UV Laser Coders for Rotary Packaging Machines

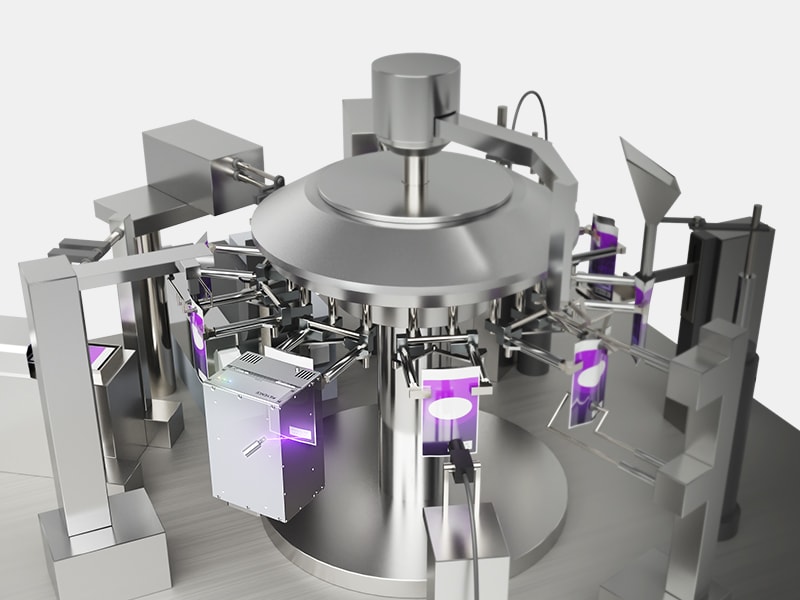

Modern packaging lines rely heavily on rotary packaging machines, which are made to precisely handle high-speed, high-volume production. A rotary bagger is an efficient piece of equipment used by manufacturers and large-scale packaging facilities.

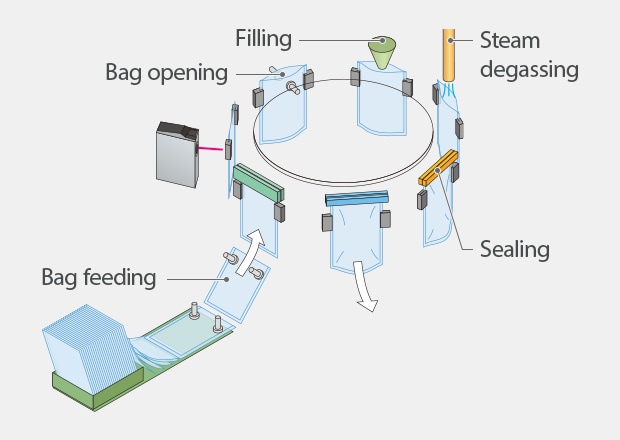

A rotary packaging machine operates by first feeding the product onto the machine and positioning it for packaging. The machine’s rotating carousel then moves the containers or packaging material through various stages of the process. During the filling stage, automatic dispensers or fillers ensure the containers, bags, or pouches are filled with the product. Once filled, the packaging is sealed to keep the product secure and fresh. The packaged product is then released from the machine and prepared for distribution or additional processing.

Common types of rotary packaging machines include:

- Rotary Baggers: These machines fill pre-made bags with products like powders, liquids, or granular materials. A rotary motion allows for quick, continuous filling, making them ideal for high-speed applications.

- Rotary Pouchers: Similar to baggers, these machines are used to fill flexible pouches or sachets with products (typically used for liquids, snacks, or single-serving products).

- Rotary Filler Machines: These machines dispense precise amounts of a product into containers, such as bottles or jars (used in industries like beverages, pharmaceuticals, and chemicals).

Rotary packaging machine

Packing type

We’re here to provide you with more details.

Reach out today!

Limitations and Challenges of Traditional Thermal Transfer Overprinting (TTO)

In the packaging process, TTO has been the go-to technology for coding and marking products. The ink from a ribbon is transferred onto the product or packaging using heat. Despite its potential utility, TTO has its drawbacks, particularly with high-volume production lines where speed is critical:

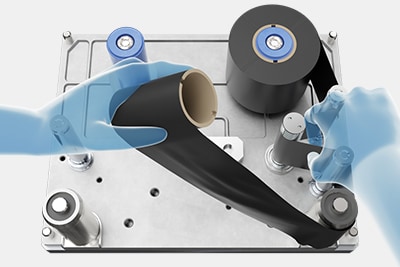

- Ink Ribbon Maintenance: Consumables like ink and ribbons used in TTO systems need to be changed frequently, causing downtime, higher operating expenses, and ongoing inventory control.

- Print Quality Issues: TTO technology can sometimes produce inconsistent print quality, particularly under high-speed conditions. Factors like ribbon slippage, uneven pressure, or even environmental conditions can result in faded, incomplete, or illegible markings.

- Environmental Impact: Waste from consumable use in TTO systems presents challenges for sustainability initiatives in sectors aiming to lower their carbon footprint.

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

Discover more about this product.

Click here to book your demo.

How the FP-1000 Series Laser Coder Solves These Issues

The FP-1000 Series laser coder offers a groundbreaking solution to the limitations of TTO systems. Using UV laser technology instead of consumable ink ribbons addresses key challenges in rotary bagger operations.

- No Consumables: One of the most significant advantages of the FP-1000 Series is its ability to mark products without the need for ink ribbons or other consumables. Maintenance costs and downtime for ribbon replacement are eliminated.

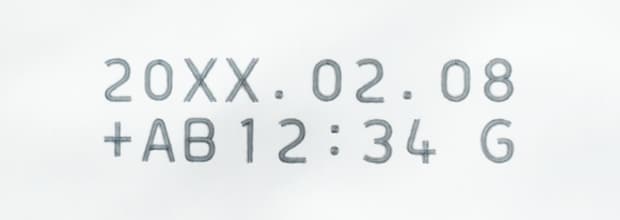

- Superior Marking Quality: UV laser coders produce permanent, high-quality marks on packaging materials, even in high-speed environments. Sharp, readable codes that are impervious to fading, smudging, or deterioration over time are produced by the laser. Marking can also be done on gusset areas and film edges, even where thickness varies or equipment interference occurs.

- Sustainability: The FP-1000 Series significantly reduces environmental impact by eliminating waste from ink ribbons and reducing energy consumption compared to traditional thermal printers. Industries are increasingly moving toward more sustainable practices, and the FP-1000 Series provides an eco-friendly solution for packaging operations.

- Flexibility Across Materials: Ideal for marking a wide variety of packaging materials, including films, foils, and multilayer structures, the FP-1000 Series is an excellent choice for products like food, beverages, and nutraceuticals.

-

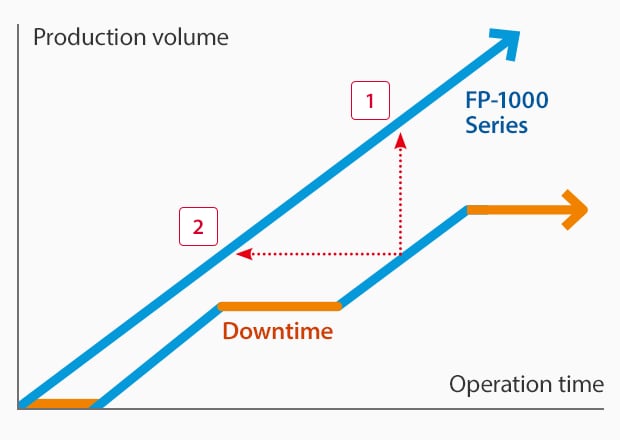

1UV laser coders can mark more products in the same operating time

-

2Downtime due to ink ribbon replacement and thermal head cleaning

No periodic parts replacement required

No periodic maintenance/inspection required

No ink ribbon costs

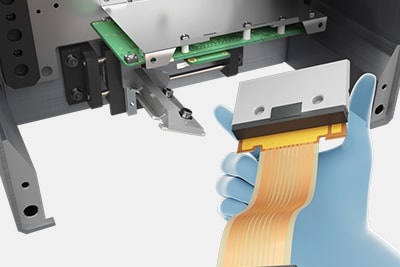

No head replacement costs

Ready for a quicker, more effective, and environmentally friendly coding solution? Contact us today to speak with a specialist or to receive a product demo.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Coding for Rotary Pouch and Bag Filling Machines

Can the UV Laser Coder Handle High-Speed Production on Rotary Pouch Packaging Machines?

Yes, UV laser coders can handle high-speed production on rotary pouch packaging machines. A UV laser coder for pouch filler operates at a line speed of 150 meters per minute, handling up to 1,000 items per minute.

How Does UV Laser Coding Prevent Product Waste and Film Loss on Rotary Packaging Machines?

UV laser coding prevents product waste and film loss by providing precise, non-contact markings, reducing the need for consumables and minimizing errors.

Are UV Laser Coders Suitable for Marking Various Pouch Sizes on Rotary Bagging Machines?

Yes, UV laser coders are suitable for marking various pouch sizes on rotary bagging machines, with adjustable settings to accommodate different formats.

Can UV Laser Coders Integrate Seamlessly with Existing Rotary Packaging Machine Setups?

A UV laser coder for rotary baggers and fillers can integrate seamlessly with existing packaging machine setups, enhancing production without requiring significant modifications. The compact marking head easily replaces thermal transfer overprinters, and an optional bracket simplifies installation further.

What Are the Installation Requirements for UV Laser Coders on Rotary Bagging Machines?

To install UV laser coder heads on rotary baggers, securely attach the coder, align it with the bags, configure the software settings, and test for accurate markings.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)