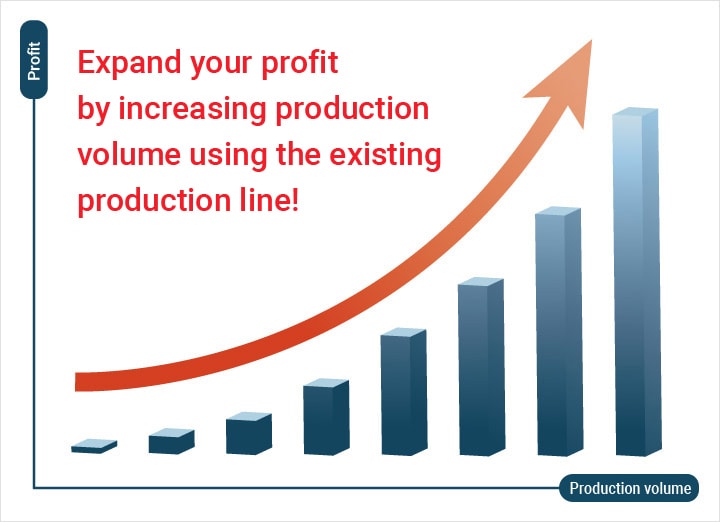

Improved Profitability Through Increased Production Takt/Equipment Takt

Improving production efficiency and increasing profits through the introduction of an image processing system

Machine vision and image processing technologies are absolutely necessary for factory automation (FA). This page considers the advantages of introduction in terms of profitability improvements. Knowing about these promising effects allows introduction of a more suitable system with minimum risk from equipment investment. The first topic describes the advantages of image processing systems from the aspect of improving profitability by increasing production takt/equipment takt.

How to increase profit by introducing image processing?

You can consider two general approaches to expand production profit: "Increasing production volume" and "reducing production costs." This section focuses on increasing production volume and explains how to improve profitability.

The key is to increase the throughput (production efficiency)

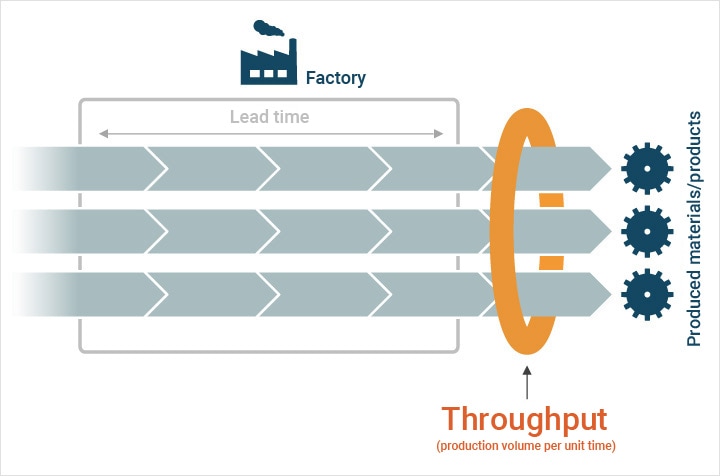

To increase production volume, you need to increase the production efficiency of a line or an entire factory. To that end, the idea of throughput is important. Throughput is the maximum rate at which something can be processed per unit time (processing speed). In manufacturing sites, it can be thought of as production volume per unit time.

In recent years, demands are high for facilities and lines to deliver high throughput (high production volume). The recent trend is production systems that can deliver high throughput with short lead times (time or period from the supply of materials or parts to the completion of products).

Increasing throughput enables maximization of the production capacity of a facility or a line. This is also effective for reduction of equipment investment and labor costs because, for example, two lines producing the same product can be consolidated into a single line. Increasing throughput is thus an effective approach for optimizing business efficiency.

Image processing systems effective for throughput improvement

To improve throughput, you need to increase the operating rate of each process by reducing connection losses. In recent years, many different facilities offering high production efficiency have been appearing, but it is impossible to increase production volume unless these facilities can deliver their full performance. For example, even when you introduce the most sophisticated production line, there is no point if you have to limit the production speed to the speed of visual inspection. Identifying bottlenecks in production lines and resolving them will improve throughput.

How to prevent an inspection process from becoming a bottleneck?

On manufacturing sites, the importance of product quality and safety is increasing year after year, and the tendency for inspection processes to become bottlenecks is growing. Many items are still inspected visually and there may be no choice but to conduct complicated inspections offline. Delegating such visual confirmation/differentiation to an image processing system can eliminate the bottleneck. High-accuracy, high-speed inspection has become indispensable for the improvement of throughput, and image processing systems are drawing attention as one of the solutions.

Have you ever experienced problems like these?

If you have experienced any of the following, you can expect to see profitability improvements by taking remedial action.

- The production speed of the facility/line needs to be decreased to maintain quality.

- The production system is designed in accordance with the speed of image processing or inspection.

- It is necessary to have several production lines and factories in order to increase productivity.

- The production line is divided into two at the inspection points in order to keep up with productivity.

- Various inspections are allocated to more than one inspection device in order to maintain productivity.

Recent improvements in the processing speed of machine vision and the advances in image processing technologies have enabled automatic inspection at ultra high speed. The XG-X Series machine vision has made significant improvement in image processing performance compared with conventional models by having 14 cores, the largest number in the industry. This allows a single system to conduct inspections that have been done visually or with several types of inspection equipment. It is also possible to conduct conventional offline inspection online, which eliminates the need of stopping production and increases the net operating time of the production line.

Using image processing technologies improves efficiency, resulting in higher throughput and a powerful profitability improvement effect.

Example of throughput improvement

This section introduces a calculation formula for simple estimation of improved profitability through improved throughput. Please try it to get an estimation of the effect on your production. You can use the profitability improvement calculation sheet below by just typing in the appropriate numbers.

Profitability improvement calculation

( Facility productivity - Current inspection capability ) × Product value × Operation hours = Profit improvement effect

(【①】products/min.)-【②】products/min.) x 60 minutes × $【③】 × 【④】hours × 【⑤】days = enhanced throughput of $ 【 】/month

Profitability improvement calculation sheet

| ① Facility productivity | products/min. | |

|---|---|---|

| ② Current inspection capability | products/min. | |

| ③ Product value | $ | |

| ④ Operation hours(hours) | hours | |

| ⑤ Operation hours(days) | days | |

enhanced throughput of $ 0 /month

Please enter a numeric value

{item} is required.

{item} must be a positive values.

{item} must be an integer.

Calculation example

Assume that your facility/line is capable of producing 150 products/minutes, but the current inspection capacity is 100 products/minutes. The product unit price is $1, the operating time per day is 8 hours, and the number of operating days per month is 20. The effect of profitability improvement can be calculated as follows:

(150 products/minute - 100 products/minute) x 60 minutes x $1 x 8 hours x 20 days = $480,000 /month

Increase in monthly production: 48,000 products

Improved throughput per month: $480,000!

![A Technical History of Image Processing Vol.1 [Camera]](/img/asset/AS_46814_L.jpg)

![The Latest Image Processing Applications [Transportation Industry]](/img/asset/AS_71759_L.jpg)

![The Latest Machine Vision Inspections [Food and Medical Industries]](/img/asset/AS_72814_L.jpg)