Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

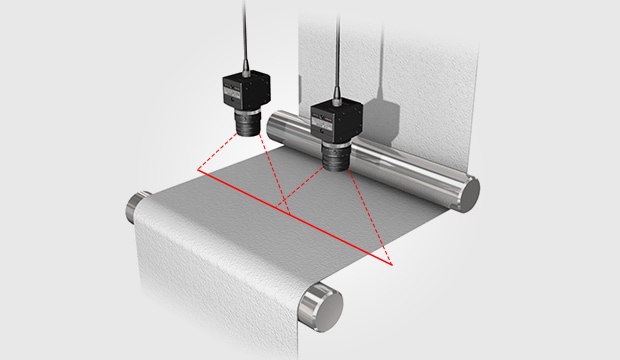

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Vision Systems for the Paper Manufacturing Industry

Precision is crucial for the paper manufacturing industry, as even the smallest defects can lead to significant waste and impact the overall quality of the final product.

KEYENCE has developed cutting-edge vision systems for paper manufacturing that combine high-performance cameras, advanced image processing algorithms, and AI technology to provide accurate and real-time detection of defects during production.

The VS Series is an AI vision system for the paper manufacturing industry, offering precise defect detection, efficiency, and enhanced product quality. Its user-friendly interface helps paper manufacturers optimize inspections.

We’re here to provide you with more details.

Reach out today!

Applications of Paper Manufacturing Vision Systems

Quality Control in Paper Manufacturing

Vision systems for paper manufacturing provide real-time monitoring and analysis throughout the production process, ensuring that the end product meets all the required specifications with respect to thickness, uniformity, color consistency, and the presence or absence of impurities or foreign materials.

By integrating AI technologies with high-resolution cameras and highly advanced image processing algorithms, vision systems are able to identify deviations from predefined standards with incredible accuracy.

Inspection of Paper Processing Equipment

The adequate calibration and performance of paper processing equipment directly affect production efficiency and product quality. Traditional inspection methods, which often rely on manual checks, are time-consuming and not reliable at detecting subtle yet critical calibration or performance issues early enough.

Paper manufacturing vision systems provide a more effective solution, as real-time monitoring is easily done via high-resolution cameras and lenses to detect signs of wear, misalignment, or malfunction before they’re even visible to the naked eye. This is important for preventive maintenance, as it minimizes downtime and extends the lifespan of paper processing equipment.

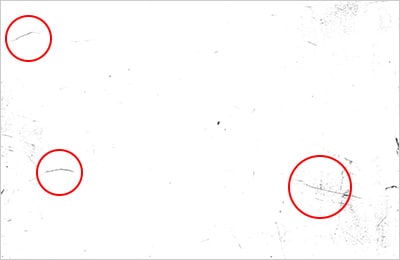

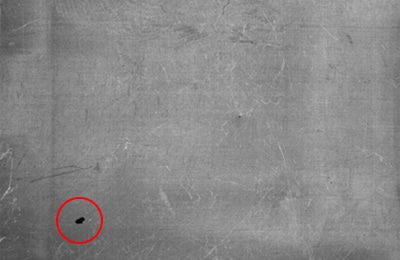

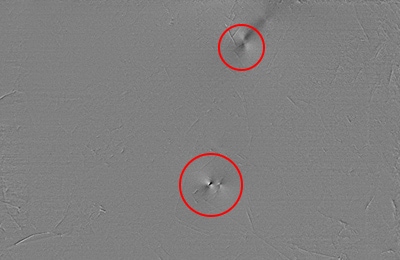

Surface Defect Detection in Paper Products

Achieving the flawless appearance of the final product is one of the most challenging aspects of paper manufacturing since any defects on the surface of the product significantly diminish the value of the end product.

High accuracy and precision of vision systems for paper manufacturing enable defect detection on paper surfaces during various stages of the production process. This ensures that only the top-quality paper reaches the customer and aids in diagnosing any underlying production issues that may lead to such imperfections.

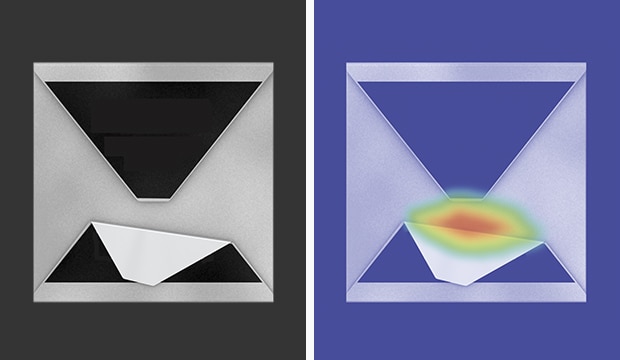

Specular reflection image

Gloss ratio image

Normal image

Diffuse reflection image

Shape image

Discover more about this product.

Click here to book your demo.

Introducing Our AI-Powered Vision System for the Paper Manufacturing Industry

The paper manufacturing industry depends on inspections to maintain product quality. Traditional manual methods are time-consuming and error-prone, struggling to meet the growing need for accuracy and speed. Our AI vision system for the paper manufacturing industry provides a transformative solution.

The VS Series uses advanced deep learning to detect defects in paper products like tears, holes, and discoloration. In addition to being a rules-based system, the VS can also adapt and learn from user provided datasets, delivering greater efficiency and flexibility.

Core Features:

- Accurate Inspection: Detects defects and deviations promptly during the production process.

- Scalable Integration: Seamlessly integrates with existing manufacturing systems to enable efficient automation.

- AI-Powered Analysis: Leverages advanced auto-focus algorithms to accurately read codes and identify flaws with precision.

- Optical Zoom: Mechanical zoom lenses enable optical zoom while maintaining full resolution quality.

Streamline inspections with the AI-powered VS Series vision system. Contact us to learn more or schedule a demo.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Vision Systems in the Paper Manufacturing Industry

What Are the Benefits of Using Vision Systems for the Paper Manufacturing Industry?

Vision systems for paper manufacturing provide several benefits to the production process, such as improved quality control, increased production efficiency, waste reduction, enhanced safety, cost savings, process control and optimization, and traceability and compliance.

What Types of Vision Systems Are Commonly Used in Paper Manufacturing?

Some of the most commonly used paper vision inspection systems are line scan cameras, area scan cameras, infrared (IR) and ultraviolet (UV) imaging systems, high-speed cameras, 3D vision systems, thermal imaging cameras, and smart cameras.

What Challenges Do Vision Systems Help Address in the Paper Manufacturing Industry?

Vision systems for paper manufacturing address a variety of challenges that affect the quality of the product and production efficiency. This includes detecting surface defects, checking color consistency and print quality, moisture content control, material waste reduction, process optimization, equipment monitoring, and batch tracking and traceability.

How Do Vision Systems Support Traceability and Compliance Requirements in the Paper Manufacturing Industry?

Vision systems for the paper manufacturing industry are also used for labeling, tracking, and tracing paper batches through the production process. This is important for quality control, inventory management, and compliance with traceability requirements.

What Are the Primary Considerations When Selecting Vision Systems for the Paper Manufacturing Industry?

The criteria for selecting vision systems for paper manufacturing largely depend on the applicational needs of particular manufacturing and production processes. The most common factors include resolution and image quality, speed and throughput, integration capabilities, ease of use, reliability and support, and costs.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace