commands

The number-specified command No. is “129”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

129 |

n |

|||

* Starting word device (command address)

- Receive

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

Execution result |

m |

|||

* Starting word device (command result address)

Parameters (common)

|

n |

Head number (0: Head A, 1: Head B) |

|

m |

Image capture cycle (0 to 10000 µsec) |

Execution result

|

03 |

When the image composition of the specified head is not dark/bright composition. |

|

22 |

The number or the range of the parameter is incorrect. |

Real-time performance

The measurement processing time will not be affected.

Simple Monitor View

AIW: Change simple monitor view strings

Sets the string to be displayed on the simple monitor screen.

|

|

The number-specified commands cannot be used. |

For non-procedural commands

- Send

AIW,m,N1,S1,…,Nm,Sm ![]()

- Receive

AIW ![]()

Parameter

|

m |

Number of lines of strings that configure the settings (1 to 10) A line number and string set is 1. |

|

N1 to Nm |

Line number (1 to 10) If the same line number is set multiple times, the last settings are enabled. |

|

S1 to Sm |

Content of a string to be set in the line specified with N ASCII characters, with the exception of a semi-colon (;) and comma (,) can be used. If a string is not specified, the string on the applicable line number is deleted. |

Execution result

|

0 |

Success |

|

22 |

The number or the range of the parameter is incorrect.

|

Real-time performance

Executes command data immediately.

AIR: Obtain simple monitor view strings

Obtains the string to be displayed on the simple monitor screen.

|

|

The number-specified commands cannot be used. |

For non-procedural commands

- Send

AIR,m,N1,…,Nm ![]()

- Receive

AIR,m,N1,S1,…,Nm,Sm ![]()

Parameter

|

m |

Number of lines to be obtained (1 to 10) |

|

N1 to Nm |

Line number (1 to 10) |

|

S1 to Sm |

Content of the string in the line indicated by N |

Execution result

|

0 |

Success |

|

03 |

The string could not be obtained. |

|

22 |

The parameter range is incorrect |

Real-time performance

Executes command data immediately.

Setting change

This command writes upper limit and lower limit in the tolerance settings of the specified tool.

|

|

This command can be used only in setup mode. To switch between setup and run mode, use S0/R0 command accordingly. |

For non-procedural commands

- Send

TSW,nnn,i,m ![]()

- Receive

TSW ![]()

For number-specified commands

The number-specified command No. is “130”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

|

130 |

nnn |

i |

m |

|||||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

|

|

For the number-specified commands, specify integer data when using fixed-point as the decimal point. (Example) To write 12.345, specify 12345. However, if the number has 3 or more digits after the decimal point, use floating-point. |

Parameters (common)

|

nnn |

ID of the tool subject to the command (200 to 399, 500 to 699) |

|

i |

Item ID (0: lower value, 1: upper value) |

|

m |

Setting value (Effective value: -100,000,000 to 100,000,000) |

Execution result

|

0 |

Success |

|

03 |

|

|

22 |

|

Real-time performance

If a tool is being executed, the command is executed after the tool completes execution.

This command reads upper limit and lower limit in the tolerance settings of the specified tool.

For non-procedural commands

- Send

TSR,nnn,i ![]()

- Receive

TSR,s,m ![]()

For number-specified commands

The number-specified command No. is “131”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

|

131 |

nnn |

i |

||||

* Starting word device (command address)

- Receive

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

|

Return value |

Execution result |

s |

m |

|||

* Starting word device (command result address)

|

|

For the number-specified commands, the value will be read without decimal point when using fixed-point as the decimal point. (Example 1) When 12.3456 is read, the data will be an integer value, which is 123456. (Example 2) When 1.234 is read, the data will be an integer value, which is 1234. |

Parameters (common)

|

nnn |

ID of the tool subject to the command (200 to 399, 500 to 699) |

|

i |

Item ID (0: lower value, 1: upper value) |

|

s |

When the item ID is 0 or 1

|

|

m |

Setting value (Effective value: -100,000,000 to 100,000,000) When the item ID is 0 or 1, and the tolerance have not been set, 0 will be returned. |

Execution result

|

0 |

Success |

|

22 |

|

Real-time performance

The measurement processing time will not be affected.

This command clears upper limit and lower limit in the tolerance settings of the specified tool.

|

|

This command can be used only in setup mode. To switch between setup and run mode, use S0/R0 command accordingly. |

For non-procedural commands

- Send

TSC,nnn,i ![]()

- Receive

TSC ![]()

For number-specified commands

The number-specified command No. is “132”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

|

132 |

nnn |

i |

||||

* Starting word device (command address)

- Receive

|

Word Device |

* |

|

Return value |

Execution result |

* Starting word device (command result address)

Parameters (common)

|

nnn |

ID of the tool subject to the command (200 to 399, 500 to 699) |

|

i |

Item ID (0: lower value, 1: upper value) |

Execution result

|

0 |

Success |

|

03 |

|

|

22 |

|

Real-time performance

If a tool is being executed, the command is executed after the tool completes execution.

Head Adjustment

OASR: Obtain optical axis state

This command obtains optical axis state.

|

|

This command can be used only in setup mode. To switch between setup and run mode, use S0/R0 command accordingly. |

For non-procedural commands

- Send

OASR,n ![]()

- Receive

OASR,m,x,y ![]()

For number-specified commands

The number-specified command No. is “136”.

- Send

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

|

136 |

n |

|||

* Starting word device (command address)

- Receive

|

Word Device |

* |

*+1 |

*+2 |

*+3 |

*+4 |

*+5 |

*+6 |

*+7 |

|

Return value |

Execution result |

m |

x |

y |

||||

* Starting word device (command result address)

|

|

For the number-specified commands, the value will be 1/10000 when using fixed-point as the decimal point. (Example) When X=12345 is read, the value of X will be 1.2345. |

Parameters (common)

|

n |

Head number (0: Head A, 1: Head B) |

|

m |

Optical axis state (0: OK, 1: center point is not at correct location, 2: too many pixels with insufficient light) |

|

x |

Illumination center X-Position |

|

y |

Illumination center Y-Position |

|

|

If the obtained values of X and Y are in the circle of radius 10, the state is OK. |

Execution result

|

0 |

Success |

|

03 |

|

|

22 |

|

Real-time performance

If a tool is being executed, the command is executed after the tool completes execution.

Input/Output and Control Using EtherNet/IP

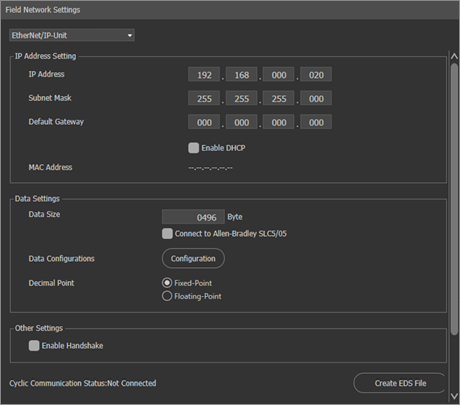

This system supports communication via EtherNet/IP.

EtherNet/IP is an open communications standard with specifications that are managed by ODVA (Open Device Net Vendor Association, Inc.). Communication is possible with all devices that support it, regardless of the vendor.

The following functions are possible by EtherNet/IP connection.

|

|

EtherNet/IP, PROFINET, EtherCAT, and PLC-Link cannot be used at the same time. |

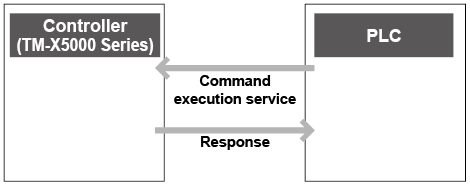

Cyclic Communication

Cyclic communication at RPI (Request Packet Interval) communication cycle intervals allows high-speed control at intervals of several ms to several tens of ms (implicit communication). In addition, because it is possible to control the controller by referencing and updating variables and devices in the PLC without considering the communication, it allows programs to be written easily on the PLC side.

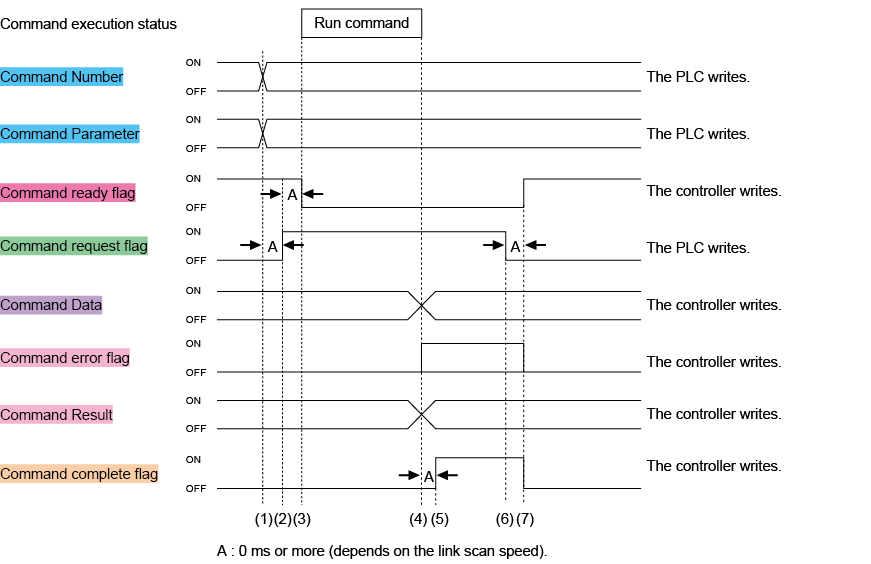

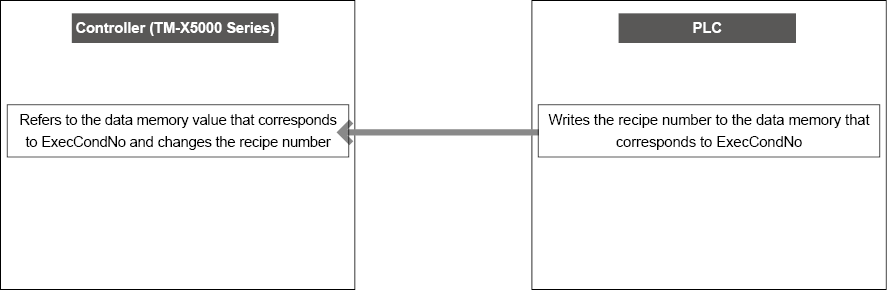

- Control the controller: The controller can be controlled by using cyclic communication to send the commands for execution.

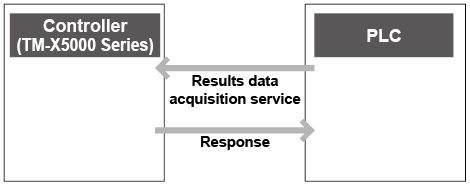

- Output the results data: Data can be output by cyclic communication when the items for output from EtherNet/IP are set in the output settings (Detail).

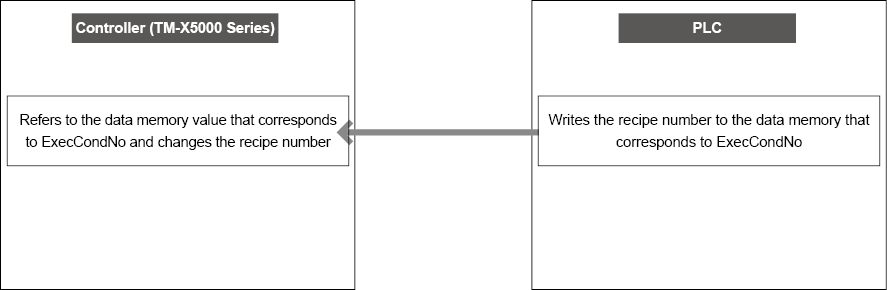

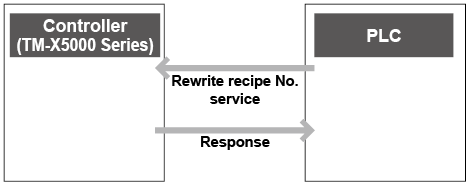

- Change the recipe number: The controller can be controlled by using cyclic communication to specify the recipe number.

|

|

|

Message Communication

This can be used for communications that do not require punctuality as is needed with cyclic communications (Explicit message).

There is no functional difference between the controller message communication function and cyclic communication function. As a result, it is not necessary to use it in most cases. However, it can be used for EtherNet/IP communications with PLC devices that do not support cyclic communication (SLC5/05 Series, etc.).

Controller EtherNet/IP Communication Specifications

Standard specifications

|

Controller Ethernet port |

Communication expansion unit (CB-NEP20E) |

||

|

Cyclic communication*1 (Implicit communication) |

Connection count |

Max. 32 |

1 (Exclusive Owner) 4 (Input Only) |

|

Communication size |

As set in the communications settings on the PLC side. Up to 248 bytes (when the Rockwell SLC5/05 is connected) Up to 496 bytes (when the Rockwell ControlLogix/CompactLogix is connected) Up to 1436 bytes (when the Keyence KV Series or Omron SYSMAC CJ2/CJ1/CS1/NJ is connected) |

||

|

Send trigger |

As set in the communications settings on the PLC side.

|

||

|

Instance ID |

|

|

|

|

Message communication (Explicit message) |

Connection count |

Max. 32 |

Max. 6 |

|

Supported Explicit message type |

UCMM/Class3 |

||

|

Conformance test |

Compliant with Version.CT17 |

||

|

*1: The condition for the cyclic communication status to become [Connected] is when either an Exclusive Owner or Input Only connection is established via the controller’s Ethernet port and only when an Exclusive Owner connection is established for the communication expansion unit. *2: Only a PLC that supports COS (such as Keyence KV-3000/5000/5500/7300/7500/8000 and the KV Nano Series) can be specified. When a COS send trigger is selected, the controller sends data at the time when a change in the data to be sent occurs. (If there is no change in the data to be sent, then data is sent at intervals of the specified RPI (communications cycle)). If the data to be sent continuously changes, data sending is delayed for the InhibitTime (minimum sending interval). Moreover, the part of the data that is subject to modification checks are “Result ready flag” and “Command complete flag” in the case of the controller’s Ethernet port and all data to be sent in the case of the communication expansion unit. |

|||

When to use message communication and cyclic communication

There is no functional difference between the controller message communication function and cyclic communication function. It is used for EtherNet/IP communications with PLC devices that do not support cyclic communication (SLC5/05 Series, etc.).

|

|

|

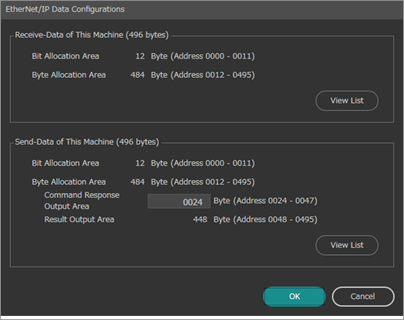

Allocation Conditions of Cyclic Communication Data

Example of the send-data settings for this controller (TM-X5000 Series to KV-7000 Series)

Example when 1 TM-X5000 series is connected to a KV-7000 Series, cyclic communication data size is 496 bytes (addresses 0000 - 0495), and the command response output area is set to 24 bytes (B****/W**** in the table are examples of KV-7000 link relay and link register address allocation)

|

Setting condition |

Address (byte) |

7bit |

6bit |

5bit |

4bit |

3bit |

2bit |

1bit |

0bit |

||||||||

|

Bit area |

0000 |

B007 |

Reserved |

B006 |

Reserved |

B005 |

Reserved |

B004 |

Result OR |

B003 |

Result Ready |

B002 |

Cmd Ready |

B001 |

Cmd Error |

B000 |

Cmd Complete |

|

0001 |

B00F |

MSR_VALID |

B00E |

RUN |

B00D |

Reserved |

B00C |

ERROR |

B00B |

BUSY |

B00A |

Reserved |

B009 |

TRG_ack |

B008 |

READY |

|

|

0002 |

B017 |

Reserved |

B016 |

Reserved |

B015 |

RESET_ALL_ack |

B014 |

MSR_RESET_ack |

B013 |

ZERO_OFF_ack |

B012 |

ZERO_ON_ack |

B011 |

Reserved |

B010 |

TIMING_ack |

|

|

0003 |

B01F |

Reserved |

B01E |

Reserved |

B01D |

Reserved |

B01C |

Reserved |

B01B |

Reserved |

B01A |

Reserved |

B019 |

Reserved |

B018 |

Reserved |

|

|

0004 |

B027 |

Tool Judge Value7 |

B026 |

Tool Judge Value6 |

B025 |

Tool Judge Value5 |

B024 |

Tool Judge Value4 |

B023 |

Tool Judge Value3 |

B022 |

Tool Judge Value2 |

B021 |

Tool Judge Value1 |

B020 |

Tool Judge Value0 |

|

|

0005 |

B02F |

Tool Judge Value15 |

B02E |

Tool Judge Value14 |

B02D |

Tool Judge Value13 |

B02C |

Tool Judge Value12 |

B02B |

Tool Judge Value11 |

B02A |

Tool Judge Value10 |

B029 |

Tool Judge Value9 |

B028 |

Tool Judge Value8 |

|

|

0006 |

B037 |

Tool Judge Value23 |

B036 |

Tool Judge Value22 |

B035 |

Tool Judge Value21 |

B034 |

Tool Judge Value20 |

B033 |

Tool Judge Value19 |

B032 |

Tool Judge Value18 |

B031 |

Tool Judge Value17 |

B030 |

Tool Judge Value16 |

|

|

0007 |

B03F |

Tool Judge Value31 |

B03E |

Tool Judge Value30 |

B03D |

Tool Judge Value29 |

B03C |

Tool Judge Value28 |

B03B |

Tool Judge Value27 |

B03A |

Tool Judge Value26 |

B039 |

Tool Judge Value25 |

B038 |

Tool Judge Value24 |

|

|

0008 |

B047 |

Tool Judge Value39 |

B046 |

Tool Judge Value38 |

B045 |

Tool Judge Value37 |

B044 |

Tool Judge Value36 |

B043 |

Tool Judge Value35 |

B042 |

Tool Judge Value34 |

B041 |

Tool Judge Value33 |

B040 |

Tool Judge Value32 |

|

|

0009 |

B04F |

Tool Judge Value47 |

B04E |

Tool Judge Value46 |

B04D |

Tool Judge Value45 |

B04C |

Tool Judge Value44 |

B04B |

Tool Judge Value43 |

B04A |

Tool Judge Value42 |

B049 |

Tool Judge Value41 |

B048 |

Tool Judge Value40 |

|

|

0010 |

B057 |

Tool Judge Value55 |

B056 |

Tool Judge Value54 |

B055 |

Tool Judge Value53 |

B054 |

Tool Judge Value52 |

B053 |

Tool Judge Value51 |

B052 |

Tool Judge Value50 |

B051 |

Tool Judge Value49 |

B050 |

Tool Judge Value48 |

|

|

0011 |

B05F |

Tool Judge Value63 |

B05E |

Tool Judge Value62 |

B05D |

Tool Judge Value61 |

B05C |

Tool Judge Value60 |

B05B |

Tool Judge Value59 |

B05A |

Tool Judge Value58 |

B059 |

Tool Judge Value57 |

B058 |

Tool Judge Value56 |

|

|

Error code area |

0012 |

W000 |

Error Code |

||||||||||||||

|

0013 |

|||||||||||||||||

|

Reserved area |

0014 |

W001 |

Reserved |

||||||||||||||

|

0015 |

|||||||||||||||||

|

Measurement count area |

0016 |

W002 |

Total Count |

||||||||||||||

|

0017 |

|||||||||||||||||

|

0018 |

|||||||||||||||||

|

0019 |

|||||||||||||||||

|

Command output area |

0020 |

W004 |

Command Result |

||||||||||||||

|

0021 |

|||||||||||||||||

|

0022 |

|||||||||||||||||

|

0023 |

|||||||||||||||||

|

0024 |

W006 |

Command Data 1 |

|||||||||||||||

|

0025 |

|||||||||||||||||

|

0026 |

|||||||||||||||||

|

0027 |

|||||||||||||||||

|

0028 |

W008 |

Command Data 2 |

|||||||||||||||

|

0029 |

|||||||||||||||||

|

0030 |

|||||||||||||||||

|

0031 |

|||||||||||||||||

|

… |

… |

… |

|||||||||||||||

|

0044 |

W010 |

Command Data 6 |

|||||||||||||||

|

0045 |

|||||||||||||||||

|

0046 |

|||||||||||||||||

|

0047 |

|||||||||||||||||

|

Results output area |

0048 |

W012 |

Result Data 1 |

||||||||||||||

|

0049 |

|||||||||||||||||

|

0050 |

|||||||||||||||||

|

0051 |

|||||||||||||||||

|

0052 |

W014 |

Result Data 2 |

|||||||||||||||

|

0053 |

|||||||||||||||||

|

0054 |

|||||||||||||||||

|

0055 |

|||||||||||||||||

|

… |

… |

… |

|||||||||||||||

Name and behavior of input signals

|

Allocation area |

Name |

Remarks |

||

|

Bit area |

Cmd Complete |

Turns on when command processing is completed. |

||

|

Cmd Error |

Turns off when command processing is successful and on when command processing fails. |

|||

|

Cmd Ready |

Turns on when command processing can be accepted. |

|||

|

Result Ready |

Turns on when data transmission is completed. |

|||

|

Result OR |

Used to output the OR result for the judged value of tool specified in the output settings. |

|||

|

READY |

Turns on when trigger input can be accepted. |

|||

|

TRG_ack |

Turns on when the trigger input is accepted. Turns off when trigger input turns off. |

|||

|

BUSY |

Output during measurement processing or command processing. |

|||

|

ERROR |

Output while a dialog box is displayed on the screen when a system error occurs. For details on typical system errors, see On the [System] screen for [Global] (Detail), error output for SD memory card-related errors and so on can also be specified. |

|||

|

RUN |

Output when the controller is in Run mode. |

|||

|

MSR_VALID |

Turns on when the internal measurement values for all tools set with the active recipe are no longer in the judgment standby state. Turns off if measured values are finalized with TIMING or when internal measurement values are cleared with MSR_RESET. |

|||

|

TIMING_ack |

Turns on when the input timing is accepted. Turns off when the input timing is turned off. |

|||

|

ZERO_ON_ack |

Turns on when zero on input is accepted. Turns off when zero on input is turned off. |

|||

|

ZERO_OFF_ack |

Turns on when zero off input is accepted. Turns off when zero off input is turned off. |

|||

|

MSR_RESET_ack |

Turns on when reset measured value input is accepted. Turns off when reset measured value input is turned off. |

|||

|

RESET_ALL_ack |

Turns on when reset measured value (all recipes) input is accepted. Turns off when reset measured value (all templates) input is turned off. |

|||

|

Tool judgment area |

Tool Judge Value0 |

Returns the judgment value assigned to the bit allocation area (address 0004:bit0). |

||

|

Tool Judge Value1 |

Returns the judgment value assigned to the bit allocation area (address 0004:bit1). |

|||

|

. . . |

. . . |

|||

|

Tool Judge Value63 |

Returns the judgment value assigned to the bit allocation area (address 0011:bit7). |

|||

|

Error code area |

Error Code |

Contains error codes for causes of errors. |

||

|

Measurement count area |

Total Count |

Indicates the measurement count.

|

||

|

Command output area |

Command Result |

Indicates the command execution results. |

||

|

Command Data 1 |

Returns command execution results data 1. |

|||

|

Command Data 2 |

Returns command execution results data 2. |

|||

|

. . . |

. . . |

|||

|

Command Data 6 |

Returns command execution results data 6. |

|||

|

Results output area |

Result Data 1 |

Returns measurement results data 1. |

||

|

Result Data 2 |

Returns measurement results data 2. |

|||

|

. . . |

. . . |

Example of the receive-data settings for this controller (KV-7000 Series to TM-X5000 Series)

Example when one TM-X5000 Series model is connected to a KV-7000 Series model and cyclic communication data size is 496 bytes (addresses 0000 - 0495)

(B****/W**** in the table are examples of KV-7000 link relay and link register address allocation)

|

Setting condition |

Address (byte) |

7bit |

6bit |

5bit |

4bit |

3bit |

2bit |

1bit |

0bit |

||||||||

|

Bit area |

0000 |

B067 |

Reserved |

B066 |

Reserved |

B065 |

Reserved |

B064 |

Error reset request |

B063 |

Result ack |

B062 |

Reserved |

B061 |

Reserved |

B060 |

Cmd request |

|

0001 |

B06F |

Reserved |

B06E |

Reserved |

B06D |

Reserved |

B06C |

Reserved |

B06B |

Reserved |

B06A |

Reserved |

B069 |

Reserved |

B068 |

TRG |

|

|

0002 |

B077 |

Reserved |

B076 |

Reserved |

B075 |

Reserved |

B074 |

Reserved |

B073 |

Reserved |

B072 |

TEST |

B071 |

EXT |

B070 |

RESET |

|

|

0003 |

B07F |

Reserved |

B07E |

Reserved |

B07D |

RESET_ALL |

B07C |

MSR_RESET |

B07B |

ZERO_OFF |

B07A |

ZERO_ON |

B079 |

Reserved |

B078 |

TIMING |

|

|

0004 |

B087 |

Reserved |

B086 |

Reserved |

B085 |

Reserved |

B084 |

Reserved |

B083 |

Reserved |

B082 |

Reserved |

B081 |

Reserved |

B080 |

Reserved |

|

|

0005 |

B08F |

Reserved |

B08E |

Reserved |

B08D |

Reserved |

B08C |

Reserved |

B08B |

Reserved |

B08A |

Reserved |

B089 |

Reserved |

B088 |

Reserved |

|

|

0006 |

B097 |

Reserved |

B096 |

Reserved |

B095 |

Reserved |

B094 |

Reserved |

B093 |

Reserved |

B092 |

Reserved |

B091 |

Reserved |

B090 |

Reserved |

|

|

0007 |

B09F |

Reserved |

B09E |

Reserved |

B09D |

Reserved |

B09C |

Reserved |

B09B |

Reserved |

B09A |

Reserved |

B099 |

Reserved |

B098 |

Reserved |

|

|

0008 |

B0A7 |

Reserved |

B0A6 |

Reserved |

B0A5 |

Reserved |

B0A4 |

Reserved |

B0A3 |

Reserved |

B0A2 |

Reserved |

B0A1 |

Reserved |

B0A0 |

Reserved |

|

|

0009 |

B0AF |

Reserved |

B0AE |

Reserved |

B0AD |

Reserved |

B0AC |

Reserved |

B0AB |

Reserved |

B0AA |

Reserved |

B0A9 |

Reserved |

B0A8 |

Reserved |

|

|

0010 |

B0B7 |

Reserved |

B0B6 |

Reserved |

B0B5 |

Reserved |

B0B4 |

Reserved |

B0B3 |

Reserved |

B0B2 |

Reserved |

B0B1 |

Reserved |

B0B0 |

Reserved |

|

|

0011 |

B0BF |

Reserved |

B0BE |

Reserved |

B0BD |

Reserved |

B0BC |

Reserved |

B0BB |

Reserved |

B0BA |

Reserved |

B0B9 |

Reserved |

B0B8 |

Reserved |

|

|

Recipe No. |

0012 |

W0F2 |

ExecCondNo |

||||||||||||||

|

0013 |

|||||||||||||||||

|

0014 |

W0F3 |

Reserved |

|||||||||||||||

|

0015 |

|||||||||||||||||

|

Command input area |

0016 |

W0F4 |

Command number |

||||||||||||||

|

0017 |

|||||||||||||||||

|

0018 |

|||||||||||||||||

|

0019 |

|||||||||||||||||

|

0020 |

W0F6 |

Cmd Parameter1 |

|||||||||||||||

|

0021 |

|||||||||||||||||

|

0022 |

|||||||||||||||||

|

0023 |

|||||||||||||||||

|

0024 |

W0F8 |

Cmd Parameter2 |

|||||||||||||||

|

0025 |

|||||||||||||||||

|

0026 |

|||||||||||||||||

|

0027 |

|||||||||||||||||

|

0028 |

W0FA |

Cmd Parameter3 |

|||||||||||||||

|

0029 |

|||||||||||||||||

|

0030 |

|||||||||||||||||

|

0031 |

|||||||||||||||||

|

… |

… |

… |

|||||||||||||||

|

|

As ExecCondNo is only loaded by the controller when there are changes, the recipe number can also be overwritten by a command. |

Name and behavior of output signals

|

Allocation area |

Name |

Remarks |

|

Bit area |

Cmd request |

Requests command execution when rising from OFF to ON. |

|

Result ack |

Notifies of data acquisition when rising from OFF to ON. |

|

|

Error reset request |

Clears errors when rising from OFF to ON. |

|

|

TRG |

Starts capture (measurement) (leading edge synchronization). The input is accepted when READY is ON. |

|

|

RESET |

Used to reset operation.

|

|

|

EXT |