Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

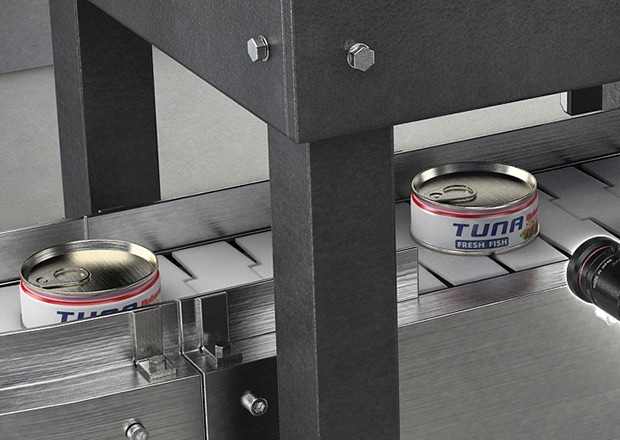

Can Inspection in Food and Beverage Packaging

KEYENCE takes pride in providing vision systems for food and beverage packaging applications. Our vision systems include the VS Series with built-in AI capability and the CV-X Series with intuitive controls for users of different skill levels. Within both of these systems, we also offer the 2D VGR Series hardware to equip industrial robots from major manufacturers with a powerful 2D guidance system.

KEYENCE vision systems are built with state-of-the-art technology for speedy can inspection to ensure compliance with quality and safety standards.

Key Inspection Points

Due to the presence of printing, it has often been difficult to perform defect inspections for dents on the side of cans. By using a line camera, it is possible to cancel the printing and only extract dents and stains.

OK image

NG image

We’re here to provide you with more details.

Reach out today!

Challenges in Can Inspection in Food and Beverage Packaging

Accuracy of Label

Misaligned labels on a product or packaging, missing bar codes, and ripped labels are potential applications for can inspection vision systems.

Container Integrity

Aluminum can inspection may be challenging due to cans containing defects, such as rust, dents, and holes. Can outer body appearance inspection helps accurately detect any of these irregularities.

Fill Level

Drinks or beverages not being filled to the correct level is a challenge in beverage production lines. Additionally, cans with missing vacuum seals can cause quality issues.

Foreign Object Detection

Contaminants and foreign materials such as metal swarf may be present in the soda or beer. Can inspection helps detect and search for these foreign materials.

Discover more about this product.

Click here to book your demo.

Vision Systems for Can Inspection in Food and Beverage Packaging

A common challenge in aluminum can inspections is detecting defects accurately. Dents on the inside or cuts on the outside of beverage cans may compromise the inner coating, letting the contents come in contact with exposed aluminum. This can give the beverage a bad taste and pose serious health hazards to consumers. With aluminum beverage cans accounting for 75% of global production, the exposure to aluminum in beverage factories is a significant concern.

KEYENCE offers vision products with high-resolution cameras and different technologies for unmatched appearance inspection.

Vision System with Built-in AI

KEYENCE VS Series combines Artificial Intelligence (AI) with the standard rule-based inspection model. Get superior detection results from KEYENCE AI vision systems.

-

1Camera Display

Intuitive Vision System

Our controller-based intuitive vision systems, like the CV-X Series, offer a user-friendly interface. Complete advanced inspections using interactive menus.

KEYENCE LumiTraxTM Technology

The KEYENCE LumiTraxTM technology provides stable detection for low-contrast targets like cast metal with stamped characters.

2D Vision-Guided Robotics

KEYENCE 2D vision guidance tools equip robots from all major manufacturers for grip correction and pick-and-place applications. The 2D VGR Series from KEYENCE is a 2D vision-guided robotics toolset suited for 2D guided applications.

Curious about our pricing?

Click here to find out more.

FAQs about Can Inspection in Food and Beverage Packaging

Why Is Appearance Inspection for the Outer Body of Cans Important in the Food and Beverage Industry?

Can outer body appearance inspection help detect dents that compromise aesthetic appeal and tiny ripples that may cut deep into the can.

How Does Aluminum Can Inspection Improve Product Quality?

Can visual inspection improves product quality by checking and detecting defects or contaminants that could cause bad taste or health complications.

What Are the Benefits of Using KEYENCE Vision System Technology for Can Appearance Inspection?

The KEYENCE vision system provides benefits such as high-resolution object detection, multi-spectrum image capturing, and built-in artificial intelligence capabilities.

What Are the Primary Defects of Aluminum Cans That Vision Systems Can Detect?

Basic aluminum can defects that vision systems can recognize include cuts, dents, ripples, and crushes.

Can KEYENCE Vision Systems for Aluminum Can Inspection Handle Different Can Shapes and Sizes?

Yes, KEYENCE machine vision systems can handle inspections of various sizes and shapes. The flexible camera and powerful vision components are adjustable.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace