Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

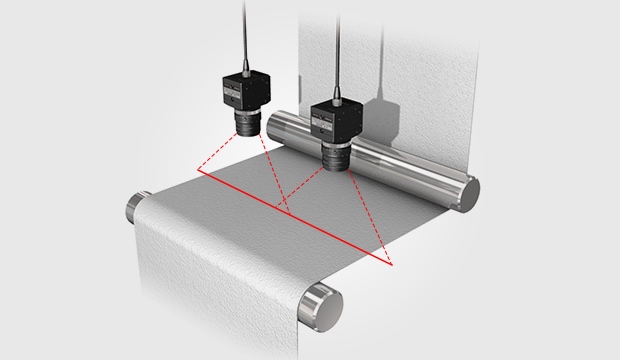

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Vision Systems for the Fabric and Textile Industry

Explore our fabric and textile industry-focused vision systems designed to streamline fabric inspections, color verifications, thread counts, and defect detections.

As expectations for quality, speed, and customization rise in the fabric and textile industry, manufacturers encounter challenges like defects, inconsistencies, and waste.

KEYENCE’s vision systems for the fabric and textile industry offer a comprehensive solution. They detect defects, measure dimensions, and maintain consistency in patterns and colors, from raw materials to finished products. With smart cameras, high-speed controllers, and AI-driven vision tools, we enable precise and efficient fabric inspections at every production stage.

Designed for adaptability, the VS Series integrates AI precision with a one-click focus, easy adjustments, and fast setup, ensuring seamless performance in fabric and textile industry inspections.

Applications of Fabric and Textile Vision Systems

Fabric Inspection and Defect Detection

AI and rule-based vision tools allow KEYENCE's fabric vision systems to quickly and accurately detect fabric defects. This not only ensures a high-quality end product but also saves manufacturers time and resources.

Color Matching and Verification in Textile Printing

KEYENCE's vision systems for the fabric and textile industry are equipped with advanced color inspection technology, allowing for precise color detection/matching and verification in real time, ensuring consistency throughout the production process.

Thread Count Measurement for Textile Products

Traditional manual methods for measuring thread count are slow and error-prone. KEYENCE's textile vision inspection systems use high-speed cameras and advanced algorithms for quick and accurate measurements.

We’re here to provide you with more details.

Reach out today!

Introducing Our AI Vision System for the Fabric and Textile Industry

The VS Series, an AI vision system for the fabric and textile industry, revolutionizes inspection with its cutting-edge optical zoom, which makes it possible to examine complex colors and patterns. By combining AI-driven precision with rule-based adaptability, it finds inconsistencies and ensures superior quality. Software that is easy to use makes setup simpler and enables quick consistency checks and defect detection.

- ZoomTrax for Versatile Adaptability: Revolutionary optical zoom seamlessly adjusts to diverse textile patterns without manual setup or extra tools.

- Dual AI and Rule-Based Tools: Identify defects, patterns, or alignments in fabrics using advanced AI or traditional inspection methods.

- Streamlined Setup for Complex Fabrics: Quickly configure inspections for intricate textile designs with user-friendly software and task-specific programming.

- Real-Time Data for Quality Assurance: Instantly analyze and manage inspection data to improve textile production efficiency and consistency.

Explore how the VS Series can elevate inspection processes with its advanced artificial intelligence vision systems in the fabric and textile industry by contacting us today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Vision Systems in the Fabric and Textile Industry

What Are the Benefits of Using Vision Systems for the Fabric and Textile Industry?

Vision systems in the fabric and textile industry can quickly identify defects and irregularities in fabric or textile products, allowing for faster production and reduced waste.

What Types of Vision Systems Are Commonly Used in Fabric and Textile Manufacturing?

There are several types of fabric vision systems that are commonly used, such as smart cameras, modular high-speed controllers for 2D, line scan, and 3D cameras.

What Challenges Do Vision Systems Help Address in the Fabric and Textile Industry?

Vision systems for the fabric and textile industry help overcome various challenges like consistent quality control, detecting defects or flaws in fabrics, and increasing production efficiency.

How Do Vision Systems Support Traceability and Compliance Requirements in the Fabric and Textile Industry?

Textile vision inspection systems can support traceability and compliance by providing accurate and consistent data collection and analysis by capturing detailed images of every step in the production process.

What Are the Primary Considerations When Selecting Vision Systems for the Fabric and Textile Industry?

Several key factors include accuracy, speed, versatility, ease of use, reliability, and integration with existing equipment.

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace