Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Vision Systems for the Medical Device Manufacturing Industry

Explore our medical device manufacturing industry-focused vision systems designed to streamline quality inspection, assembly verification, and packaging inspections.

Given the direct impact on patient health and safety, the precision, reliability, and quality control required for medical devices are not just a necessity; they’re mandated by strict regulations. The implementation of machine vision systems for medical device manufacturing addresses those requirements through enhanced medical device inspection capabilities, quality assurance, and compliance with stringent regulatory standards.

The VS Series is an AI-powered vision system that optimizes industry processes through accurate visual analysis, allowing for rapid deployment for both inspection and guidance applications.

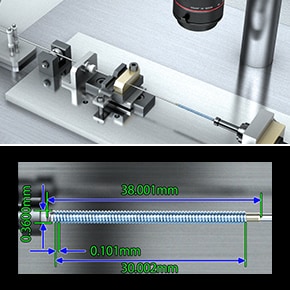

Stent length measurement for tool development

Identify parts and inspect for defects

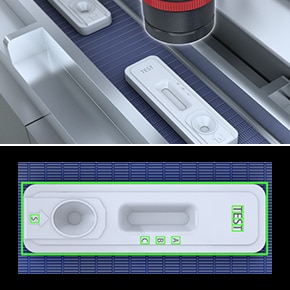

Diagnostic consumable - virus field test Kit (flu, dengue, etc.)

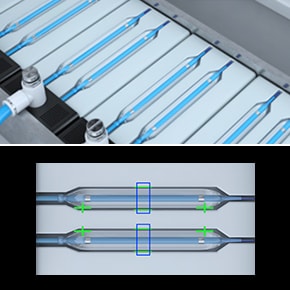

Center of contact lens

Applications of Medical Device Inspection Vision Systems

Quality Inspection for Medical Components

Medical device quality inspection is an important part of the medical device manufacturing process, and vision systems for medical device manufacturing play a crucial role in automating and enhancing inspection processes by relying on advanced imaging technologies, such as 3D scanning and imaging, automated optical inspection, and AI-driven machine vision solutions.

Assembly Verification in Medical Devices

Vision systems for medical device manufacturing use advanced imaging technologies and software algorithms to perform component presence and orientation checks, fit verification, and identification of potentially misaligned or defective parts during medical device assembly verification. This ensures that only the highest quality products reach the patients.

Packaging Inspection for Sterility

The integrity of medical device packaging is paramount, as any breach or improper sealing leads to contamination, which renders the medical device unsafe for use and potentially hazardous. Automated vision systems for medical device manufacturing play a crucial role in the packaging inspection process, ensuring the sterility and safety of the medical device.

Introducing Our AI-Powered Vision System for the Medical Device Manufacturing Industry

The medical device manufacturing industry is rapidly shifting towards automation and digitalization. AI in vision systems has revolutionized device inspection, providing unmatched accuracy and efficiency. The VS Series features AI-powered vision tools that learn from images, allowing for precise and adaptive inspections as products change. Our vision tools analyze large data-sets in real time, offering valuable insights into production processes and pinpointing areas for improvement.

Core Features:

- Zoomtrax: No loss of resolution, even when changing the field of view.

- Optimized Images: Create the best image for your project with one click.

- Edge AI: The use of Edge AI and a rule-based system allows for the right tool to be selected every time.

- Ease-of-use: The VS Series interface is organized and simple to use, making it easy for users of all skill levels.

Find out how our AI-powered VS Series vision system can improve your medical device manufacturing process today!

Applications and Examples

FAQs About Vision Systems in the Medical Device Manufacturing Industry

What Are the Benefits of Using Vision Systems for the Medical Device Manufacturing Industry?

Vision systems for medical device manufacturing bring numerous benefits to the industry as they directly address some of the unique challenges of medical device production. They provide unparalleled accuracy in detecting defects, imperfections, or variations from specified designs, and they can inspect thousands of devices or parts per hour, not to mention the elimination of human error, reduced downtime, and cost reductions.

What Types of Vision Systems Are Commonly Used in Medical Device Inspections?

The medical device manufacturing industry relies on numerous types of vision system implementation throughout production, each addressing the specific needs of different inspection tasks. This includes 2D and 3D vision systems, hyperspectral and multispectral imaging, and machine vision systems with integrated AI and machine learning.

What Challenges Do Vision Systems Help Address in the Medical Device Packaging Industry?

Vision systems for medical device manufacturing address several challenges associated with medical device manufacturing, like ensuring seal integrity, label accuracy and legibility verifications, contamination, and material defects detection, as well as challenges associated with regulatory compliance.

How Do Vision Systems Support Traceability and Compliance Requirements in the Medical Device Manufacturing Industry?

Besides performing quality control, vision systems for medical device manufacturing also document every product they inspect, supporting traceability and compliance requirements. This ensures the products can be traced throughout their entire life cycle. This includes:

- Unique device identification reading

- Data capture and storage

- Serialization compliance for quality inspection, regulatory adherence, and audit readiness

What Are the Primary Considerations When Selecting Vision Systems for the Medical Device Manufacturing Industry?

Selecting the right vision systems for medical device manufacturing is essential as it directly impacts product quality, regulatory compliance, and production efficiency. However, you need to consider application requirements, as those directly affect the necessary resolution and accuracy of your vision system, its speed, the types of inspections it can perform, and how well it can integrate into your manufacturing process.

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace