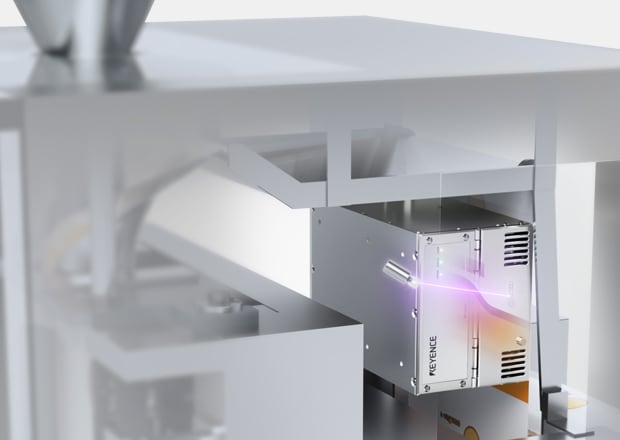

Cutting-Edge UV Laser Coding for the Consumer Products and Pharmaceuticals Industry

KEYENCE UV laser coding for the consumer products and pharmaceuticals film packaging industry offers crisp, durable marks without damaging the material. By eliminating consumables such as ink ribbons or specialty labels, these coders significantly lower operational expenses. Coder heads easily mount to a range of packaging machines, enabling smooth integration into existing production lines.

How UV Laser Coding Technology Works for the Consumer Products and Pharmaceuticals Industry

Laser coders for consumer products and pharmaceutical packaging are a top choice as they deliver precise, high-contrast marks on packaging materials like plastic and flexible film, without the need for ink or labels. Using a UV laser beam, they create legible codes, such as expiration dates and barcodes, even on heat-sensitive packaging, thanks to a low-heat, cold-marking process.

The KEYENCE FP-1000 Series UV laser coder is designed as a direct replacement for thermal transfer overprinters (TTO). Compact design and advanced features allow for permanent and flawless marks, even when there is oil, powder, or other contaminants on the surface of the film. As a result, you achieve uninterrupted operation, increased throughput, and eliminate the need for frequent part replacements or consumable costs.

UV lasers are not affected by traditional causes of marking that fades away:

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

We’re here to provide you with more details.

Reach out today!

Applications of UV Laser Coders in the Consumer Products and Pharmaceuticals Industry

UV laser markings on consumer products and pharmaceuticals packaging are common on plastic packaging for:

UV laser coders can also easily mark heat-sensitive materials like foil, films, cartons, and textile labels.

Granule package

Retort food pouch

Toothpaste tube

Alcohol container

Benefits of UV Laser Coding on Film in Consumer Products and Pharmaceutical Industries

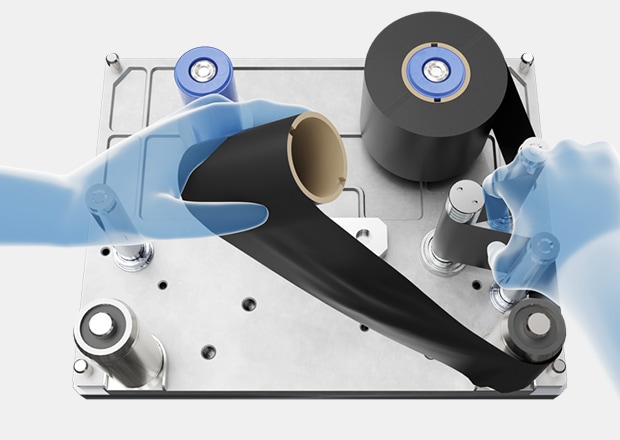

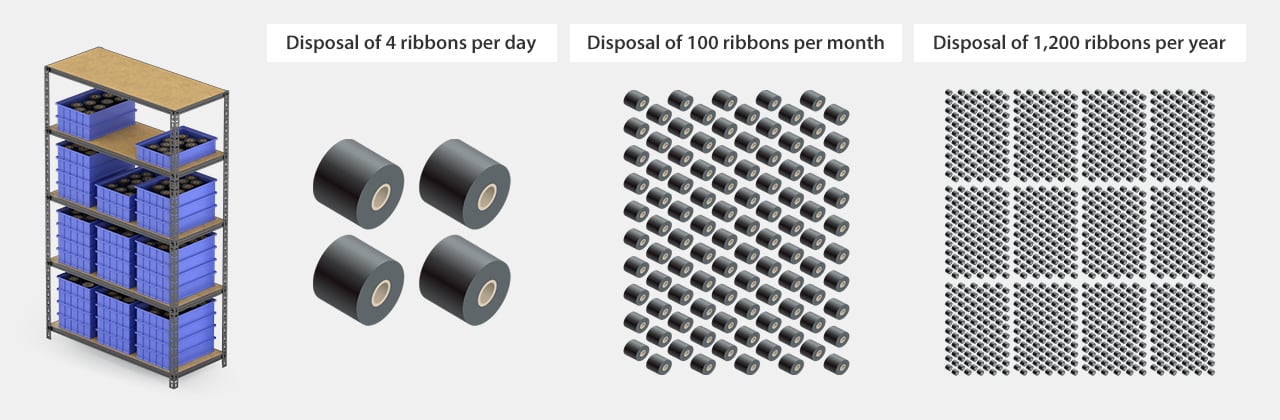

Eliminate Consumables

Because a UV laser coder relies on light for marking, there’s no need for regular part replacements, eliminating the use of consumables and eliminating related costs.

No ink ribbon costs

No head replacement costs

-

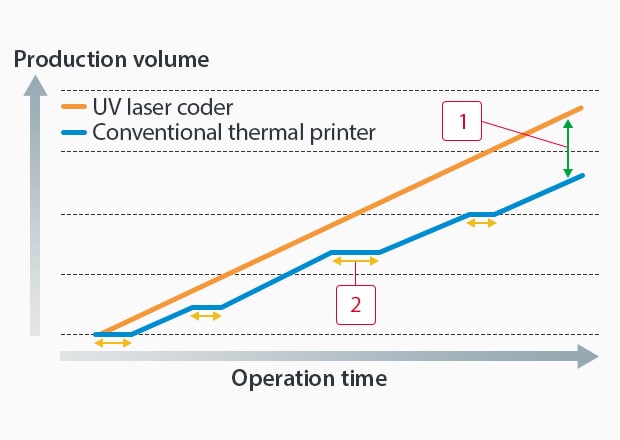

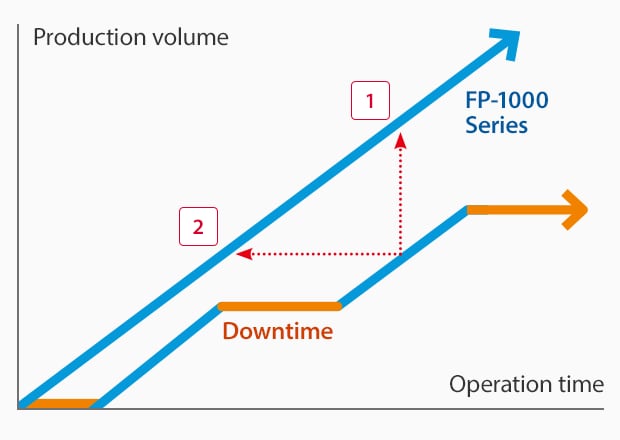

1UV laser coders can mark more products in the same operating time

-

2Downtime due to ink ribbon replacement and thermal head cleaning

Disposal loss simulation:

For a facility that replaces four ink ribbons per day, operating at 25 days per month will lead to disposal of 1,200 ink ribbons per year. At 500 grams 17.65 oz per ink ribbon, 1,200 ink ribbons would equal 600 kilograms 1322.76 lb, or about 1.2 tons of CO2 emissions upon disposal. UV laser coders, however, do not use ink ribbons, so the CO2 emissions can be reduced to zero.

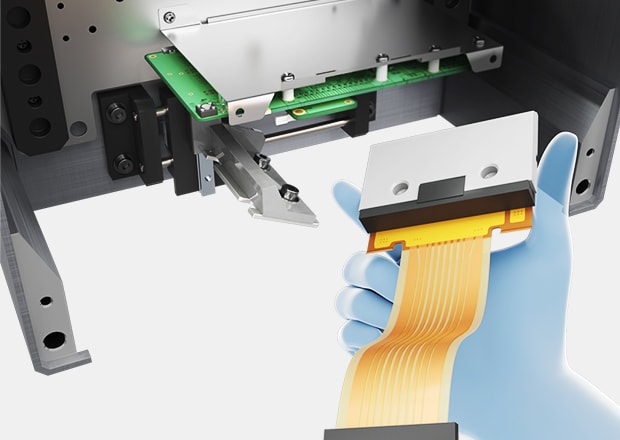

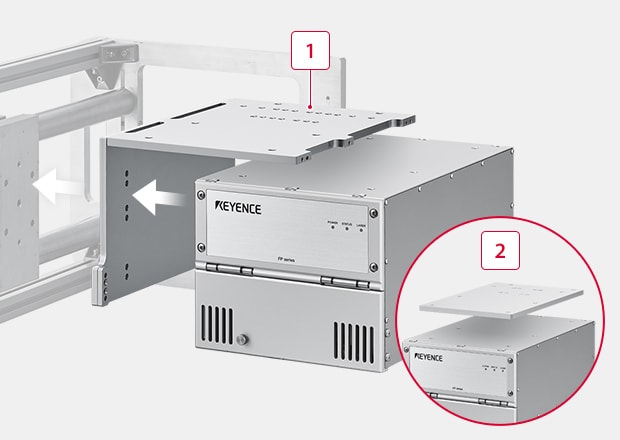

Compatible with Various Packaging Machines

The compact head design allows for seamless installation, effortlessly replacing existing thermal printers. Works with horizontal and vertical pillow-type, bag-feeding, and stick packaging machines.

-

1L-shaped mounting bracket OP-88709

-

2Ceiling mounting bracket also available

Simple Operation

The user-friendly touch interface caters to operators of all skill levels and enables easy programming with minimal training, reducing the risk of errors.

No periodic parts replacement required

No periodic maintenance/inspection required

Reduce Downtime

Eliminate the need for ink ribbon replacements and head cleaning associated with traditional thermal printers. This enhances Overall Equipment Effectiveness (OEE) and increases production throughput.

-

1More production in the same amount of operation time

-

2Less operation time for the same production volume

Curious about our pricing?

Click here to find out more.

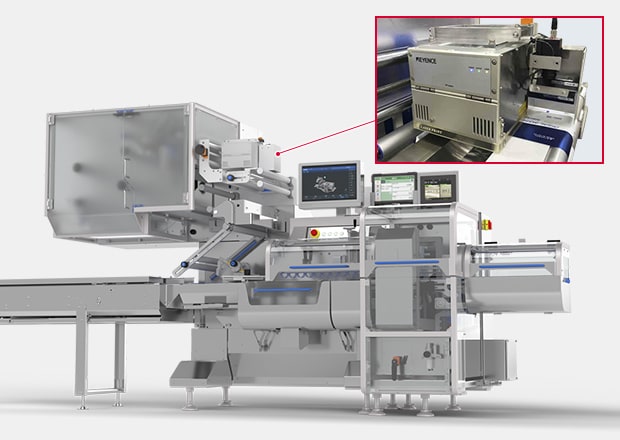

Installation of UV Laser Coders on Various Packaging Machines for Consumer Products and Pharmaceuticals Manufacturing

Horizontal Form Fill Seal (HFFS)

UV laser coder heads are easily installed on Horizontal Form Fill Seal (HFFS) pillow packaging machines. Mount the coder, ensure proper alignment with the film, and adjust the software settings.

Vertical Form Fill Seal (VFFS)

Effortlessly improve tracking and traceability of bags and pouches on vertical film packaging lines by integrating UV laser coder heads into your current equipment.

Rotary Bagger

To install UV laser coder heads on rotary baggers, attach the coder, ensure proper alignment with the bags, configure the software, and verify the markings.

Stick Packaging

Effectively mark long, narrow pouches by incorporating UV laser coders into stick packaging machines. Once the coder is in place, adjust the settings and begin operations.

Pouch/Bag Filling

Securely attach the UV laser coder heads to pouch and bag filling machines, aligning them precisely with the pouch openings to enhance overall throughput.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Marking and Coding for the Consumer Products and Pharmaceuticals Industry

What Are the Advantages of Using UV Laser Coders for Lot and Expiration Date Markings in the Pharmaceutical Packaging Industry?

Using UV laser coders in consumer products and pharmaceutical packaging provides permanent, high-contrast markings, ensures compliance with regulations, reduces costs by eliminating consumables, and improves traceability.

Are UV Laser Coders Suitable for High-Volume Production Lines in the Consumer Products and Pharmaceutical Industries?

Yes, UV laser coders are ideal for high-volume production lines due to the high-absorption rate of UV laser wavelength. Fast marking speeds, reliability, and minimal maintenance speed up operations.

How Does UV Laser Coding Technology Support Anti-Counterfeiting Measures in the Pharmaceutical Industry?

UV laser coding strengthens the industry's anti-counterfeiting efforts by creating permanent codes linked to verification databases, ensuring authenticity and traceability throughout the supply chain.

How Does UV Laser Marking Enhance Traceability and Compliance in Consumer Products and Pharmaceutical Manufacturing?

UV laser marking provides clear, permanent codes with batch numbers and expiration dates for tracking and adherence to regulatory standards. Codes are also immune to post-marking damage.

What Are the Key Factors to Evaluate When Selecting a UV Laser Coder for Both Consumer Products and Pharmaceutical Packaging?

Coding speed, throughput, total cost of ownership, environmental impact, compatibility with materials, marking durability, ease of integration with existing packaging machines, maintenance requirements, and overall cost efficiency should be considered.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)