Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

CIJ for the Pharmaceutical and Consumer Products Industry

The pharmaceutical and consumer products industry is highly regulated and requires strict adherence to quality standards. Companies in this industry face challenges that can result in delays, errors, and product recalls.

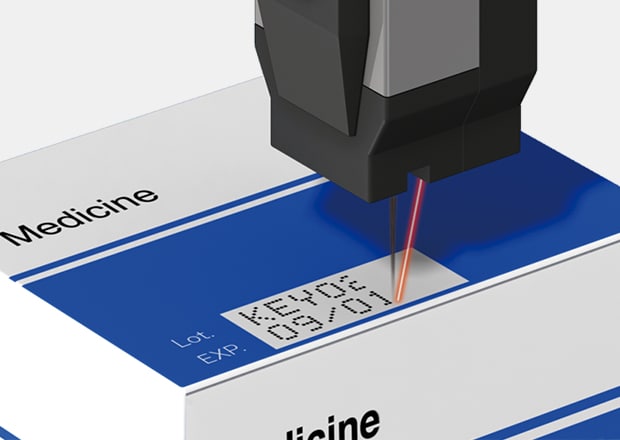

KEYENCE's MK-G Series of CIJ printers offer safe and reliable coding solutions. They easily integrate into facilities with limited space and have a variety of features that specifically benefit the pharmaceutical and consumer products industry.

Glass containers

PET bottles

Pouches

Form-filled packages

Heat-sealed packages

Cartons

We’re here to provide you with more details.

Reach out today!

Applications of Date Coding on Pharmaceutical and Consumer Products Packaging

Cosmetics, Personal Care and Home Care

For products with strict regulations, accurate and legible coding is essential. KEYENCE CIJs integrate seamlessly into production lines, increasing uptime, product safety, and traceability with high-speed capabilities and minimal maintenance.

Click here to see "Coding in the Cosmetics, Personal Care, and Home Care Industries"

Printing example

Installation example

Pharmaceutical and Medical Devices

Installation example

Pharmaceutical and medical device packaging have strict global standards for clear lot and pharmaceutical date coding. KEYENCE's world-leading sensing solutions monitor breakpoints for flawless dot quality, delivering consistent print quality with its solvent-based ink system.

Click here to see "Coding on Pharmaceutical and Medical Device Packaging"

Tobacco

Tobacco products need traceability and coding because of regulations and health warnings. KEYENCE’s MK-G Series can withstand harsh tobacco packing environments, featuring automatic cleanings to reduce skilled technician tasks and add protection.

Cannabis

Cannabis legalization has spurred a rapidly growing industry reliant on coding for tracking, traceability, and safety regulations. The MK-G Series provides easy integration and operation for manufacturing facilities, featuring ease of use and built-in diagnostics.

Paper Products

A challenge with coding and marking on paper products is maintaining legibility over time, as paper can wear and be affected by environmental factors that cause markings to fade or smudge.

Click here to see "Coding on Paper Products"

Nutraceuticals

Nutraceuticals often come in smaller packaging due to their concentrated nature, leaving less space for essential information.

Click here to see "Coding on Nutraceutical Packaging"

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About CIJ in the Pharmaceutical and Consumer Products Packaging Industry

What Are the Key Advantages of Using KEYENCE Continuous Inkjet Printers for the Pharmaceutical and Consumer Product Packaging Industry?

The advantages of using KEYENCE CIJs in the pharmaceutical and consumer products industry are uptime, ease of use, robustness, print quality, reduced running costs, and reduced human interaction (less user error).

What Features Differentiate KEYENCE Continuous Inkjet Printers for the Pharmaceutical and Consumer Product Packaging Industry?

KEYENCE CIJs stand out with industry-first features like a Backup Power Module, MIL standard-compliant impact resistance, Smart Startup, and free printer monitoring network connectivity.

Other features include:

- Wide range of inks

- Quick-dry

- Non-contact

- Self-troubleshooting

- Minimal exposure to ink and solvent

- Remote operations

- Event recording function

What Impact Do Continuous Inkjet Printers Have on Production Efficiency and Downtime in the Pharmaceutical and Consumer Product Packaging Industries?

KEYENCE continuous inkjet printers deliver high-quality, reliable printing of regulatory codes, enhancing safety by reducing chemical exposure for staff and products. This ensures less downtime for more efficient processes.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)