Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Vision Systems for the Marine Industry

With varying lighting conditions and complex structures, traditional inspection methods can be unreliable in the marine industry. These issues can lead to delays in production, increased costs, and safety hazards.

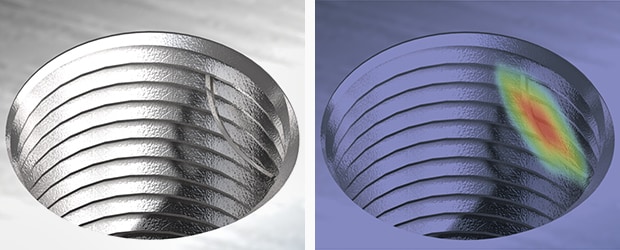

KEYENCE's vision systems for the marine industry can easily adapt to changing conditions and accurately inspect and carry out quality control of critical components. Our all-in-one smart cameras and high-speed controllers are designed to detect surface defects on metal parts and verify the dimensions of complex shapes.

The AI-driven VS Series vision system revolutionizes industrial processes with unparalleled accuracy, rapid setup, and effortless adjustments for focus and field of view, streamlining operations across marine industry applications.

We’re here to provide you with more details.

Reach out today!

Applications of Marine Vision Systems

Inspection of Ship Components

From hulls to engines, marine vessels need regular checks for safety and efficiency. KEYENCE's machine vision systems detect corrosion, cracks, and defects in components, preventing failures or malfunctions.

Quality Control in Shipbuilding

KEYENCE's AI-powered vision systems for the marine industry detect flaws in marine industry materials like steel plates, pipes, and welds, ensuring top quality in shipbuilding.

Discover more about this product.

Click here to book your demo.

Introducing Our AI Vision System for the Marine Industry

The VS Series redefines marine industry standards by enabling precise inspection of pipes, sails, and composite materials with advanced optical zoom technology. Its AI-powered precision detects flaws and potential issues, while rule-based adaptability ensures optimal quality. The intuitive software simplifies complex setups, enabling fast consistency checks and defect identification in marine components.

- Optimal Imaging in One Click: Achieve unparalleled image clarity for parts inspections with a single operation using AI vision inspection in the marine industry.

- ZoomTrax for Marine Materials: Seamlessly adapts to various surface materials without extra equipment.

- Dual Inspection Modes: Combines AI intelligence and traditional methods for superior defect and alignment detection.

- Real-Time Insights: Boosts efficiency and quality assurance with instant data visualization and analysis.

Elevate your inspections with the unmatched precision and adaptability of the VS Series, the leading AI vision system for the marine industry. Contact us today to get started.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Vision Systems in the Marine Industry

What Are the Benefits of Using Vision Systems for the Marine Industry?

High-resolution cameras and advanced algorithms allow marine vision inspection systems to carry out ship component defect detection, ensuring quality and preventing failures.

What Types of Vision Systems Are Commonly Used in Marine Manufacturing?

Some commonly used marine vision systems in manufacturing include smart cameras, line scan cameras, 3D cameras, and high-speed controllers.

What Challenges Do Vision Systems Help Address in the Marine Industry?

Vision systems in the marine industry use advanced technologies to address challenges such as quality control and safety inspections of critical equipment.

How Do Vision Systems Support Traceability and Compliance Requirements in the Marine Industry?

Vision systems for the marine industry utilize advanced image capture and processing technology to accurately identify and track products or components throughout production.

What Are the Primary Considerations When Selecting Vision Systems for the Marine Industry?

When choosing a vision system for the marine industry, consider the operating environment, inspection type, and any unique challenges or requirements unique to the application.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace