UV Laser Coding and Marking on Nutraceutical Packaging

The nutraceutical industry—a thriving sector blending “nutrition” and “pharmaceuticals”—offers products aimed at promoting health, preventing chronic diseases, and supporting bodily functions. Essential to contemporary wellness, nutraceuticals range from functional foods enhanced with probiotics and omega-3 to dietary supplements like vitamins and herbal extracts. The demand for these products is rising, along with the challenges of packaging them efficiently, sustainably, and in full compliance with industry standards. UV laser technology enhances coding on nutraceutical packaging by replacing traditional thermal transfer overprinters (TTO). Durable, precise codes are possible while eliminating the need for consumables.

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

The Growing Importance of Specialized Nutraceutical Packaging

Not all packaging solutions are equal, and that is true for nutraceutical products. The best packaging includes:

- Protective Functionality: Shielding products from moisture, oxygen, light, and contaminants to preserve potency and shelf life.

- Consumer-Friendly Design: Incorporating resealable options, single-dose formats, and easy-to-open features for convenience.

- Brand Differentiation: Employing vibrant colors, unique shapes, and premium finishes to stand out on shelves.

These features are exemplified in common nutraceutical packaging types like blister packs, bottles, stick packs, sachets, and resealable pouches, all tailored to meet the diverse needs of the sector.

Granule package

Retort food pouch

Toothpaste tube

Alcohol container

Ink marking

Marking is affected by surface conditions because the ink is transferred onto the film surface.

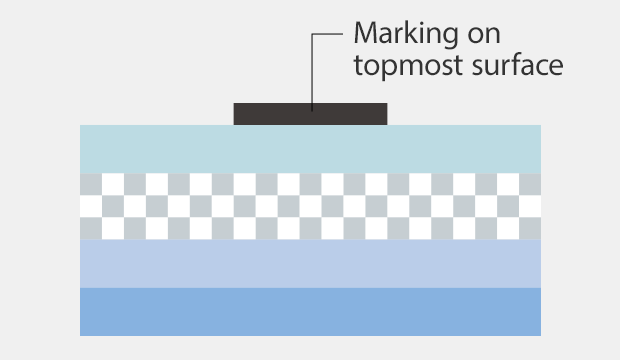

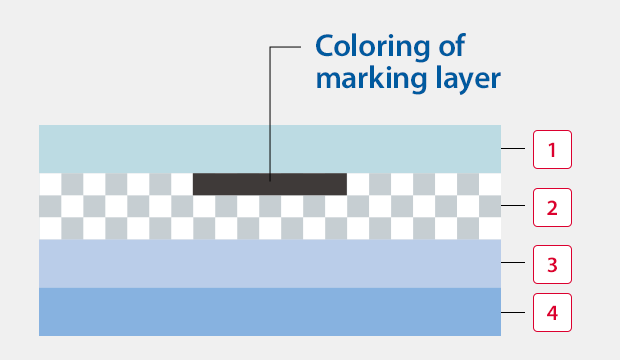

UV laser coder

The marking dose not fade because the color of the marked layer of the film is changed.

-

1Laminated surface (transparent)

-

2Marking layer

-

3Other film layers

-

4Sealant layer

We’re here to provide you with more details.

Reach out today!

Why UV Laser Coding Is a Great Choice for Nutraceutical Packaging

Because UV laser coding creates accurate, long-lasting markings on a range of materials, such as bottles, foils, and multilayer films, it is completely changing the packaging of nutraceuticals. In contrast to more conventional techniques like thermal transfer printing, UV lasers do not require consumables like ink or ribbons, which lowers expenses and waste while simplifying processes. This technology is addressing the key packaging issues in the following ways:

- Durable Markings: Permanent, readable codes withstand handling and storage, ensuring traceability and brand integrity—critical for products like protein powders, capsules, and vitamins.

- Cost Efficiency: By eliminating ink and ribbon costs, UV lasers help manufacturers improve profit margins.

- Operational Uptime: Non-contact marking minimizes downtime, even with high production volumes.

- Sustainability: Waste-free coding aligns with eco-conscious consumer priorities, enhancing brand reputation.

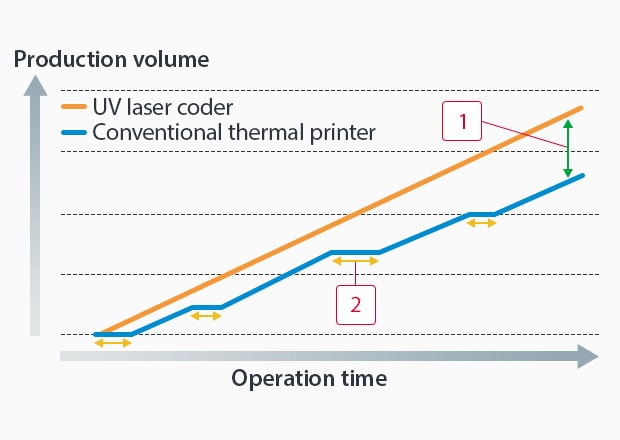

-

1UV laser coders can mark more products in the same operating time

-

2Downtime due to ink ribbon replacement and thermal head cleaning

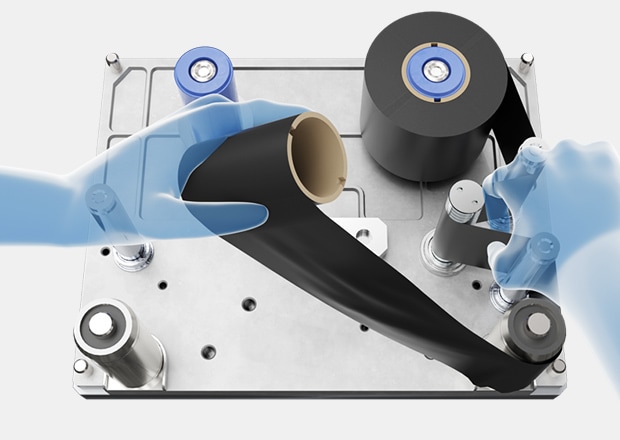

No periodic parts replacement required

No periodic maintenance/inspection required

No ink ribbon costs

No head replacement costs

Curious about our pricing?

Click here to find out more.

Seamlessly Meeting Nutraceutical Industry Standards

Specific standards govern the nutraceutical industry to ensure product safety, quality, and efficacy. These are influenced by governmental organizations, international guidelines, and industry best practices. Key guidelines include FDA’s cGMPs and DSHEA in the U.S., USP standards for purity and potency, and ISO certifications for food safety and quality management.

Whether it’s probiotics, herbal supplements, or nutritional drinks, a reliable UV laser coder solution like the FP-1000 Series ensures:

- Accurate traceability to comply with regulations. The FP-1000 Series utilizes high-precision UV laser technology to create permanent, high-contrast markings on films and packaging.

- Clear, consistent labeling to meet consumer expectations. Conventional ink systems risk incomplete or faded marks, while the FP-1000 Series UV laser ensures permanent, flawless markings even on contaminated surfaces. UV-marked products even resist damage from friction, alcohol, heat, and transportation.

- Operational efficiency and speed for scalable growth. Conventional thermal printers experience downtime due to ribbon replacements and regular maintenance, reducing overall efficiency. In contrast, UV laser coders operate without these bottlenecks, allowing for continuous, high-speed marking and higher throughput on production lines.

Evolving Trends in Nutraceutical Packaging

As with most industries, nutraceutical products and packaging techniques are rapidly advancing to meet new consumer demands. Businesses are placing a higher priority on environmentally friendly operations, and sustainable materials like recycled parts and biodegradable plastics are growing in popularity. Custom branding aimed at niche markets like senior health or sports nutrition is another trend. Tamper-evident seals and anti-counterfeiting features are also increasingly utilized to safeguard product integrity.

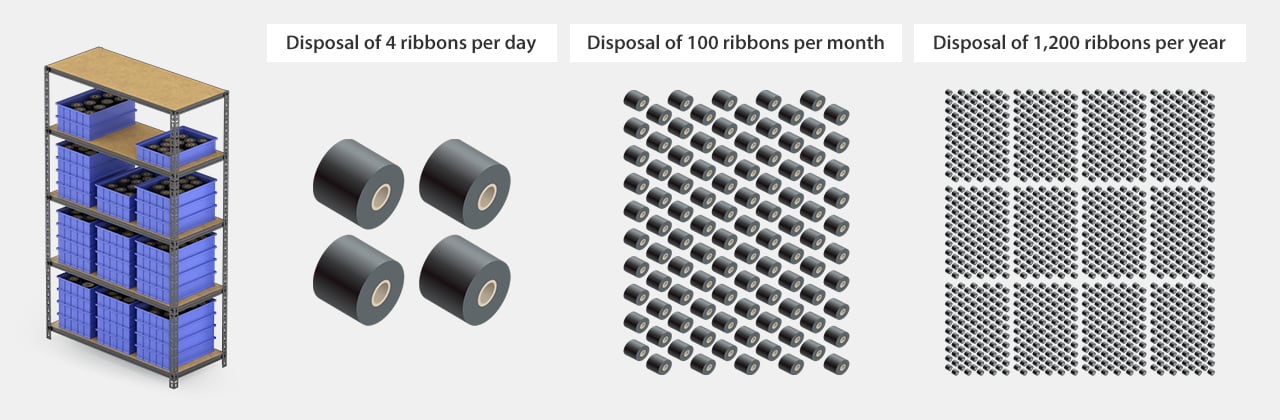

Disposal loss simulation:

For a facility that replaces four ink ribbons per day, operating at 25 days per month will lead to disposal of 1,200 ink ribbons per year. At 500 grams 17.65 oz per ink ribbon, 1,200 ink ribbons would equal 600 kilograms 1322.76 lb, or about 1.2 tons of CO2 emissions upon disposal. UV laser coders, however, do not use ink ribbons, so the CO2 emissions can be reduced to zero.

Elevate Your Packaging Strategy with UV Laser Coding

UV laser coding is an investment in the future of nutraceutical packaging, not just a technical advancement. Every stage of the packaging process is streamlined by UV laser technology, from cost-effective production to environmentally friendly practices.

The FP-1000 Series laser coder assists manufacturers in satisfying consumer demands for sustainability and quality. It features an intuitive touch panel interface, eliminating the need for special training. Pre-registered marking settings can be automatically applied for individual products. The remote monitoring function allows for easy status checks, including marking counts and error statuses, while linking to marking inspection devices is seamless with just one LAN cable.

In a market that is becoming more and more competitive, the right packaging technology can have a major impact. Transform your nutraceutical packaging operations and contact KEYENCE

today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Technology in Nutraceutical Packaging

How UV Laser Coding Reduces Costs for Nutraceutical Packaging

By using UV laser coding, consumables like ink and ribbons are eliminated, reducing nutraceutical manufacturers’ material costs and minimizing maintenance expenses associated with alternative coding methods.

Can UV Laser Coders Be Easily Integrated into Nutraceutical Packaging Production Lines?

Yes, UV laser coders are designed for seamless integration into existing nutraceutical packaging lines without significant modifications, allowing smooth transitions and minimal disruption.

How Does UV Laser Coding Ensure Consistent Marking Quality in the Nutraceutical Packaging Industry?

UV laser coding uses a focused beam of ultraviolet light to etch permanent, high-quality marks, meeting all nutraceutical packaging industry laser marking needs.

What Are the Advantages of FP-1000 Series UV Laser Coders Over TTO Printers in the Nutraceutical Industry?

FP-1000 Series coders offer nutraceutical packers a non-contact solution with permanent markings, no consumable requirements, increased throughput , and reduced downtime compared to TTO printers.

How Does UV Laser Coding Enhance Product Traceability in Nutraceutical Packaging?

UV laser coding in the nutraceutical packaging industry enhances product traceability by creating permanent, high-resolution marks that can be easily scanned and tracked throughout the supply chain.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)