Coding on Cosmetics, Personal, and Home Care Packaging with UV Laser Technology

The FP-1000 Series UV laser coder’s advanced technology makes coding in cosmetics, personal, and home care industry applications simple. It serves as a seamless replacement for traditional thermal transfer overprinters (TTO), delivering precise, durable codes without requiring any alterations to existing packaging materials or machinery.

UV Laser Coding and Marking in Cosmetics, Personal, and Home Care Packaging Industry

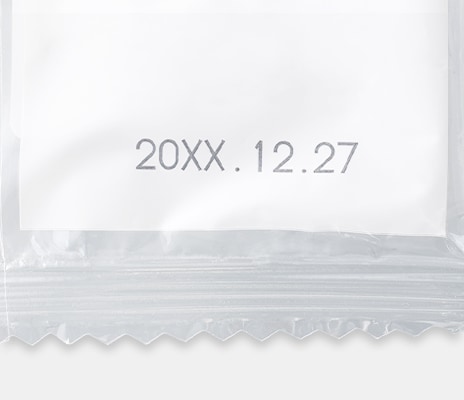

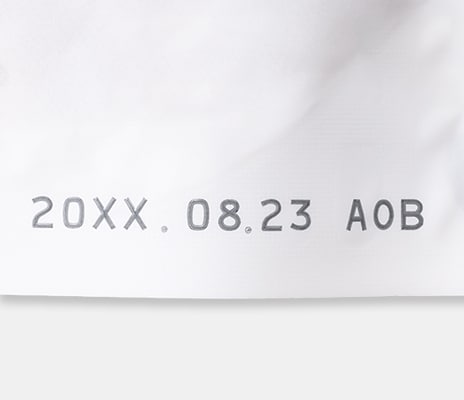

Simplifying UV laser coding and marking in cosmetics, personal, and home care industry products, the FP-1000 Series marks on flexible films, foils, paper-based, plastic, and other packaging materials found in your local drug store, including:

- Single-use lotions and creams

- Wipes

- Pill sachets

- Toothpaste

- Cough drops

- Over-the-counter medications

- Cleaning products

- Eye masks

- Hairspray and dry shampoo samples

- Lip gloss samples

- Band-aids

- Pain relievers in single-dose packets

- Vitamin and supplement packets

- Herbal tea bags

- And more

Candy package

Toothpaste tube

Seasoning package

Retort food pouch

We’re here to provide you with more details.

Reach out today!

Cosmetic, Personal, and Home Care Packing Challenges Solved by KEYENCE UV Laser Coder Technology

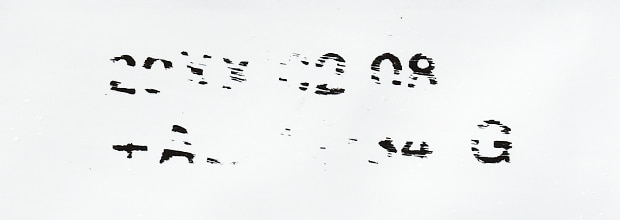

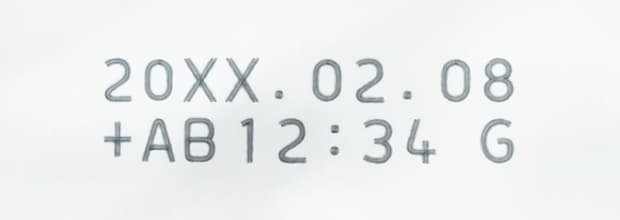

Fading Ink on Packaging Materials

Ink fading or unreadable marks on films and other packaging materials can be eliminated. The FP-1000 Series produces long-lasting, highly visible markings that remain intact.

UV lasers are not affected by traditional causes of marking that fades away:

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

Conventional ink-based systems

UV laser coder

-

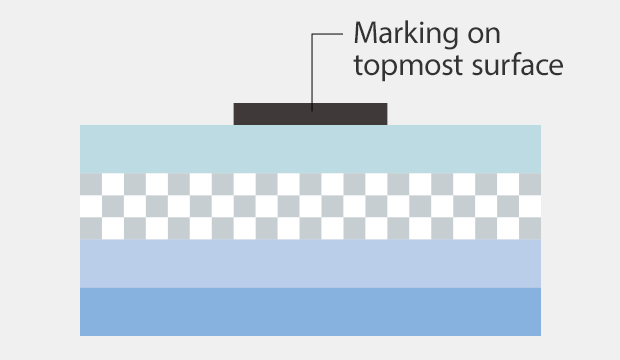

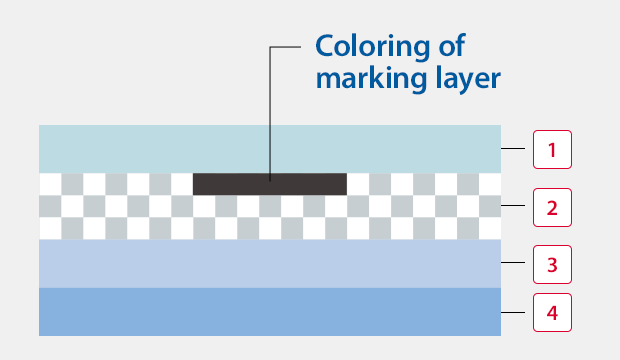

1Laminated surface (transparent)

-

2Marking layer

-

3Other film layers

-

4Sealant layer

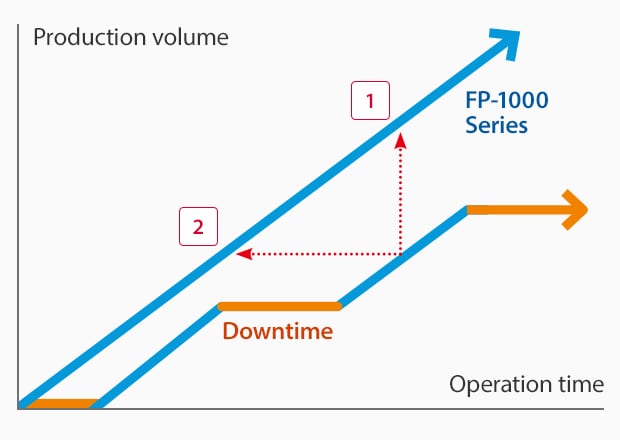

Costly Production Downtime

Frequent interruptions for ribbon or thermal head replacement can halt production, resulting in costly delays. The FP-1000 Series' non-contact, consumable-free design minimizes these stoppages, ensuring continuous production.

-

1More production in the same amount of operation time

-

2Less operation time for the same production volume

No downtime for cleaning

No downtime for replacement

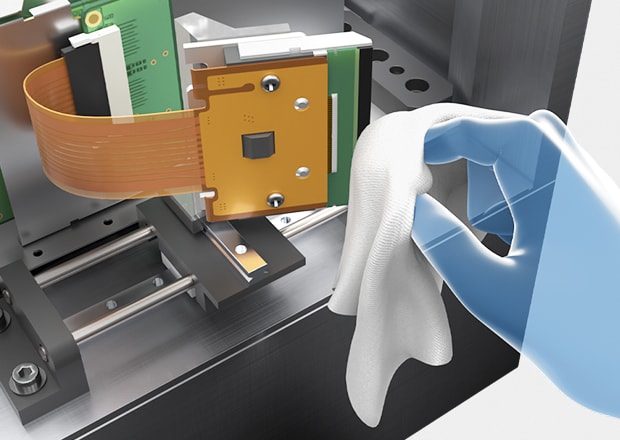

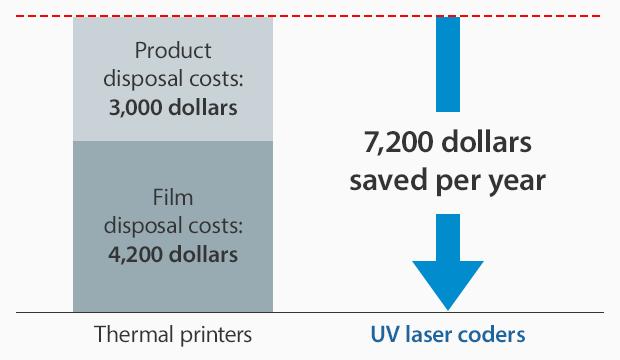

Costly Consumables

TTO printing in the cosmetics, personal, and home care industries can be costly. The FP-1000 Series eliminates consumables and periodic part replacements, cutting overall costs.

Cost reduction example:

With film costs of 0.04 dollars/sheet, 350 sheets of film wasted/day at a product unit price of 1 dollar/item and with product waste of 10 items/day, operating for 25 days a month.

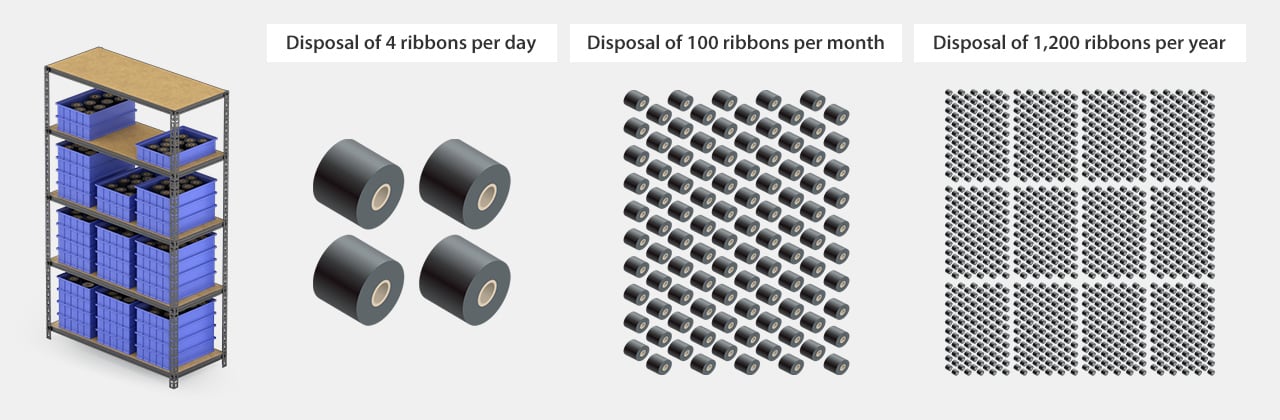

Environmental Waste

Many coding methods generate waste from consumables like ribbons or inks. With the FP-1000 Series' consumable-free technology, businesses can significantly reduce their environmental impact.

Disposal loss simulation:

For a facility that replaces four ink ribbons per day, operating at 25 days per month will lead to disposal of 1,200 ink ribbons per year. At 500 grams 17.65 oz per ink ribbon, 1,200 ink ribbons would equal 600 kilograms 1322.76 lb, or about 1.2 tons of CO2 emissions upon disposal. UV laser coders, however, do not use ink ribbons, so the CO2 emissions can be reduced to zero.

Why Choose the FP-1000 Series for Cosmetics, Personal, and Home Care Product Marking Needs?

Precise, high-speed, non-contact UV laser marking eliminates downtime and consumable costs. High-contrast, permanent marks ensure reliable tracking and traceability across films and various packaging materials, withstanding transport, storage, and handling. Seamlessly integrate the FP-1000 Series into your production line for flawless, durable marking. Contact us today for a product demo of the FP-1000 Series to see how to streamline your operations, reduce costs, and enhance product branding.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Technology in Cosmetics, Personal and Home Care Industry

What Makes UV Laser Marking Superior to Traditional Ink-Based Systems Like TTO for Cosmetics and Home Care Products?

UV laser marking is superior because it offers permanent, high-resolution codes without consumables like ribbons or inks. Smudging and fading risks can be eliminated.

How Does UV Laser Coding Help Reduce Costs in the Cosmetics and Personal Care Packaging Industry?

Ongoing operational costs are drastically cut by eliminating consumables like ink and ribbons, providing a more cost-efficient solution for production lines.

What Advantages Does UV Laser Coding Offer for Marking on Dusty or Wet Surfaces in Cosmetics and Personal Care Products?

UV laser coding is non-contact, meaning it works effectively even on dusty or wet surfaces, ensuring clear and durable marks without smudging or loss of quality.

How Does UV Laser Coding Benefit the Cosmetics, Personal, and Home Care Packaging Industry?

Product aesthetics are enhanced with clean, precise marks, and UV lasers support eco-friendly operations by eliminating waste and consumables.

How Does UV Laser Coding Help Eliminate Production Downtime in the Cosmetics and Personal Care Industry?

With no consumable replacements or frequent maintenance, UV laser coding minimizes downtime, boosting production efficiency and a smoother workflow.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)