UV Laser Coders for Vertical Form Fill Seal (VFFS) Packaging Machines

Vertical Form Fill Seal (VFFS) packaging machines simplify the production of flexible bags or pouches for a variety of products. Due to their speed and efficiency, VFFS machines are great for high-volume production needs. UV laser coders enhance their performance by delivering high-quality marks with minimal maintenance.

What Is a Vertical Form Fill Seal (VFFS) Packing Machine?

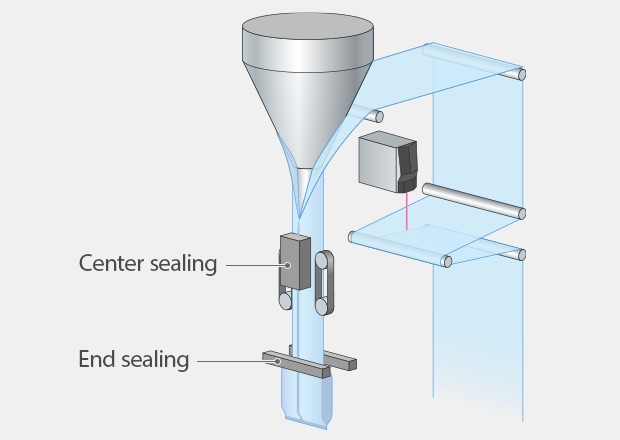

A Vertical Form Fill Seal (VFFS) machine is an automated packaging system that is utilized in consumer goods, food, and pharmaceutical industries. The VFFS machine operates by completing the following steps:

- Form: First, a roll of film is pulled and shaped into a vertical tube using rollers that serve as the packaging's base for the pouch or bag.

- Fill: After shaping the tube, the machine uses an automated filling mechanism to fill it with solids, liquids, granules, or powders.

- Seal: Heat and pressure are used to seal the package after it has been filled, making it airtight or moisture-resistant and preserving the product’s integrity.

- Cut: The sealed pouches are finally cut apart to create individual packages prepared for distribution.

Material

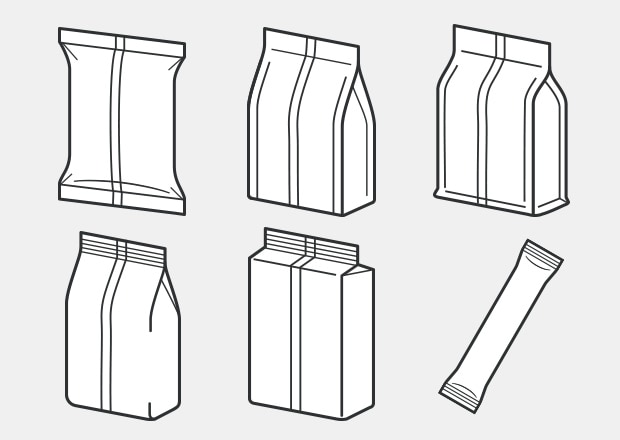

Packing type

These devices are ideal for tasks requiring speed and accuracy because they can produce large quantities of goods with little manual labor.

We’re here to provide you with more details.

Reach out today!

Advantages of VFFS Machines

No periodic parts replacement required

No periodic maintenance/inspection required

Efficient and Cost-Effective

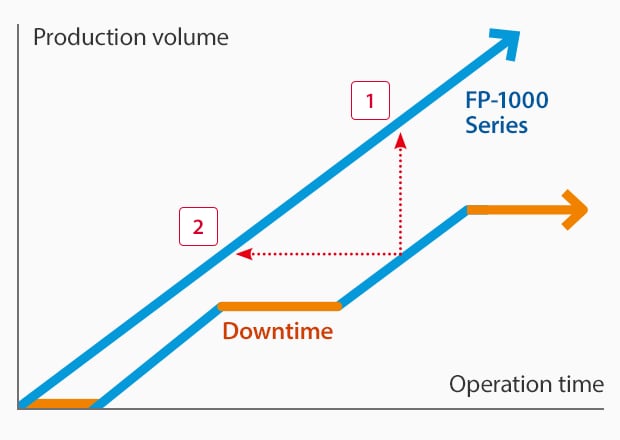

VFFS machines automate the forming, filling, sealing, and cutting processes. This streamlined production reduces manual labor costs, minimizes waste, and speeds up operations. Operational efficiency can be further improved with the addition of a UV laser coder to eliminate downtime and ribbon costs.

-

1More production in the same amount of operation time

-

2Less operation time for the same production volume

No ink ribbon costs

No head replacement costs

Versatile and Customizable

By supporting various packaging sizes, shapes, and materials, VFFS machines are adaptable for many industrial applications.

Easy to Integrate

Functionality can be enhanced as VFFS machines integrate with additional equipment like printers, labelers, and inspection systems.

Ensures Product Integrity

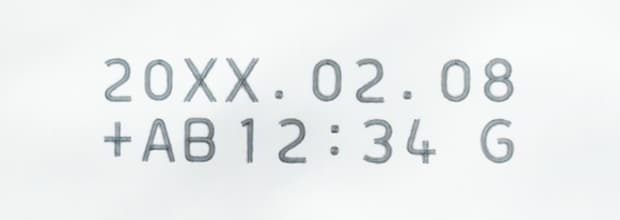

VFFS machines create airtight seals to help maintain freshness and protect products from contamination. UV laser coders guarantee permanent marks for regulatory and traceability requirements.

UV lasers are not affected by traditional causes of marking that fades away:

Oil

Powder

Alcohol

Heat sterilization

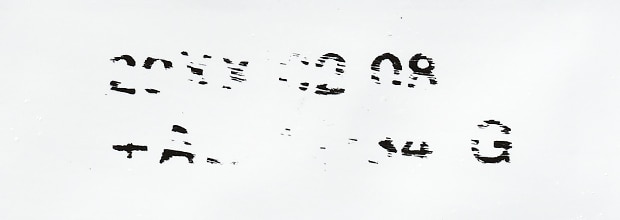

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

Curious about our pricing?

Click here to find out more.

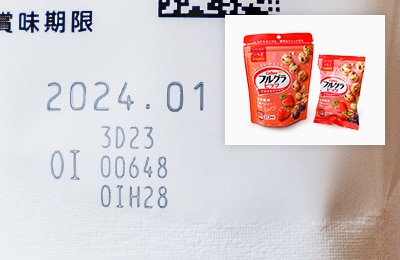

Versatile Applications for Vertical Form Fill Seal (VFFS) Packaging Machines

Vertical Form Fill Seal (VFFS) packaging machines efficiently pack a wide range of products like powders, liquids, granules, and solids across industries such as food, pharmaceuticals, and consumer goods.

- Snack Foods

- Dried Meats & Jerky

- Frozen Foods

- Drink Mixes

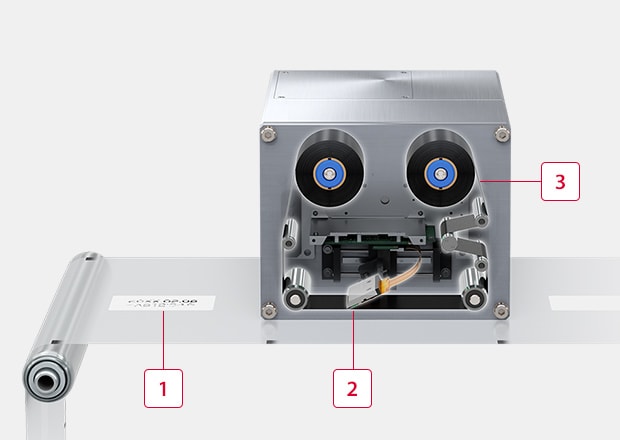

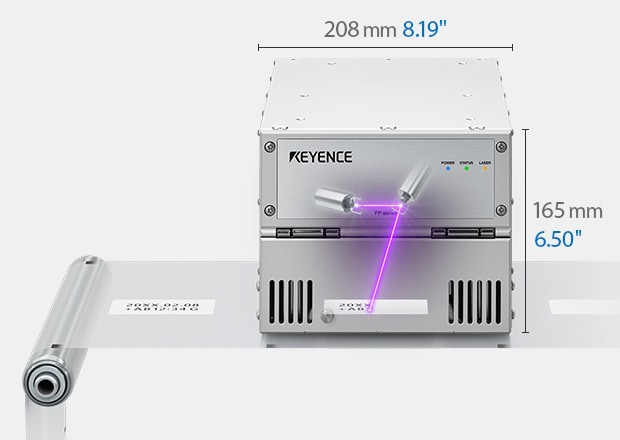

UV Laser Coder vs TTO for Vertical Form Fill Seal (VFFS) Packaging Machines

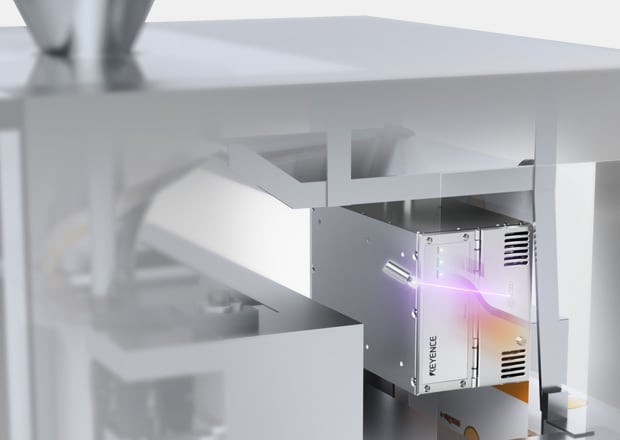

UV laser coders outperform TTO on VFFS machines, offering sharper, permanent markings without consumables, reduced downtime, and superior resistance to contaminants and abrasion.

- Mark Permanence: TTO printers inkjet marks will degrade over time, while UV laser markings are resistant to fading or smudging.

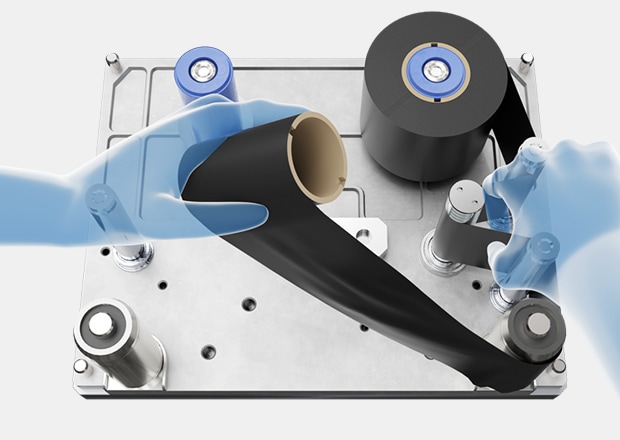

- Increased Uptime: With no ribbons to replace, UV laser systems reduce downtime and keep production lines running smoothly.

- Lower Operational Costs: Since UV laser coding relies on light, there’s no need for consumables or regular part replacements that TTO requires.

- Minimal Maintenance: UV laser coders have fewer moving parts than TTO systems, removing the need for frequent tasks like replacing ink ribbons and cleaning heads.

- Extended Equipment Lifespan: Designed for durability, KEYENCE UV laser coders often last over a decade with consistent performance.

Conventional thermal printer

-

1Risk of marking that fades

-

2Thermal head replacement

-

3Ink ribbon replacement required

UV laser coders

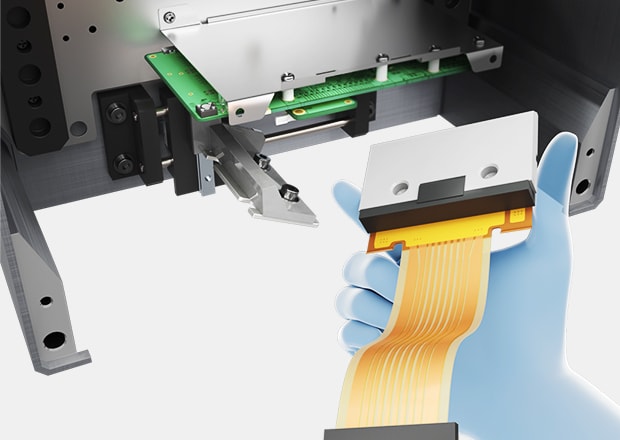

Replacement of current TTO is simple due to similar outer dimentions.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Coding for Vertical Packaging Machines

What Is a Thermal Transfer Overprinter (TTO)?

A Thermal Transfer Overprinter (TTO) is a digital printing technology that uses heat to transfer ink from a ribbon onto a flexible material to create high-resolution codes. TTOs are often used to print barcodes, serial numbers, and best-by dates on packaging for food, household goods, and pharmaceuticals.

What Is UV Laser Marking Technology?

UV laser marking technology marks packaging materials with long-lasting, superior codes, like barcodes, expiration dates, and logos, using ultraviolet (UV) lasers. Perfect for high-speed applications, UV lasers offer permanent marks without the need for contact, consumables, or heat through the use of concentrated UV light pulses.

What Types of Packaging Materials Are Compatible with the UV Laser Coder for Vertical Form Fill Seal (VFFS) Packaging Machines?

A Vertical Form Fill Seal (VFFS) pillow packaging machine with a UV laser coder marks materials like flexible films, stand-up pouches, and seal bags.

What Maintenance Requirements Are There for UV Laser Coders on Vertical Pillow Baggers?

UV laser coders require minimal maintenance, primarily focused on keeping the lens clean and periodically checking system performance to ensure optimal marking quality.

Can the UV Laser Coder Handle High-Speed Production on Vertical Form Fill Seal (VFFS) Packaging Machines?

Yes, UV laser coders are a great choice for high-speed production as they deliver quick marking without slowing down the packaging process.

Does the UV Laser Coder Require Special Training to Operate on Vertical Packaging Machines (VFFS)?

No special training is required. The user-friendly interface allows operators of all skill levels to program and operate UV laser coders easily.

How Does UV Laser Coding Prevent Product Waste and Film Loss on Vertical Packaging Lines (VFFS)?

By eliminating ink-related issues, reducing misprints, and ensuring precise information, UV laser coding prevents product waste and film loss during production.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)