Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Vision Systems for the Electronic Device Industry

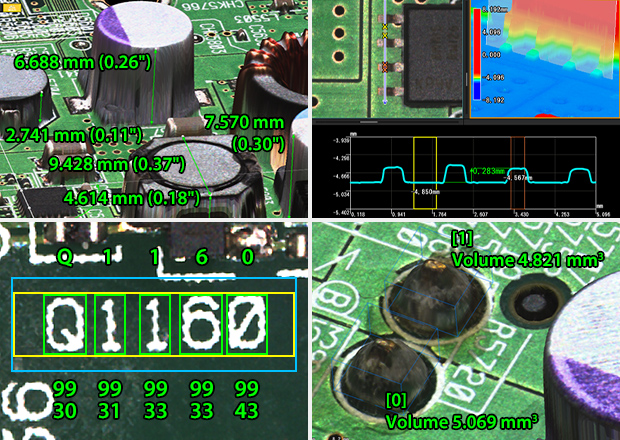

Explore our electronic device industry-focused vision systems designed to streamline defect presence, orientation detection, appearance and dimensional inspections.

As demand for compact, fast, and efficient electronics grows, so does the need for reliable inspection processes.

KEYENCE's vision systems for the electronic device industry offer advanced and customizable features, ensuring quality control and minimizing downtime. These systems integrate easily into tight spaces and high-speed lines, with autofocus and high-resolution imaging for fast, accurate measurements.

The AI-powered VS Series vision system enhances industry processes by delivering precise inspections, fast set-up time, and one-click focus and field of view adjustments, enhancing efficiency across many applications.

Applications of Electronic Manufacturing Vision Systems

Inspection for the Inclusion of Different Harness Types

Harnesses are key in electronics, however, issues like incorrect wiring can cause malfunctions. KEYENCE electronic vision systems inspect harnesses accurately, detecting defects and confirming the inclusion of various harness types.

Lead Frame Coating Inspection

Lead frames need a precise coating for optimal functionality. KEYENCE vision systems in electronic manufacturing detect uneven coatings and scratches, enabling efficient correction and preventing production errors.

Inspection for Missing Solder on PCB

Quality PCBs are vital for device performance and reliability. KEYENCE electronics vision inspection systems equipped with advanced imaging technologies detect voids, bridging, and incomplete or missing solder in solder joints.

Inspecting Wire Bonding

Wire bonding is essential in electronics manufacturing, connecting components with thin wires. KEYENCE vision systems detect defects like broken wires, excess adhesive, and misalignment for optimal device functionality.

Welding Position Defect Inspection for Battery Tab Terminals

In battery production, correct welding positions helps reliability. KEYENCE visual inspection systems detect welding defects fast, ensuring proper welds on battery tabs to reduce malfunction risks.

We’re here to provide you with more details.

Reach out today!

Introducing Our AI Vision System for the Electronic Device Industry

With its industry-first optical zoom for complex components, pinpoint imaging, and AI tools, the VS Series transforms the inspection of electronic devices. Intuitive software supports rapid setup for both AI and rule-based tools, streamlining defect detection and quality control. Designed for speed and accuracy, the VS Series ensures reliable performance, helping to meet the high standards of electronic device manufacturing.

- Precision Imaging for Electronics: Achieve superior image quality in a single step. This is ideal for AI vision inspections in the electronic device industry.

- ZoomTrax for Dynamic Flexibility: Revolutionary optical zoom adapts to diverse electronic components without manual adjustments or extra hardware.

- Dual AI and Rule-Based Tools: Analyze defects, alignments, or markings on electronics using advanced AI or traditional rule-based inspections.

- Streamlined Setup for Complex Systems: Configure inspections for intricate electronic assemblies quickly with intuitive software and task-oriented programming.

Contact us today to discover how the VS Series, our AI vision systems for the electronic device industry, can optimize your electronic device inspections.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Applications and Examples

FAQs about Vision Systems in the Electronic Device Industry

How Do AI-Enabled Vision Systems Benefit Electronics Manufacturing?

AI-powered vision systems enhance electronics manufacturing by better detecting subtle defects like cold solder joints and improve over time as they learn from processed data.

What Challenges Do Vision Systems Face in the Electronics Industry?

With smaller electronics and denser circuits, the need for precise defect detection, high-resolution imaging, and advanced image processing becomes crucial, especially given the diverse materials in components.

What Are the Key Features to Consider When Selecting a Vision System for Electronics Production Lines?

There are several details to consider when selecting a vision system for your production lines, including resolution and image quality, sampling speed, software capability, and its integration with other systems.

How Do KEYENCE’s Vision Systems Improve Quality, Throughput, and Cost-Effectiveness in Electronics Manufacturing?

KEYENCE vision systems are designed to enhance the quality, throughput, and cost-effectiveness of electronics manufacturing through high-resolution imaging and real-time image processing, ensuring timely defect detection.

What Are the Primary Considerations When Selecting Vision Systems for the Electronic Device Industry?

When selecting vision systems for the electronic device industry, the level of accuracy and precision required, speed of production, and compatibility with existing equipment are important considerations.

How Do Vision Systems for Electronics Improve Defect Detection?

Electronic vision systems use high-speed imaging, advanced image processing, and machine learning to improve defect detection, identifying issues like misalignments, faulty solder joints, and invisible electrical failures.

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace