Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Vision Systems for the Mining and Metals Industry

Safety is a top priority in the mining and metals industry. With harsh working environments and heavy machinery, accidents can occur without proper safety measures. Traditionally, manual inspections have also been time-consuming and prone to error.

KEYENCE's vision systems for the mining and metals industry can be used for remote inspections, reducing the need for workers to enter dangerous areas. With its AI and rule-based tools, the system can also detect potential hazards and alert operators in real time.

The VS Series artificial intelligence vision system for the mining and metal industry offers groundbreaking efficiency for a range of tasks by combining accurate imaging, quick setup, and simple adjustments. The user-friendly software allows for swift configuration of various inspections using both AI and rule-based vision tools.

We’re here to provide you with more details.

Reach out today!

Common Vision Applications for the Mining and Metals Industry

Conveyor Belt Monitoring and Inspection

Conveyor belts wear out over time, leading to safety risks and expensive downtime. Mining and metals industry vision systems offer real-time monitoring to detect abnormalities or defects that could cause belt failure.

Quality Control in Metal Manufacturing

Metal manufacturing is precise and complex, where flaws can lead to costly rework or safety hazards. Vision systems for the mining and metals industry provide an efficient quality control solution, allowing for reliable, high-speed inspections.

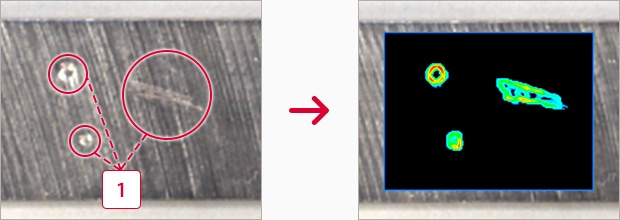

Defect detection for a metal plate

Displays sections having intensity differences in blue to red. In addition, it is clearly identifiable that detected defects differ from the background.

-

1Defect/dent

Discover more about this product.

Click here to book your demo.

Introducing Our AI Vision System for the Mining and Metals Industry

By using leading optical zoom technology to precisely analyze belts, components, and metal surfaces, the VS Series transforms inspection in the mining and metals sector. Its AI-powered precision finds flaws, and rule-based tools guarantee unparalleled quality. Setup is streamlined by intuitive software, which makes it possible to quickly check materials and equipment for consistency and defects.

- Optimal Imaging in One Click: Achieve crystal-clear imaging for metal surfaces and mining equipment effortlessly with AI vision system inspection in the mining and metals industry.

- ZoomTrax for Metals: Seamlessly adjusts to rugged textures without additional tools.

- Dual Inspection Modes: Leverages AI and traditional methods for comprehensive defect and alignment checks.

- Real-Time Insights: Enhances efficiency with instant data visualization and quality assurance.

Unlock next-level precision and adaptability with an AI vision system for the mining and metals industry. Contact us to learn more about the VS Series.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Vision Systems in the Mining and Metal Industry

What Are the Benefits of Using Vision Systems for the Mining and Metal Industry?

Vision systems in the mining and metals industry improve inspection accuracy, enhance safety, and streamline quality control. They detect flaws invisible to the naked eye, ensuring reliable inspections and high-quality standards.

What Types of Vision Systems Are Commonly Used in Mining and Metal Manufacturing?

Mining and metals industry vision inspection systems include 2D cameras, line scan cameras, and 3D cameras, which can be integrated into all-in-one smart cameras or modular high-speed controllers.

What Challenges Do Vision Systems Help Address in the Mining and Metals Industry?

Vision defect inspection systems tackle many challenges like spotting defects in raw materials, ensuring production process consistency and quality, and identifying safety hazards for workers.

How Do Vision Systems Support Traceability and Compliance Requirements in the Mining and Metals Industry?

Vision-guided robotics systems track materials with cameras through processes, recording their journey from extraction to production. This data helps verify regulatory compliance.

What Are the Primary Considerations When Selecting Vision Systems for the Metal Industry?

The size and type of materials, operation speed, and specific defects to be detected should be considered when choosing vision systems for the mining and metals industry.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace