Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Vision Systems for the Printing Industry

Printing companies constantly seek advanced solutions to improve production processes and ensure top-notch results. KEYENCE has been at the forefront of developing innovative vision systems for the printing industry. These systems allow for precise and accurate image detection and are ideal for complex inspection tasks in the printing process.

With its accurate inspections, simple setup, and flexible imaging, the VS Series AI-powered vision system transforms industry processes and improves accuracy and efficiency for a range of printing applications.

We’re here to provide you with more details.

Reach out today!

Applications for Printing Vision Systems

Print Quality Inspection

KEYENCE printing vision systems employ advanced imaging to inspect printed materials for defects, enabling manufacturers to ensure high-quality final products by detecting and correcting errors in the printing process.

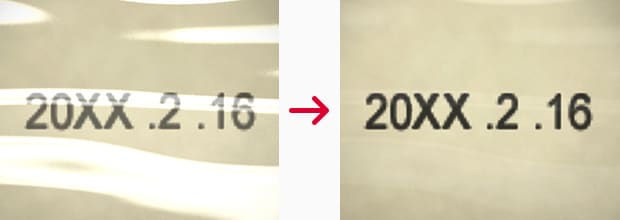

Printed character inspection on a film surface

Tape presence inspection

Color Matching and Verification in Printing

Traditionally, color matching involved manual work with color swatches, which was slow and error-prone. Printing vision systems analyze colors in real-time, highlighting even minor discrepancies and allowing instant adjustments.

Barcode Reading and Verification for Packaging

By using high-speed cameras and advanced software, print inspection vision systems can quickly and accurately read barcodes on packaging, making them an invaluable tool for manufacturers.

Discover more about this product.

Click here to book your demo.

Introducing Our AI Vision System for the Printing Industry

Achieve unparalleled precision and efficiency with our AI vision systems for the printing industry. Designed for printing experts, it improves precision, reduces mistakes, and expedites inspection procedures, guaranteeing consistent output on each production run.

- Advanced AI Processing: Delivers precise inspections, even on intricate printing substrates, colors, or products.

- Effortless Setup: Intuitive interface enables rapid integration into any production line.

- Dynamic Adaptability: Optimized for diverse printing materials and lighting conditions.

- High-Speed Accuracy: Maintains inspection precision without disrupting workflow.

Take the next step toward operational excellence in printing production. Contact us to discover how our artificial intelligence vision system for the printing industry delivers the fastest setup time for users.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Vision Systems in the Printing Industry

What Are the Benefits of Using Vision Systems in the Printing Industry?

With high-speed cameras and advanced software, printing vision systems can quickly identify any issues with printed materials, reducing waste and improving overall product quality.

What Types of Vision Systems Are Commonly Used in the Printing Industry?

With their row of single pixels, line scan cameras are key in the printing industry for high-speed inspection of labels, packaging, and documents, perfect for continuous printing processes.

What Challenges Do Vision Systems Help Address in the Printing Industry?

Vision systems in the printing industry enhance quality control, ensure accurate print placement, and identify defects and errors while verifying print counts and detecting missing pages.

How Do Vision Systems Support Traceability and Compliance Requirements in the Printing Industry?

With advanced technology, vision systems can verify the accuracy of printed labels and codes, track products throughout the production process, and detect any errors or defects that may occur.

What Are the Primary Considerations When Selecting Vision Systems for the Printing Industry?

Vision systems for the printing industry require accuracy for small details, speed to match high production volumes, flexibility for various materials and defects, and cost-effectiveness for long-term value.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace