Coding in Baked Goods Packaging Industry with UV Laser Technology

As a popular substitute for conventional thermal transfer overprinters (TTO), UV laser printers improve the efficiency of coding in the baked goods packaging industry. Manufacturers can guarantee traceability and long-lasting product information with accurate, permanent coding without changing current films or equipment. Consumables are no longer necessary, lowering waste, downtime, and expenses.

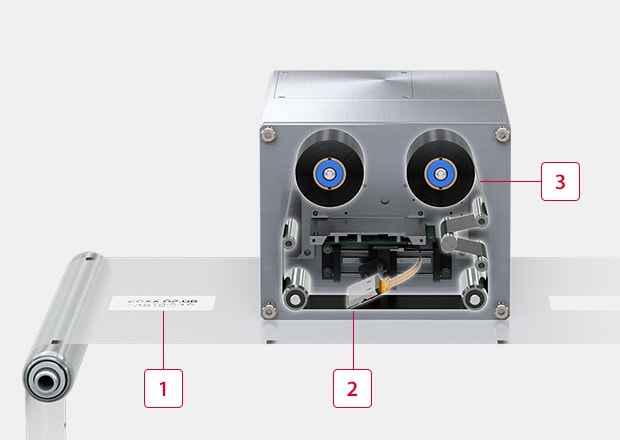

Conventional thermal printer

-

1Risk of marking that fades

-

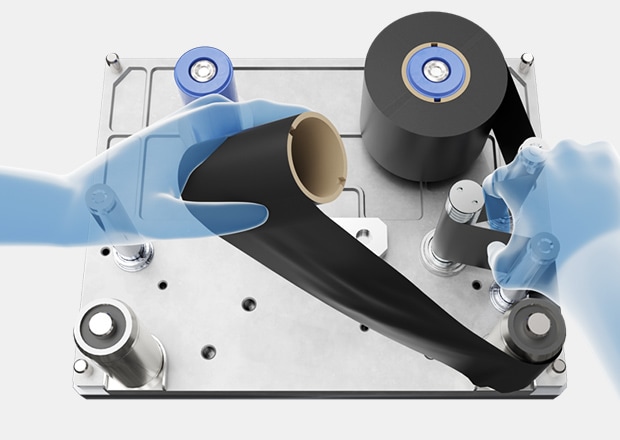

2Thermal head replacement

-

3Ink ribbon replacement required

UV laser coders

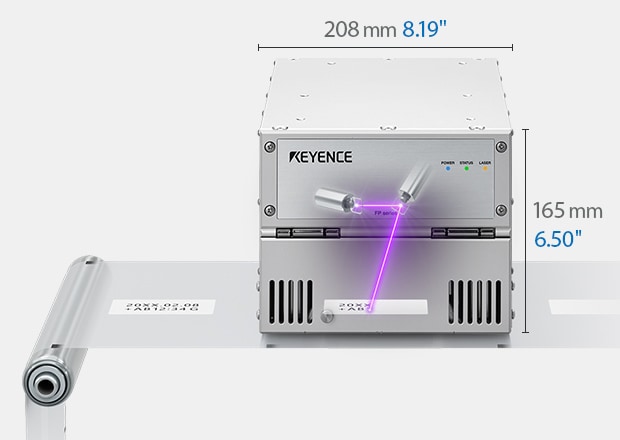

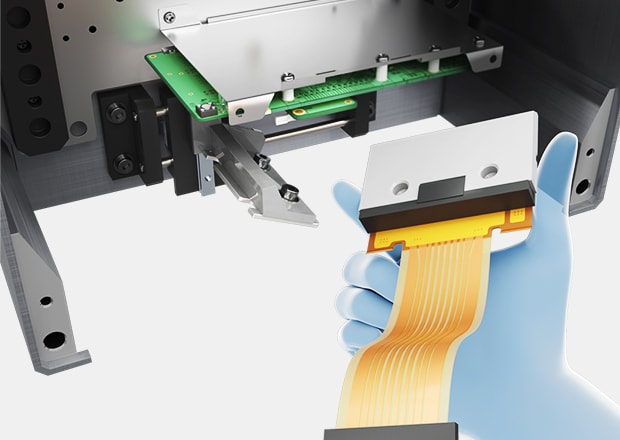

Replacement of current TTO is simple due to similar outer dimensions.

We’re here to provide you with more details.

Reach out today!

UV Laser Coding and Marking in Baked Goods Packaging Industry

KEYENCE’s FP-1000 Series UV laser coder is tailored for marking on baked goods packaging materials, such as multilayer films, foils, and paper-based materials. It is ideal for baked goods products like:

- Cookies

- Granola Bars

- Muffins

- Brownies

- Pastries

- Donuts

- Biscuits

Curious about our pricing?

Click here to find out more.

Baked Goods Packaging Industry-Specific Challenges Solved by FP-1000 Series Technology

Eliminate Expensive Consumables

Methods like thermal transfer overprinting require ribbons and print heads, increasing operational costs. With its light-based technology, the FP-1000 Series does away with these consumables, reducing costs.

No ink ribbon costs

No head replacement costs

Reduce Costly Downtime

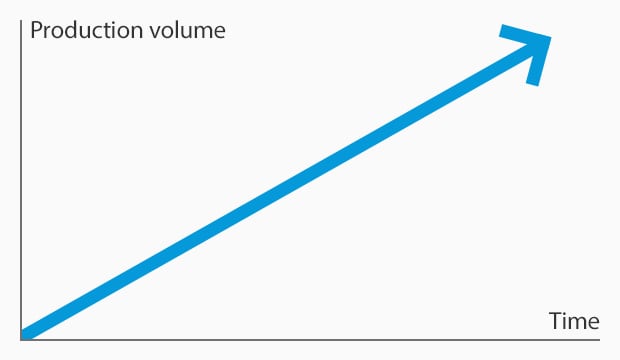

Frequent production interruptions for ribbon and part replacements in TTO systems disrupt efficiency. The FP-1000 Series’ non-contact, consumable-free marking minimizes downtime, allowing continuous operations in high-demand baking lines.

Continuous production with no need to stop lines

Continuous Marking with a UV Laser

Downtime is a thing of the past with UV laser coders, enabling more production in the same amount of time and faster production for the same amount of targets.

Zero Consumable Costs with a UV Laser

UV laser coders use light for marking, eliminating daily consumables costs. There are also no parts requiring periodic replacement, eliminating periodic maintenance and inspection costs as wells.

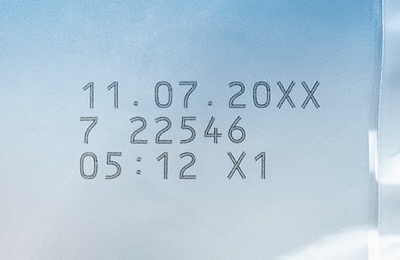

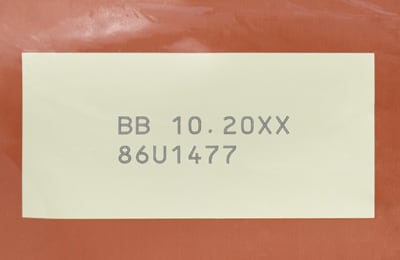

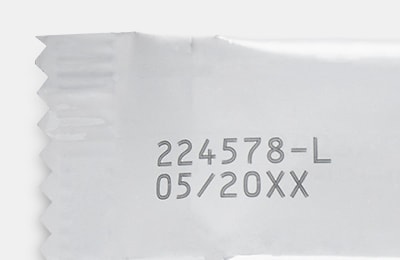

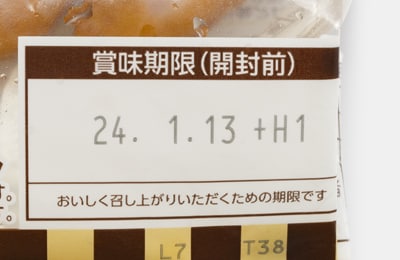

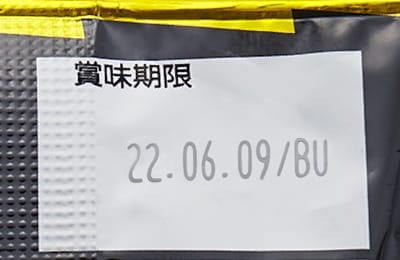

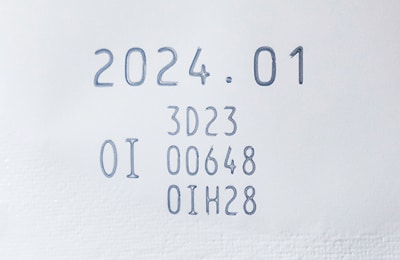

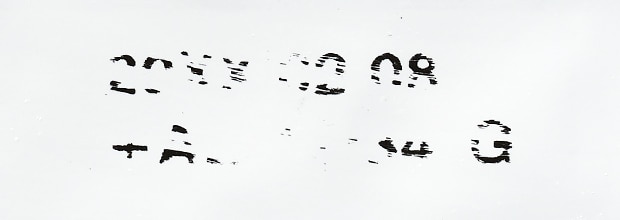

Create Permanent Marks

Fading codes on packaging can lead to traceability issues, especially in baked goods. Batch numbers, expiration dates, and other important information are consistently readable thanks to the FP-1000 Series' permanent, high-contrast markings on materials like film and foil.

UV lasers are not affected by traditional causes of marking that fades away:

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

Support Sustainability

Packaging waste is a concern in the baked goods industry. By removing consumables and increasing operational efficiency, the FP-1000 Series UV laser coding and marking on baked goods packaging lowers waste and supports sustainability objectives.

Disposal loss simulation:

For a facility that replaces four ink ribbons per day, operating at 25 days per month will lead to disposal of 1,200 ink ribbons per year. At 500 grams 17.65 oz per ink ribbon, 1,200 ink ribbons would equal 600 kilograms 1322.76 lb, or about 1.2 tons of CO2 emissions upon disposal. UV laser coders, however, do not use ink ribbons, so the CO2 emissions can be reduced to zero.

Why Choose the FP-1000 Series for Baked Goods Packaging Industry Marking Needs?

The FP-1000 Series offers high-speed, reliable UV laser coding tailored for baked goods packaging laser marking needs. By applying long-lasting, permanent markings to packaging materials without the use of consumables, its non-contact technology lowers waste and operating expenses. The FP-1000 Series is made to integrate seamlessly, reducing downtime and increasing production efficiency. Improve your business processes with accurate, environmentally friendly coding that advances sustainability objectives. Contact us to learn how a UV laser coder can transform your packaging line.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Technology in Baked Goods Packaging Industry

How Does the FP-1000 Series Ensure Damage-Free Marking on Baked Goods Packaging?

The FP-1000 Series uses non-contact UV laser technology that produces clear, permanent marks without compromising the integrity of packaging materials like films or paper wraps.

How Easy Is It to Install the FP-1000 Series on Existing Baked Goods Packaging Lines?

Designed for seamless integration, heads are compact for easy installation on existing equipment, with straightforward software and hardware setup.

Why Do Food Manufacturers Prefer UV Laser Coding for Baked Goods?

Consistent, long-lasting markings provided by UV laser coding preserve traceability while lowering expenses related to consumables like ribbons and ink.

What Makes UV Laser Coding Better Than Conventional Thermal Transfer Printers for Baked Goods Packaging?

In contrast to thermal transfer printers, UV lasers produce high-quality, long-lasting results while reducing downtime and consumables.

What Are the Environmental Benefits of UV Laser Coding for Baked Goods Packaging?

Without the need for ribbons and cartridges, UV laser coding in the baked goods industry promotes environmentally friendly operations while preserving product markings.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)