Measurement Sensors

Dimension Measurement

Displacement Measurement

3D Laser Scanners vs. 2D Laser Scanners

With the strides made in 3D scanner technologies, 3D scanners have become increasingly popular and more accessible, mainly due to their ability to scan a surface in all three dimensions and provide a detailed surface profile of the scanned object.

But does that mean we should say our goodbyes to 2D scanners? Of course not; 2D scanners are still very much in use, and there’s no reason for them to disappear from the market. In this article, we’ll discuss 2D vs 3D laser scanners and their different applications.

What are 3D Laser Scanners?

3D laser scanners are devices that capture data from the surface of the object to accurately digitize its shape in a three-dimensional format. Unlike CMMs, which rely on physical contact with the object, laser 3D scanners are capable of quickly collecting and storing measurement data, allowing faster and easier inspection and analysis.

3D laser scanners are also used to reverse engineer parts and components and assure adequate fit between parts and components—among many other things. However, there are many different types of 3D scanners suitable for various applications.

Most importantly, 3D laser scanners are a key part in manufacturing to check tolerances, inspect for defects, and analyze components to ensure all specs and quality requirements are met. These scanners are used in conjunction with several other devices to automate factories around the world.

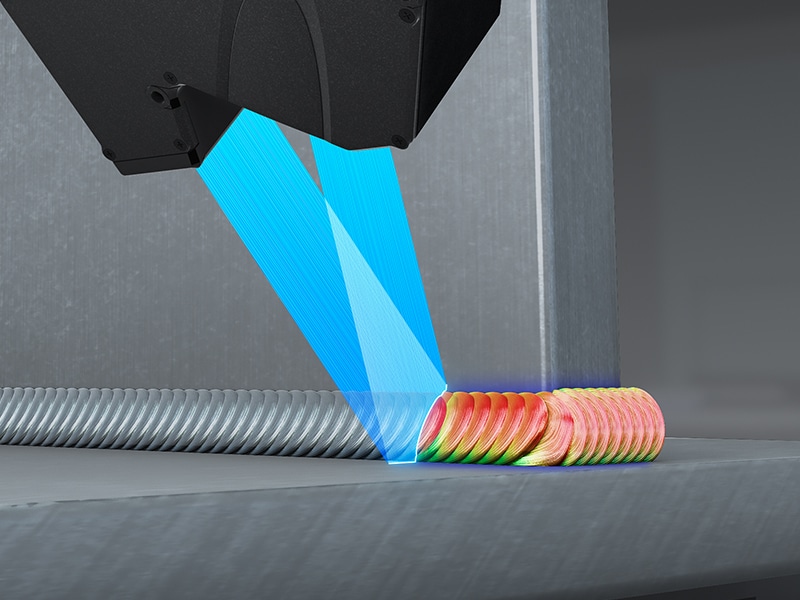

3D laser scanners use laser emitters and receivers to emit, collect, and interpret light but also rely on specialized software to record the changes in distance and shape of the laser line, resulting in a continuous collection of points along the XYZ axes and their corresponding coordinates.

What are 2D Laser Scanners?

2D laser scanners typically work by projecting a laser beam onto an object’s surface and detecting the light reflected into the measurement sensor. The working principles are the same as with 3D sensors, as they often involve laser triangulation which relies on the refraction angle to derive distance.

These devices are invaluable in dimensional measurement thanks to their high precision and accuracy, and they’re capable of capturing fine details and object contours for further processing. 2D laser scanners are critical for quality control, inspection, and reverse engineering processes.

Additionally, 2D laser scanners are incredibly versatile as they can be used on different materials and surface types, including metals, polymers, elastomers, wood, etc. They’re also easily integrated into larger automated systems for enhanced functionality, such as automated assembly lines or assembly robotics.

We’re here to provide you with more details.

Reach out today!

Applications for 3D Laser Scanners

Innovative 3D laser scanners are most commonly used in industrial design, engineering, and manufacturing, primarily because of quick and precise data capture—especially when compared to CMMs.

Thanks to their rapid data collection and processing, 3D laser scanners significantly accelerate the workflow, enhancing the productivity and reliability of your measurements. This makes 3D laser scanners invaluable in large-scale manufacturing, product design, testing, development, product launch, and subsequent support.

The applications for 3D laser scanners go beyond manufacturing, product design, and other activities associated with manufacturing industries. These measurement devices are now commonly used in the entertainment industry, forensic science, law enforcement, and medicine—for designing custom prosthetics and orthotics—and computer-generated imagery.

Applications for 2D Laser Scanners

While 3D laser scanners are generally a more advanced technology, they’re still not as widespread as 2D laser profile scanners, which, thanks to their ability to capture two-dimensional profiles, have found widespread use across various industries and applications.

Of course, industrial automation and manufacturing benefited the most from 2D laser scanners, which are most commonly used for inspection and quality control. These scanners ensure that all produced parts and components fit the desired dimensions and within the desired tolerances, ensuring that design specifications are met.

Discover more about this product.

Click here to book your demo.

Choosing the Best Laser Scanners

Several key factors should be considered when choosing the best laser scanner for your application, and that choice largely depends on your specific requirements. Here are some of the most important considerations:

Dimensional requirements

The most fundamental consideration when choosing between a 2D and 3D laser scanner is whether your application requires two-dimensional or three-dimensional data. 2D laser scanners are well-suited for measuring the length and width of objects, making them perfect for surface inspection, but 3D lasers provide more detailed information about the object’s geometrical properties.

Accuracy and resolution

Accuracy and resolution refer to the two different metrics; the former refers to tolerances, and the latter refers to the smallest of changes the scanner can pick up during a scan. 3D Scanners and 2D scanners provide similar accuracy and resolution; however they typically feature different models with ranges of specs.

Application-specific requirements

Certain applications may have requirements that make one type of scanner better suited. For example, detecting defects of a certain area/size demands the use of 3D scanners, while the speed and relative accuracy of 2D scanners maintain high-priority for simple height change and level checks.

Budget

Last but not least, the budget. 3D laser scanners are more expensive compared to 2D scanners, mainly due to the added comprehensiveness of data that has been generated and requirement for motion.

Curious about our pricing?

Click here to find out more.

Leveraging Laser Technology For Enhanced 3D Inspections

Laser snapshot technology like KEYENCE’s LJ-S8000 Series has revolutionized 3D inspections, and its ability to capture full 3D profiles in a single snapshot offers a very accurate representation of surfaces and objects compared to traditional scanning methods.

How Laser Snapshots Improve 3D Inspections in Industrial Applications

Laser snapshots are important in 3D inspections and can be applied in multiple ways across different industries. Some of the industrial applications of measurement sensors are in automotive, electronics, and manufacturing. 3D laser snapshot sensors capture depth and shape and can adapt to various surface variations in real time.

Snapshot sensors provide more comprehensive data, enabling manufacturers to quickly identify flaws and implement corrective actions. When applied well, they improve overall production efficiency and accuracy.

Laser Snapshot Sensors vs. 2D Laser Scanners

One major difference between a 3D laser snapshot sensor and a 2D scanner is their data acquisition process. 2D scanners gather data along a single line, which limits their effectiveness in a 3D world. Laser snapshot technology, however, completely captures even complex geometries, allowing industries to speed up their production process.

Another benefit of using laser snapshot sensors is their ability to capture data and defects with zero movement and minimal setup. This allows for quicker decision-making and problem-solving, reducing production downtime and costs.

Laser Snapshot Sensor Solutions for Advanced 3D Inspections

To meet the growing demand for high-precision inspections, KEYENCE’s laser snapshot technology offers significant advantages over traditional methods. These solutions deliver enhanced accuracy, speed, and versatility, making them ideal for advanced 3D inspections with laser sensors.

Ultimately, choosing a suitable laser scanner comes down to your particular application. If you’re unsure about which scanner best suits your needs, don’t hesitate to ask an expert—the industry leader’s team of experienced personnel will answer all the questions you might have about 2D and 3D scanners.

We’re here to provide you with more details.

Reach out today!

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity