Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

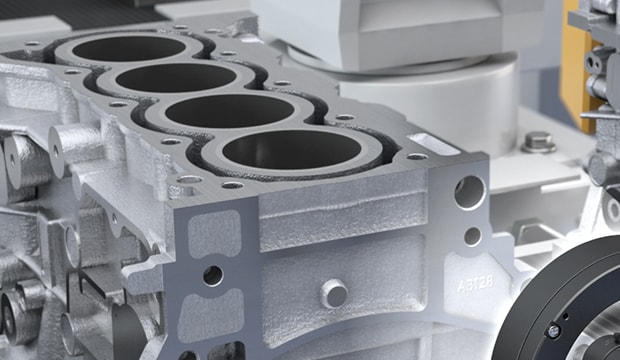

Vision Systems for the Automotive Manufacturing Industry

Explore our automotive industry-focused vision systems designed to streamline surface, dimensional, and assembly line inspections for various auto parts.

Precision in the automotive industry is important, and KEYENCE offers a wide range of machine vision solutions for a variety of measurement and inspection needs, ranging from component manufacturing to body assembly and quality control.

The KEYENCE VS Series provides fast and accurate machine vision solutions. Features like one-click image optimization and powerful AI tools help manufacturers meet regulatory standards and ensure quality control.

Inspection of rubber brushings

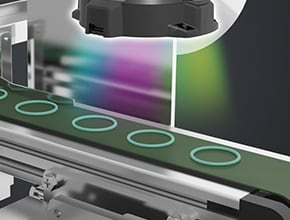

O-ring color difference inspection

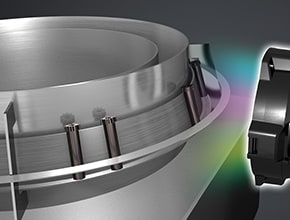

Missing-roller inspection for bearings

Shaft material sorting

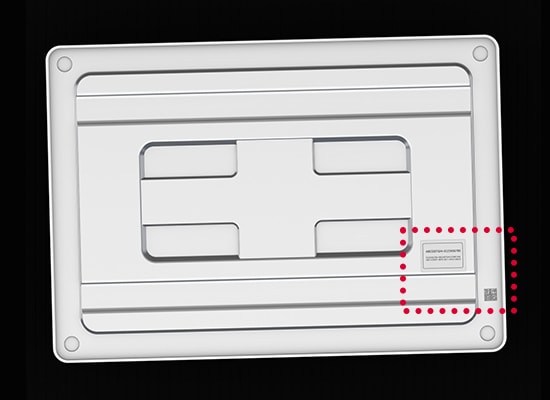

Inspection of engraved characters of an ECU case

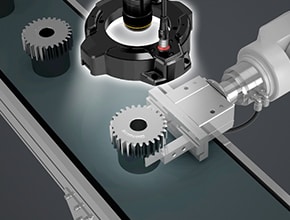

Inspection of engraved characters on a gear

Burn-mark inspection

Sealant coat inspection

Applications of Automotive Vision Systems

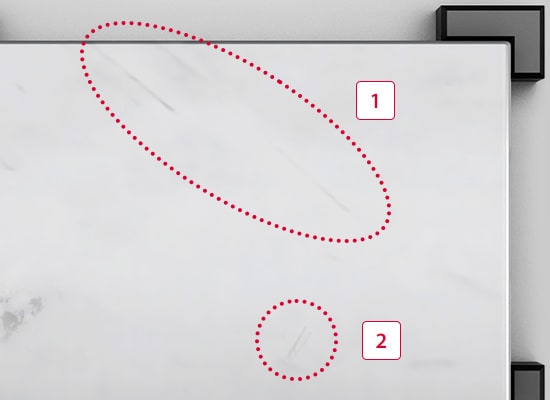

Surface Inspection of Automotive Parts

In the context of quality inspection for the automotive industry, vision systems are typically employed to inspect the surface paint quality on bodywork and detect defects like runs, dirt, or orange peel texture. Early detection of these defects is essential, as it allows for corrective action before further assembly, reducing waste and rework.

Normal image

-

1Scratch

-

2Dent

LumiTrax™ image

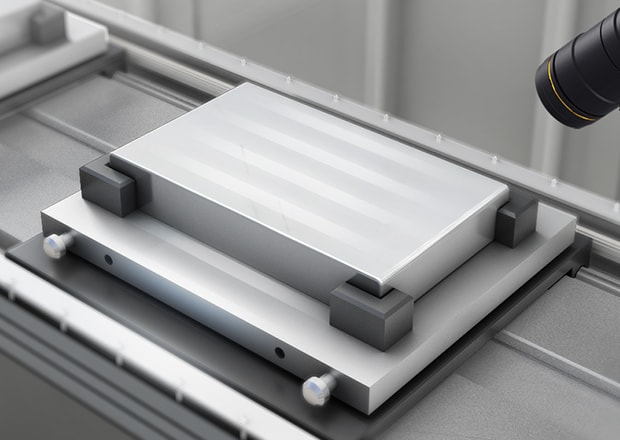

Dimensional Measurement in Automotive Manufacturing

Vision systems for the automotive manufacturing industry are used to measure all the important dimensions and tolerances of the automotive components and body to ensure they meet the specifications. This is crucial for vehicle performance and customer satisfaction.

Whole field-of-view image

Magnified image

Assembly Line Verification

Aside from robot guidance and precise placement in automated assembly lines, a vision system for the automotive manufacturing industry ensures that the assembly is installed correctly, using the correct components. This includes checking for presence, correct orientation, and placement of components used in the assembly.

Introducing Our AI-Powered Vision System for the Automotive Industry

Technological advancements are constantly enhancing workplace efficiency and accuracy, transforming the way businesses operate. AI-powered vision systems significantly improve productivity and minimize errors, leading to consistent, high-quality output. Our vision systems also enable manufacturers to contribute to sustainability by identifying issues early on in the manufacturing process, reducing waste.

The core features of our vision system include:

- Accurate Inspection: Identifies defects and deviations immediately during production.

- Adaptive Learning: Consistently improves accuracy by learning from new data and patterns.

- Scalable Integration: Easily integrates with the existing manufacturing system for seamless automation.

- High-Speed Processing: Analyzes vast amounts of visual data quickly, maximizing production uptime.

Discover how our vision system can transform your manufacturing process and elevate your production efficiency and operation quality today.

Applications and Examples

FAQs About Vision Systems in the Automotive Industry

What Are the Benefits of Using Vision Systems in the Automotive Industry?

The automotive industry is governed by strict regulations and standard requirements for quality, safety, and efficiency. It was one of the first industries to embrace robotics in manufacturing and machine vision systems, by extension, as these significantly aid the vehicle manufacturing process.

What Types of Vision Systems Are Commonly Used in Automotive Manufacturing?

Vision systems for the automotive manufacturing industry use a variety of sensors and cameras to ensure precision, quality, and efficiency throughout the entire manufacturing process.

However, these systems are often application-specific, with one part of the manufacturing process relying on its respective vision system.

What Challenges Do Vision Systems Help Address in the Automotive Industry?

Vision systems for the automotive manufacturing industry address various challenges, from parts sorting, material handling, and logistics to vision-guided pick-and-place and welding robots, assembly verification, and quality control.

How Do Vision Systems Support Traceability and Compliance Requirements in the Automotive Industry?

The automotive industry faces strict regulatory standards and high consumer safety expectations, so traceability and compliance requirements are crucial in manufacturing. Vision systems for the automotive manufacturing industry enable manufacturers to track the movement and use of parts and components throughout the manufacturing process, which is important in case of a recall.

What Are the Primary Considerations When Selecting Vision Systems for the Automotive Industry?

Primary considerations when selecting the right vision systems for the automotive manufacturing industry include understanding the specific application needs before finding the right type of vision system. Once found, consider the system’s integration with your current system, its technical specifications, and cost.

How Do Automotive Inspection Vision Systems Improve Defect Detection?

Inspection vision systems for the automotive manufacturing industry improve defect detection through advanced imaging technologies and analytical algorithms—including machine learning and AI.

What Are the Benefits of Using Vision-Guided Robotics in Automotive Manufacturing?

Automotive vision systems enable robots to perform their operational tasks with high precision, including part pickup and precise placement, welding, spotting, detailed inspections, and complex assembly operations.

How Do Automotive Vision Systems Contribute to Cost Reduction and Efficiency Improvement in Manufacturing Processes?

Vision systems for the automotive manufacturing industry help reduce manufacturing costs in several ways. They can perform operational tasks much faster than humans while less prone to errors. This increases operational efficiency while also aiding in defect detection before further value is added. They also reduce manual labor costs, downtime associated with malfunctions, etc.

Related Downloads

Introducing high-performance pattern projection lighting capable of advanced image inspection in both 2D and 3D simultaneously. Browse detailed examples of systems designed to meet a variety of inspection condition needs not possible with conventional methods, as well as automotive industry applications involving a wide range of products, from metal components to electronic devices.

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace