UV Laser Coders for Horizontal Form Fill Seal (HFFS) Packaging Machines

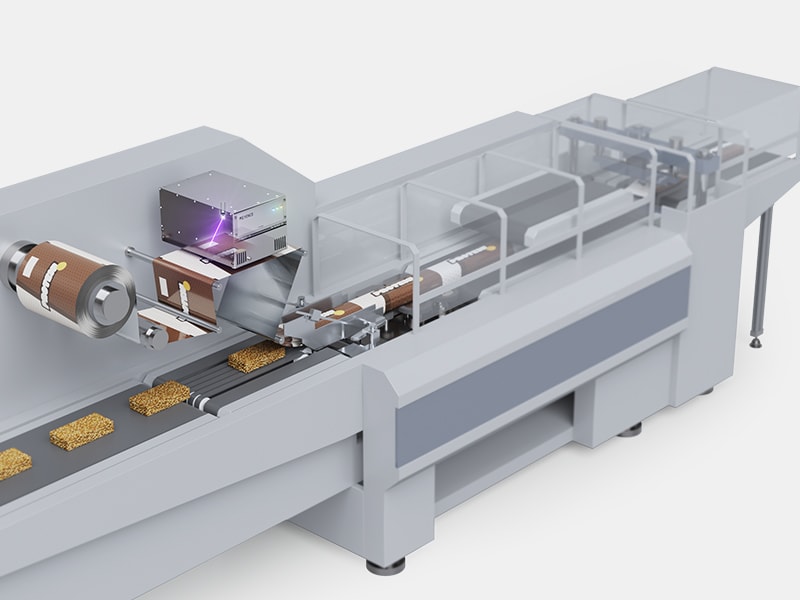

Horizontal Form Fill Seal (HFFS) packaging machines streamline the creation of flexible pouches, packs, flow wrappers, and bags in high-volume production lines. Integrating UV laser coders with HFFS machines provides permanent, high-quality markings while minimizing maintenance needs.

What Is a Horizontal Form Fill Seal (HFFS) Packing Machine?

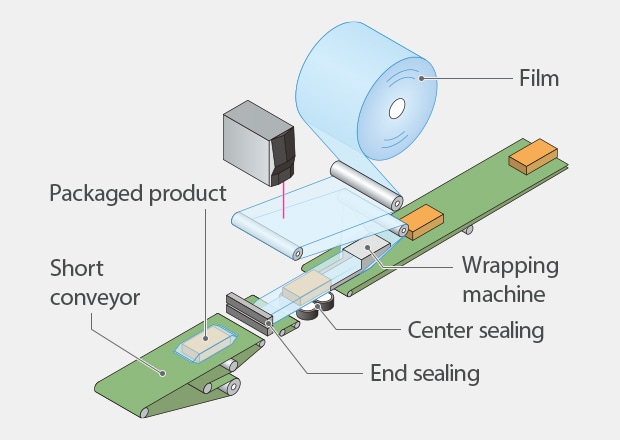

Automated systems known as horizontal form fill seal (HFFS) packaging machines make it easier to create, fill, and seal products with flexible packaging. These machines form packaging material—usually a roll of film—into a pouch, fill it with the desired product, and seal it in one continuous motion. Products that are placed flat or need steady handling during packaging are best suited for the horizontal design.

The HFFS packing process begins with the film unwinding, which is then shaped into a pouch through a Series of rollers and forming tools. The product is dispensed into the formed pouch, followed by sealing the top and edges. In the final step, the completed pouches exit the machine, ready for additional steps such as labeling or coding.

We’re here to provide you with more details.

Reach out today!

Advantages of VFFS Machines

HFFS machines are a common solution in the packaging industry because of their many advantages:

- Versatility: They handle a variety of materials, including laminates and foil, and can accommodate different pouch styles, such as pillow pouches, gusseted bags, or stand-up pouches.

- High Speed: Capable of producing hundreds of packages per minute, they meet the demands of high-volume production lines.

- Precision and Consistency: HFFS systems, which are automated, guarantee accurate filling and sealing, cutting down on product waste and preserving consistency throughout all packages.

- Customization: Advanced models allow for integration with labeling, coding, and additional modules to meet specific packaging requirements.

- Reduced Material Waste: Designed to minimize material waste, these machines contribute to cost savings and environmental benefits.

No periodic parts replacement required

No periodic maintenance/inspection required

No ink ribbon costs

No head replacement costs

Discover more about this product.

Click here to book your demo.

Applications for Horizontal Form Fill Seal (HFFS) Pillow Packaging Machines

Because of their efficiency and versatility, HFFS machines are utilized in a variety of industries. Key applications include:

- Food and Beverages: Ideal for packaging chips, biscuits, sauces, and single-serve beverage sachets.

- Pharmaceuticals: Used for powders, tablets, capsules, and liquid doses in medical packaging.

- Personal Care Products: Perfect for items like sachets of shampoos, lotions, sunscreens, and creams.

- Household Products: Suitable for detergents, wipes, dishwashing powder, and other consumer goods.

Packing sample

Packing type

HFFS machines are helping packagers with these and many other products because of their ability to pack both liquids and solids.

Curious about our pricing?

Click here to find out more.

UV Laser Coder vs. TTO for Horizontal Form Fill Seal (HFFS) Packaging Machines

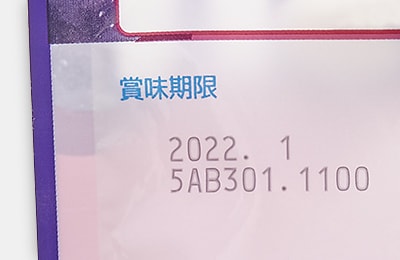

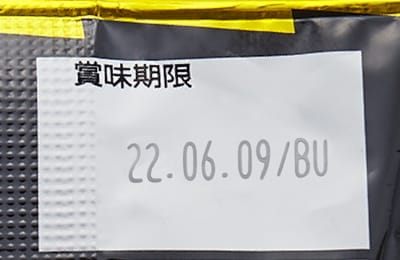

When the completed pouches exit the HFFS machine, they are often labeled or coded to add branding and to ensure product traceability and compliance with industry regulations. Traditionally, thermal transfer overprinting (TTO) has been the preferred method for marking on HFFS packaging.

However, UV laser coders that use concentrated UV light (rather than heat like a TTO) to etch markings onto packaging materials are emerging as a better alternative for numerous reasons.

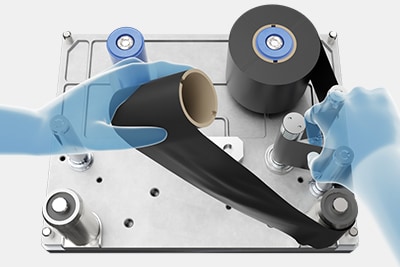

- Consumables: TTO systems rely on ink ribbons, which require frequent replacement, leading to downtime and increased operating costs. UV laser coders eliminate the need for consumables, offering a more cost-effective and sustainable solution.

- Speed and Efficiency: TTO systems may struggle to maintain high-quality markings at the high speeds typical of HFFS lines. High-speed settings are ideal for UV laser coders, which create accurate, long-lasting markings without interfering with production flow.

- Marking Quality: UV lasers create crisp, permanent markings that are resistant to smudging and fading. Even on difficult surfaces like foils and multilayer films, this guarantees constant readability and adherence to stringent industry standards.

- Environmental Impact: UV laser coders generate no waste from ribbons or cartridges, significantly reducing the environmental footprint of packaging operations compared to TTO systems.

- Maintenance and Downtime: Regular ribbon replacements and cleaning are necessary for TTO printers, which can cause downtime and possible production delays. In contrast, UV laser coders are virtually maintenance-free, ensuring uninterrupted operations.

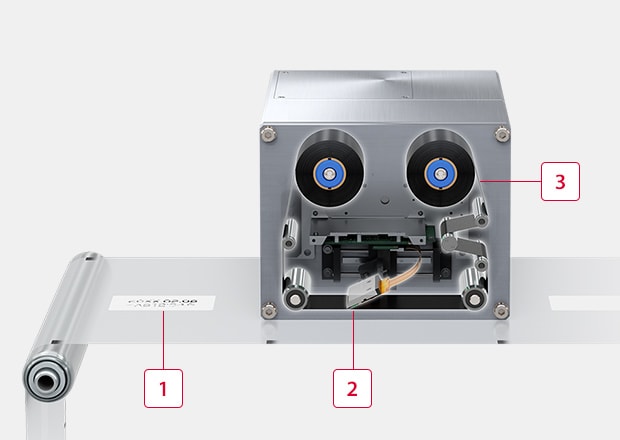

Conventional thermal printer

-

1Risk of marking that fades

-

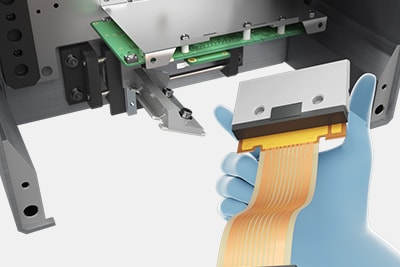

2Thermal head replacement

-

3Ink ribbon replacement required

UV laser coders

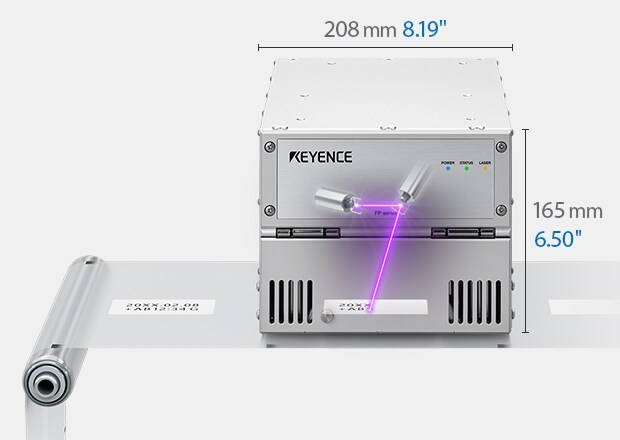

Replacement of current TTO is simple due to similar outer dimentions.

UV laser coder installation on Horizontal Form Fill Seal (HFFS) packaging machines is simple, without requiring modifications to your existing packaging film or production line. For example, the KEYENCE FP-1000 Series laser coder has a compact head that can quickly be installed in place of a thermal transfer printer. Contact us today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Coding for Horizontal Packaging Machines

What Is a Thermal Transfer Overprinter (TTO)?

A TTO is a digital printer that uses heat to transfer ink onto flexible materials. TTOs print barcodes, serial numbers, and expiration dates on food, household goods, and pharmaceutical packaging.

What Is UV Laser Marking Technology?

UV laser marking uses concentrated UV light to etch markings onto packaging materials. As a non-contact method, UV laser coders, like the FP-1000 Series laser coder, create permanent, high-quality barcodes, expiration dates, and logos, ideal for high-speed production lines.

What Types of Packaging Materials Are Compatible With the UV Laser Coder for Horizontal Form Fill Seal (HFFS) Packaging Machines?

The UV laser coder works with various packaging materials, including films for bottles, cartons, frozen bagged vegetables, meat, popsicles, single-serve medications, cough drops, condiments, and cleaning products.

What Maintenance Requirements Are There for UV Laser Coders for Horizontal Flow Wrappers?

The KEYENCE proprietary diode and oscillator design allows for zero maintenance in our UV laser coder, on top of zero consumables and replacement parts of traditional TTO. Integrated seamlessly into HFFS reduces downtime and maintenance costs.

Can the UV Laser Coder Handle High-Speed Production on Horizontal Packaging Machines Like Flow Wrappers, Pillow Packs, or Blister Packs?

The UV laser coder is ideal for high-speed production on horizontal packaging machines like flow wrappers and blister packs, thanks to its fast and precise coding capabilities.

Does the UV Laser Coder Require Special Training to Operate on Horizontal Packaging Machines (HFFS)?

No special training is needed to operate the UV laser coder on HFFS machines, thanks to user-friendly interfaces and software that simplify the learning process for operators.

How Does UV Laser Coding Prevent Product Waste and Film Loss on Horizontal Packaging Lines (HFFS)?

UV laser coding minimizes waste by precisely marking codes on packaging without damage, preventing errors and misprints that could lead to discarding entire batches, saving time and resources.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)